50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | MS3113B | |

|---|---|---|

| Max.. length of mortise | MM | 130 |

| Max.. depth of mortise | MM | 60 |

| Max.. width of mortise | MM | 16 |

| Spindle speed | r / min | 15200 |

| Puissance totale | KW / HP | 2.2/3 |

| Hunting frequency | times/min | 170-230 |

| Air pressure | MPA | 0.4-0.6 |

| Dimensions globales | MM | 1480*1150*1250 |

| Poids | kg | 550 |

1. The fuselage is made of high-quality steel plates welded and processed, and the performance is stable.

2. The spindle adopts high-precision heavy cutting structure, and the spindle speed reaches 15000r/min, with high efficiency.

3. The tenon and groove swinging mechanism adopts the structure of precision cylindrical guide rail sliding bearing, and is equipped with a hand pressure lubricating pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

4. The tongue and groove width adjustment adopts digital display, manual adjustment, simple operation and more accurate processing.

5. The adjustment of the spindle swing speed adopts the friction wheel tensioning speed adjustment structure to adjust the speed to meet the processing needs of various materials.

6. The tenon and groove operation adopts double worktables alternately, and the worktable can process the inclined tenon and groove at an inclined angle.

This product is mainly to meet the needs of tongue and groove processing of solid wood doors, tables and chairs.

This mortising machine is an economical and practical horizontal double-end slotting machine. The maximum tongue groove width is 130mm, the maximum groove depth is 60mm, and the maximum deep groove width is 16mm. The product has stable performance, simple operation, convenient maintenance and high cost performance. It is an economical and applicable equipment for groove processing in the solid wood processing industry.

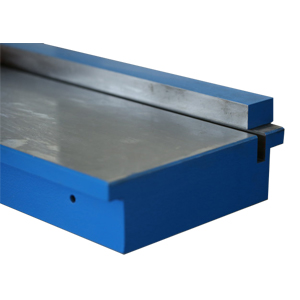

customized table

Le tableau de travail de notre 4 Le moulin à planeur latéral peut être allongé, longueur personnalisée en fonction de vos exigences.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

Système de convoyeur

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, Nous pouvons combiner 4 Planeur à côte avec un système de travail et de hors-d'alimentation.

Outils de coupe

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

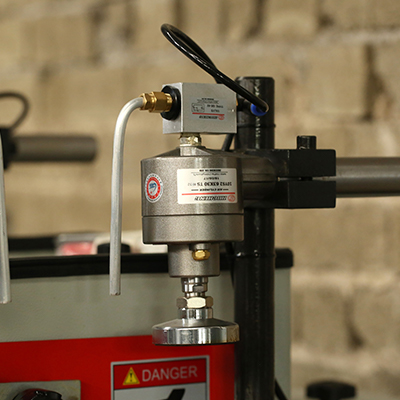

HIGH PRECISION SPINDLE

The spindle adopts a high-precision heavy-cutting structure, and the spindle speed reaches 15000r/min, which meets the needs of high efficiency in mortising processing.

GUIDE RAIL

The mortising mechanism adopts a precision cylindrical guide rail sliding bearing structure, and is equipped with a hand pressure lubrication pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

CONVENIENT ADJUSTMENT

The width of the mortising adopts digital display, manual adjustment, simple operation, convenient adjustment and more accurate processing.

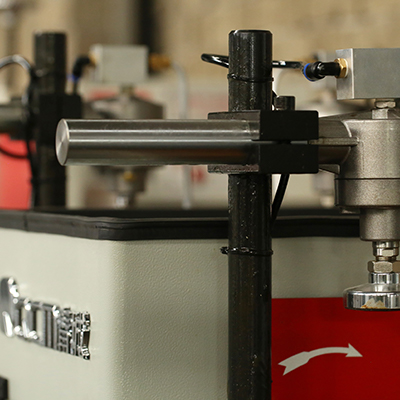

SPINDLE SPEED ADJUSTMENT

The adjustment of the spindle swing speed adopts the friction wheel tension adjustment speed structure to adjust the speed to meet the processing needs of various materials.

DOUBLE WORKBENCHES

The mortising operation adopts double workbenches to work alternately, and the workbench can be inclined to process the oblique mortise.