Nom de produit: double-end Squaring, Milling & Sanding Machine QMXK1225JS

Application: door making, wooden flooring, for wooden furniture production and interior furnishings

Fonctions: squaring, trimming, sanding

Fuseau: 6 Fuseau

50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

This high-performance double-end tenoner can be configured as required to tackle a host of different tasks: angle cuts, bevel cuts, profilage, rabbeting, grooving, sanding and corner processing. Thanks to its robust design, low-wear technology and high level of availability, this double end tenoning machine machine is exactly the right choice for manufacturing doors, fronts and panels.

• User-friendly PLC control

• Width setting through touch-sensing screen for increased accuracy and convenience

• Moulding spindle is directly driven by a high-frequency motor, providing 7,500 rpm spindle speed

• Link chains are driven by a frequency-inverted motor, ensuring synchronized feed at both sides

• 6 et 8 fuseau (optional)

Double end tenoner provides the best way to productivity and versatility

• The double end tenoner is designed and engineered for high quality wooden furniture with profitable production.

• They are ideal for producing solid wood and panel furniture and wooden doors.

• The series of double end tenoner provides various functions, such as double end sizing, profile moulding. It’s a highly automated machine that creates the efficiency you’ve come to expect.

largeur de traitement personnalisée

La largeur de traitement de la tenonneuse double extrémité peut être personnalisée selon vos besoins. 3000mm est également disponible.

Outils de coupe

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

Système de convoyeur

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, Nous pouvons combiner 4 Planeur à côte avec un système de travail et de hors-d'alimentation.

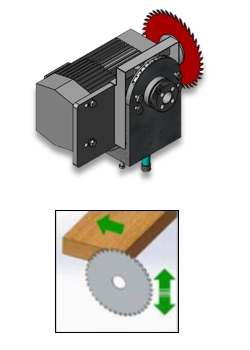

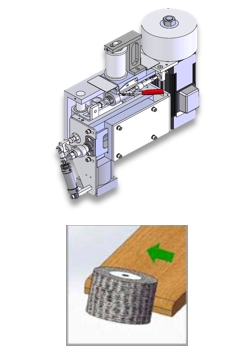

1ST SPINDLE

- Lower Saw Shaft (with retractable blade).

- High-speed variable frequency motor.

- Adjustable angle.

Separated groove (scoring) saw .

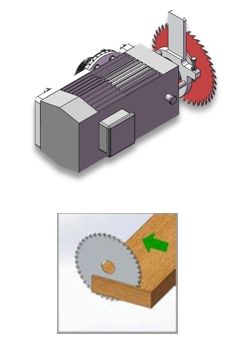

2ND SPINDLE

- Upper Saw Shaft.

- High-speed variable frequency motor.

- Adjustable angle.

- Separated break saw.

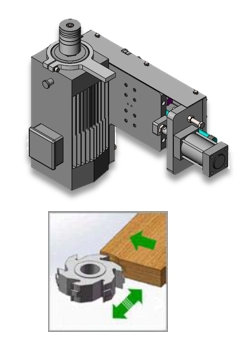

3RD SPINDLE

- Milling Cutter Shaft.

With retractable blade function. - Adjustable angle.

- Equipped with high-speed variable frequency motor .

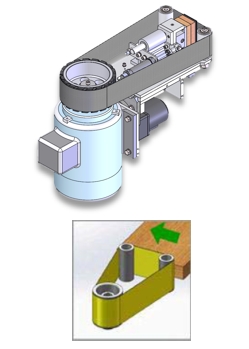

4th SPINDLE

- Milling Cutter Shaft.

- High-speed variable frequency motor.

- Adjustable angle.

5TH SPINDLE

- Triangular Sanding. Frame Assembly

- Sanding wheel center distance: 200MM.

- Automatic belt oscillation function.

- Sanding pressure block with compensation function.

6TH SPINDLE

- Multi-purpose sanding head device.

- Capable of flat sanding or profile sanding.

- Equipped with automatic compensation function.