Nom de produit: machine à tenonner les doubles extrémités, double-end tenoner MXK3812A

Application: meubles en bois, table, chair

Fonctions: double-end milling square tenon, oblique tenon, round tenon, oval tenon.

Working Length: 250-1200MM

Largeur de travail: 10-115MM

Épaisseur de travail: 10-60MM

Max.. Length of Tenon: 40(70mm optional)

50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | MXK3812A | MXK3821A | |

|---|---|---|---|

| Working lenght | MM | 250-1200 | 200-2100 |

| Largeur de travail | MM | 10-115 | 10-160 |

| Max.. processing thickness of tenon | MM | 20 | 20 |

| Max.. tenon lenght | MM | 40 | 40 |

| Milling tenon speed | r / min | 12000 | 12000 |

| Milling spindle dia. | MM | φ30 | φ30 |

| Puissance totale | KW / HP | 11.4/15 | 13.2/18 |

| Diamètre de la hottes. | MM | 2*φ100 | 4*φ100 |

| Dimensions des machines | MM | 2650*1400*1700 | 2650*1400*1700 |

| Poids | kg | 1950 | 1950 |

1. The bed is cast as a whole with high-quality castings, with stable performance and good precision;

2. The milling shaft adopts the frequency conversion motorized spindle, which is suitable for the processing of wood products of different materials and hardness;

3. The original swinging hinge feeding mechanism realizes fast feeding and low failure rate;

4. Using hopper feeding to realize automatic feeding;

5. The X-axis and Y-axis can be inclined at an angle, which can be used for inclined milling operations;

6. Equipped with automatic lubricator to ensure smooth operation;

7. Optional: It can be lengthened by 2200mm according to the requirements of the user’s bedroom furniture bed, the model is MXK3820A.

This machine is a CNC automatic double-end tenon milling machine. It is to meet the needs of the solid wood processing industry for safety, efficiency and reduction of labor. Especially in the dining table, dining chair, solid wood furniture industry, the demand for batch efficient processing. Two-axis linkage CNC double-end milling square tenon, oblique tenon, round tenon and ellipse tenon, It has the advantages of simple operation, convenient and fast, efficient processing and good quality. It is an ideal equipment for large-scale production, expansion of production capacity, and file upgrades in the solid wood furniture, dining table, and dining chair industries.

largeur de traitement personnalisée

La largeur de traitement de la tenonneuse double extrémité peut être personnalisée selon vos besoins. 3000mm est également disponible.

Outils de coupe

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

Système de convoyeur

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, Nous pouvons combiner 4 Planeur à côte avec un système de travail et de hors-d'alimentation.

FONTE ENTIÈRE

Une pièce extra lourde, Le cadre de la machine en fonte est spécialement traité thermiquement pour une stabilité et une rigidité maximales grâce à la configuration standard.

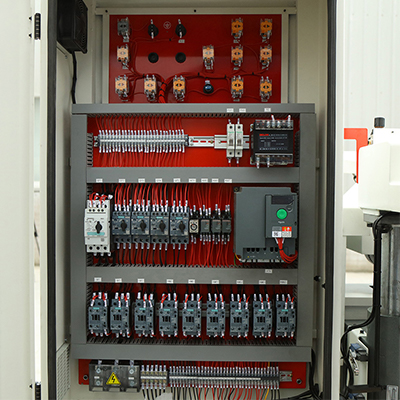

Siemens Electrical

Les produits et appareils électriques Siemens et Schneider garantissent le bon fonctionnement de l'ensemble de la machine avec des performances stables

MOUVEMENT SYNCHRONE

Les mouvements de largeur de la table de travail utilisent un guide linéaire importé et une structure de réglage automatique de la largeur CNC qui présente une caractéristique de réglage facile, positionnement précis et excellente capacité d'usure.

CONTRÔLE AVANCÉ PAR API

Le système d'exploitation est équipé d'un écran tactile d'ordinateur importé et d'un PLC pour un contrôle conjoint, qui est intuitif et pratique à utiliser, ce qui peut réduire efficacement le temps d'ajustement et améliorer l'efficacité de la production.