50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | MXK3155A | |

|---|---|---|

| Largeur de travail | MM | 500 |

| Épaisseur de travail | MM | 12-25 |

| Spindle speed | r / min | 18000 |

| Puissance totale | KW / HP | 3/4 |

| Power of spindle motor | KW / HP | 1.1/1.5 |

| X-axis motor | KW / HP | 0.75/1 |

| Y-axis motor | KW / HP | 0.75/1 |

| Cutting period | s | 3-30 |

| Dimensions globales | MM | 1700*750*1250 |

| Poids | kg | 600 |

1. The X and Y axes adopt imported linear guides and ball screw drive structure, with flexible movement, stable performance and good precision.

2. The X and Y axes adopt Delta’s high-efficiency full-servo drive system. It runs smoothly and has stable performance.

3. Adopt the international brand Delta motion controller and touch screen control to realize the man-machine interface, the operation is simple and easy to learn, and no special training is required. The parameters can be easily input and modified through the touch screen, and the tool wear can be compensated. The operation is simple, convenient and fast.

4. Each group of the pressing system is equipped with 4 pressing cylinders to ensure stable pressing and good processing quality.

5. Additional functions: Change the tool to reset the program, and can perform tenon processing of different shapes such as round tenon, waist tenon and square tenon.

This CNC dovetail tenoning machine is mainly to meet the needs of processing dovetail tenons in the solid wood furniture manufacturing industry. The maximum processing width is 500mm, and the maximum processing thickness is 25mm. It has the advantages of stable performance, high processing efficiency and high cost performance. It can process not only various dovetail tenons, but also various shapes of tenons. It is mainly used in the furniture manufacturing industry to process the drawer coaming dovetail tenon at one time. It is an ideal equipment for efficient processing in solid wood furniture manufacturing industry.

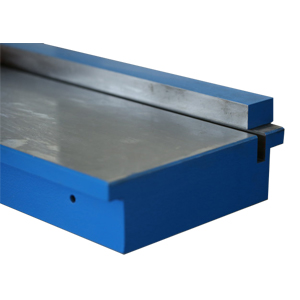

customized table

Le tableau de travail de notre 4 Le moulin à planeur latéral peut être allongé, longueur personnalisée en fonction de vos exigences.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

Système de convoyeur

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, Nous pouvons combiner 4 Planeur à côte avec un système de travail et de hors-d'alimentation.

Outils de coupe

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

AUTOMATIC LUBRICATORE

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

GOOD DRIVE STRUCTURE

X, Y axis adopts imported linear guide rail and ball screw drive structure, which has flexible movement, stable performance and good accuracy.

HIGH EFFICIENCY DRIVE SYSTEM

The X, Y axis adopts Delta’s high-efficiency full servo drive system. It runs smoothly and has stable performance.

SIMPLE OPERATION

Adopt international brand Delta motion controller and touch screen control, the operation is simple and easy to learn. And tool wear can be compensated. The operation is simple, convenient and fast.

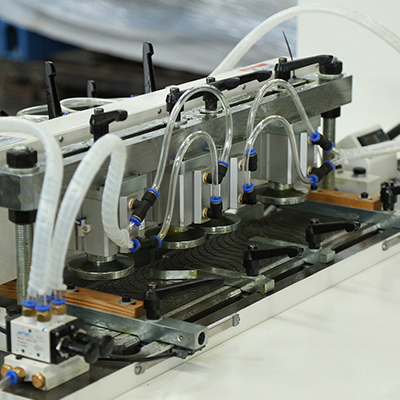

PRESSING SYSTEM

Each group of pressing system is equipped with 4 pressing cylinders to ensure stable pressing and good processing quality.