50+ خبرة سنوات

3 ضمان سنوات

الدعم الفني 7*12H

المعيار والموحدة

| تحديد | QMJ145H | QMJ143S | QMJ143E | MJ1440e | |

|---|---|---|---|---|---|

| الأعلى. عرض العمل | مم | 500 | 300 | 300 | 300 |

| سمك العمل | مم | 10-170 | 10-85 | 10-120 | 10-115 |

| دقيقة. طول العمل | مم | 740 | 530/200 | 600/300 | 450 |

| رأى ضياء المغزل. | مم | Φ60 | Φ55 | Φ55 | φ50 |

| تقليل ضياء الأكمام. | مم | Φ80 | Φ70 | Φ70 | Φ70 |

| رأى سرعة المغزل | ص/دقيقة | 2600 | 4000 | 4000 | 4500 |

| سرعة التغذية | م/بلدي | 3-24 | 4-30 | 4-30 | 6-24 |

| القوة الكلية | KW/HP | 81.25/109 | 32.57/43.5 | 39.57/52.7 | 33.32/45 |

| شفط غطاء محرك السيارة. | مم | 2*Φ150 | 2*Φ150 | 2*Φ150 | 2*Φ150 |

| الأبعاد العامة | مم | 4850*2020*1880 | 1930*1580*1560 | 2200*1500*1580 | 2300*1190*1480 |

| وزن | كجم | 4250 | 2250 | 2300 | 1900 |

1. جسم آلة المنشار متعدد الشفرات ومنضدة العمل مصنوعان من مصبوبات عالية الجودة, والتي يتم صبها خصيصًا وتصنيعها بدقة, مع أداء مستقر ودقة جيدة.

2. The conveyor chain and guide rail ofmulti-blade rip saw machineare made of special wear-resistant materials, which are specially processed and precision machined, with long service life;

3. The upper and lower triple anti-bounce device is equipped to ensure safe and reliable operation;

4. The spindle ofmulti-blade rip saw machineis made of special material, precision processing, علاج التوازن الديناميكي, and precision assembly, stable operation and high precision;

5. Equipped with imported microcomputer automatic oil injection pump with timed, fixed point and quantitative lubrication, with oil shortage shutdown protection to ensure normal use and life of the machine;

6. Imported large torque transmission deceleration box, strong and powerful feeding;

7.Configured with side protection and power failure device to fully protect human and machine safety;

8. All electrical components and transmission parts are of good brands and components, stable performance;

9. Feeding adopts frequency conversion to adjust the speed, adapting to a variety of materials and thickness of wood processing requirements.

الحل المهني: make multi-blade rip cut for thick wood under 120mm. Heavy and stable casting machine body, and equipped with advanced V guide and chain plates, and the saw shaft has sufficient strength and rigidity to do multi-slice rip cut. Perfect for pencil, and similar small wooden products.

We have different type of multi-blade rip saw machine, مثل QMJ143E, QMJ145H, QMJ143S, QMJ1440E.

منشار مغزلي واحد أو مغزلين (آلة منشار التمزق لأعلى ولأسفل) متوفرة, بعرض العمل من 200-500 مم.

محرك مخصص

في جدول المعلمات الفنية لدينا 4 سوي على الوجهين متلهف, يمكنك رؤية التكوين القياسي لدينا. إذا كنت بحاجة, يمكننا ترقية طاقة المحرك لك.

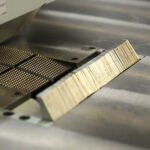

رأى بليد

لا تحتوي معظم آلات النجارة الخشبية على أدوات القطع عند التصدير, لأن مصانع النجارة المختلفة تحتاج إلى نوع مختلف من القواطع. لتحسين خدمتنا, يمكننا مساعدتك في شراء أدوات القطع.

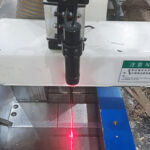

دليل الليزر

For straight line rip saw and single-blade rip saw, سيضيف العملاء دليل ليزر لقطع أفضل, سيكون القطع أكثر دقة. The straight line will be more straight.

حديد الزهر بالكامل

قطعة واحدة ثقيلة جدًا, يتم معالجة إطار آلة الحديد الزهر بالحرارة خصيصًا لتحقيق أقصى قدر من الثبات والصلابة من خلال التكوين القياسي.

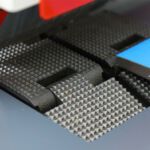

جهاز أمان مضاد للارتداد

يضمن جهاز الأمان المضاد للارتداد الموجود على وحدة التغذية السلامة التشغيلية.

مسار دليل مقاومة التآكل

إن مسار دليل الصب ولوحة السلسلة مصنوعان من مواد خاصة, معالجتها خصيصا ومعالجتها بدقة, مع صلابة سطحية عالية, دقة عالية ومقاومة جيدة للتآكل

التشحيم التلقائي

يوفر جهاز التشحيم الأوتوماتيكي زيت تشحيم متكرر لسلسلة كاتربيلر.

فرشاة إزالة الغبار

تتوافق فرشاة إزالة الغبار المصنوعة من مواد خاصة مع جهاز حقن الزيت الكمي لتنظيف وتشحيم ألواح السلسلة في الوقت الفعلي

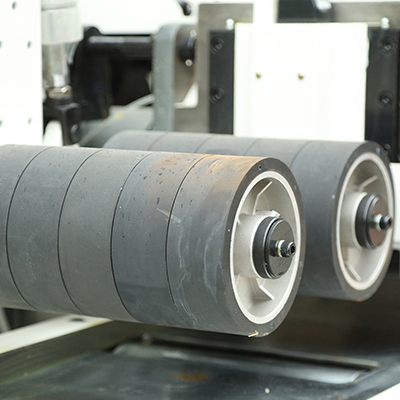

مغزل عالي الدقة

تم تصنيع جميع المغازل بدقة ومعالجتها حراريًا خصيصًا لتوفير أقصى قدر من ثبات القطع والدقة الدائمة.

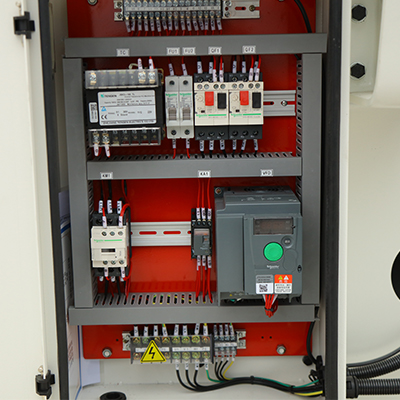

الأجهزة الكهربائية المهنية

تضمن المنتجات والأجهزة الكهربائية Siemens وSchneider أن الآلة بأكملها تعمل بشكل جيد مع أداء مستقر

طاولة تغذية من الحديد الزهر ومطلية بالكروم

تتم معالجة طاولة التغذية المصنوعة من الحديد الزهر المطلية بالكروم بالكامل بالحرارة لتحقيق أقصى قدر من الاستقرار. جدول التغذية & يتم تعديل السياج بسرعة عن طريق أذرع الإعداد السريع.