خط إنتاج كريات الكتلة الحيوية مشروعك

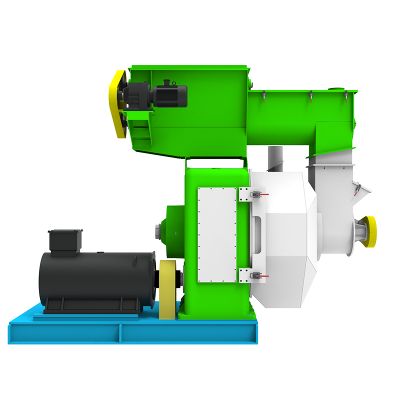

آلة بيليه الكتلة الحيوية هي المعدات الأساسية في خط إنتاج تصلب وتشكيل الكتلة الحيوية. إنها تصنع كريات أسطوانية مقاس 6-8 مم عن طريق البثق بدرجة حرارة عالية للمواد الخام المعالجة (المواد المسحوقة مع محتوى الرطوبة داخل 20%). تم تجهيز عملية التكوير Jinwu بصوامع المواد الخام, الناقلات اللولبية المتداولة, وغيرها من المعدات الداعمة, تعمل بطريقة مغلقة بالكامل طوال العملية. وهذا يضمن الاستخدام الفعال للمواد الخام ويتجنب مشاكل التلوث بالغبار.

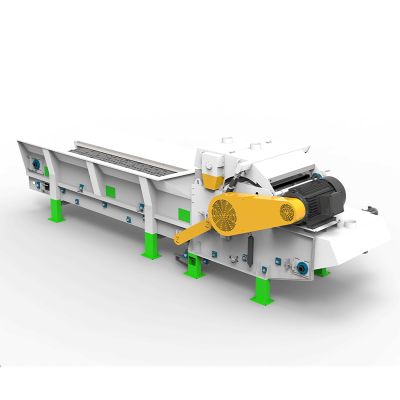

تحتوي الكسارة الشاملة للكتلة الحيوية على مجموعة واسعة من المواد الخام للمعالجة, ويمكن معالجة الخشب, مثل مختلف المواد ذات القطر الصغير, جلد لوحة, الشرائح, النوى السجل, إلخ., فضلا عن مختلف المواد الخام غير الخشبية مثل القش, الحطب القطن, القصب, إلخ., مع مجموعة واسعة من التطبيقات.

المطحنة المطرقية متعددة الوظائف للكتلة الحيوية هي المطحنة الأكثر استخدامًا على نطاق واسع والتي تتميز بقدرة عالية على توليد كيلووات/ساعة من الكهرباء وتعدد الاستخدامات.. يتم قطع المواد الخام الخشبية الصغيرة بشكل رئيسي من خلال القص عالي السرعة والطرق. مدفوعة بتدفق هواء قوي, ويتم الحصول على المسحوق المطلوب من خلال الشاشة, ويحدد حجم فتحة الشاشة حجم التفريغ.