احترافي

50+ خبرة سنوات

ضمان

3 ضمان سنوات

خدمة

الدعم الفني 7*12H

قطع غيار

المعيار والموحدة

المعلمات الفنية تفاصيل

| Moder No. | JWZL-420 | JWZL-688 | JWZL-688D | JWZL-800 | JWZL-860 | JWZL-998 |

|---|---|---|---|---|---|---|

| Main engine power | 90كيلوواط | 200KW-10P(optional servo permanent magnet motor) | 200KW-10P(optional servo permanent magnet motor) | 250KW-8P | 280KW-4P | 400KW-8P |

| Winch reducer | BWD2-59-YVF3-M1 | BWD2-59-YVF3-M1 | BWD2-59-YVF3-M1 | BWD2-43-Y3-4P | BWD4-59-Y4-4P | BWD4-59-Y4-4P |

| Force-feed motor | NMRV075-7.5-2.2-B14 | NMRV075-7.5-2.2-B14 | NMRV075-7.5-2.2-B14 | 2.2كيلوواط | 2.2كيلوواط | 3KW-6P |

| Cooling oil pump | CB-BL32-1.5KW | CB-BL32-1.5KW | CB-BL32-1.5KW | 1.5كيلوواط | 1.5كيلوواط | 1.5كيلوواط |

| heat exchanger | Water-cooled GLC-6 | Water-cooled GLC-6 | Water-cooled GLC-6 | Plate HU50-40-3.0-H | Plate HU50-40-3.0-H | Plate HU50-40-3.0-H |

| Reduction box | WJ-420 | WJ-688 | WJ-688 | WJ-800 | WJ-860 | WJ-998 |

| Gear oil | L-CKC220 | L-CKC220 | L-CKC220 | L-CKC220 | L-CKC220 | L-CKC220 |

| Ring mold | 420*91مم | 688*110/130مم | 688*110/130مم | 800*120مم | 860*120مم | 998*145مم |

| Compression roll | 260*206mm*2 | 303*116/136mm*2 | 303*116/136mm*2 | 380*126mm*2 | 400*126mm*2 | 480*151mm*2 |

| Equpment capacity | 1-1.5ذ | 2.2-3ذ | 2.5-3.2ذ | 3-4ذ | 4-5ذ | 6-8ذ |

| البعد الشامل | 2900*1320*2300مم | 3530*1580*2390مم | 3500*1500*2400مم | 3912*1500*2703مم | 3916*2084*2847مم | 5080*1965*3460 |

| وزن | 3.5T | 11T | 12.5T | 18T | ||

| Particle formation rate | ≥97% | ≥97% | ≥97% | ≥97% | ≥97% | ≥97% |

| Particle pulverization rate | ≤3% | ≤3% | ≤3% | ≤3% | ≤3% | ≤3% |

| {dB(أ)}System noise | ≤93 | ≤93 | ≤93 | ≤93 | ≤93 | ≤93 |

فيديو يوتيوب

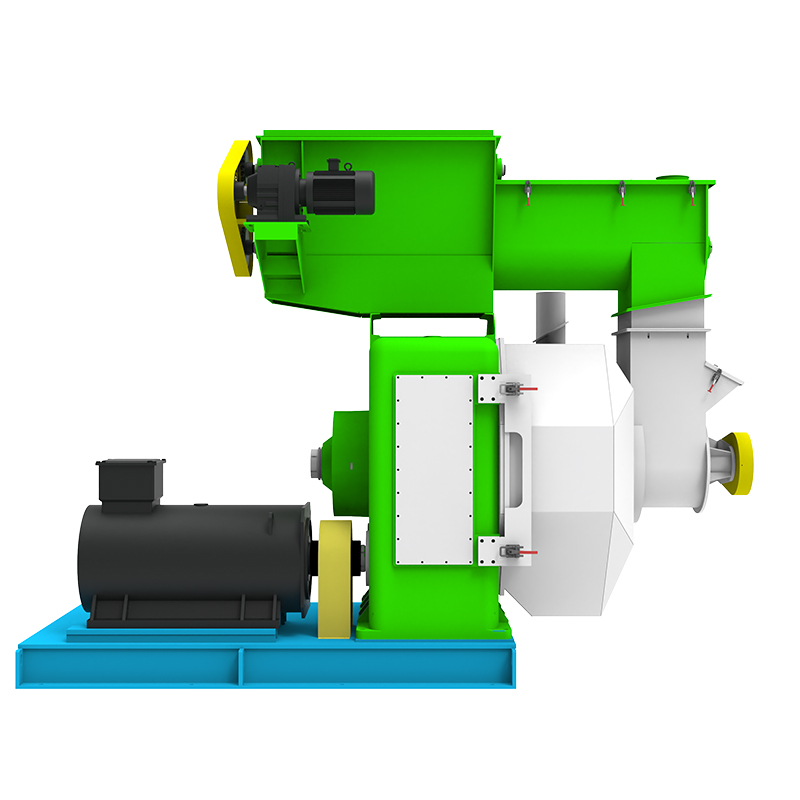

Biomass pellet machine is the core equipment in the biomass curing molding production line,and it is the granulation equipment of biomass pellet production.The process of particle production is mainly to make the treated raw materials (20% water crushing material) through high temperature extrusion into 6-8mm columnar particles, the section is general equipped with raw material silo, circular winch conveyor and other supporting equipment, the whole process of closed operation, efficient use of raw materials, there will be no dust pollution problems.

- The product adopts self-developed high precision, high strength hard tooth surface gear transmission box, the mechanism is reliable and durable, under different conditions of biomass pelleting, improve the use of equipment safety factor.

- Core components such as spindle and empty shaft are forged with high-quality alloy steel to improve the mechanical properties of equipment structural parts.

- The core transmission adopts high-quality bearings, and the transmission seal adopts wear-resistant fluorine rubber oil seal.

- The roller bearing adopts labyrinth mechanical seal, durable, effectively blocks the pollution of lubricating oi, and increases the service life of the bearing.

- Non-stop refueling system, water cooling system, كفاءة عالية, low energy consumption, long-term stable operation, reliable grain quality.

مزيد من المعلومات

المنتجات ذات الصلة

آلات قوية & الحلول

تجعلك أكثر نجاحًا

آلة بيليه الكتلة الحيوية

آلة بيليه الكتلة الحيوية

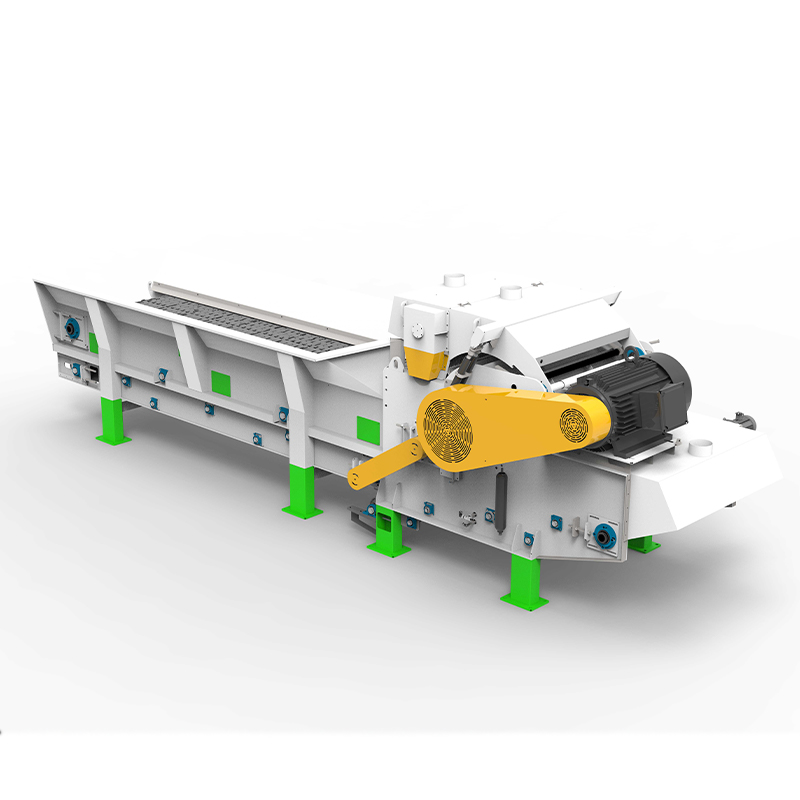

كسارة الكتلة الحيوية الشاملة

كسارة الكتلة الحيوية الشاملة

الطاحن الكتلة الحيوية

الطاحن الكتلة الحيوية

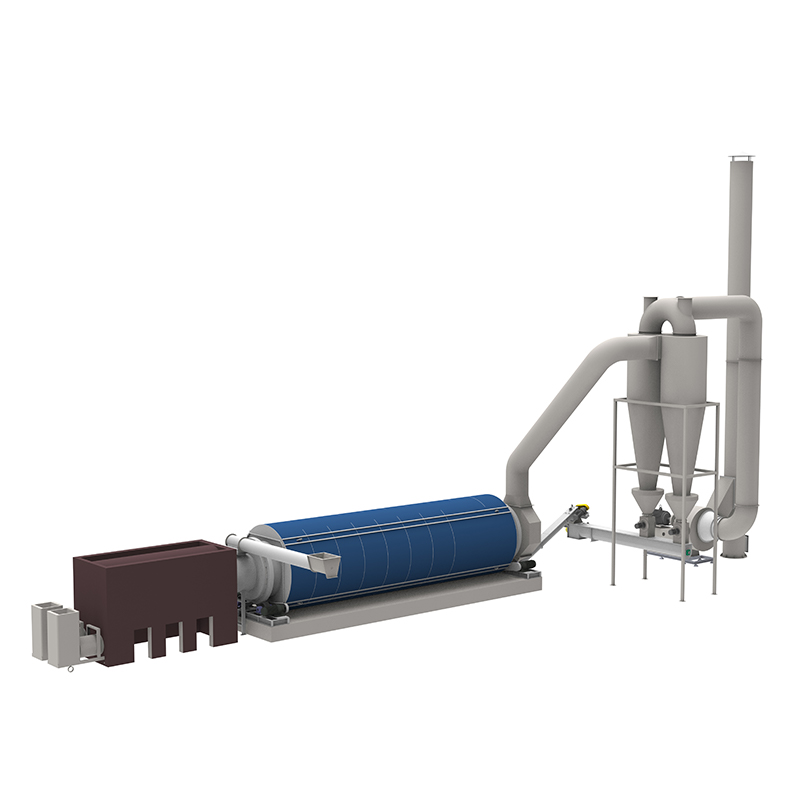

مجفف

مجفف