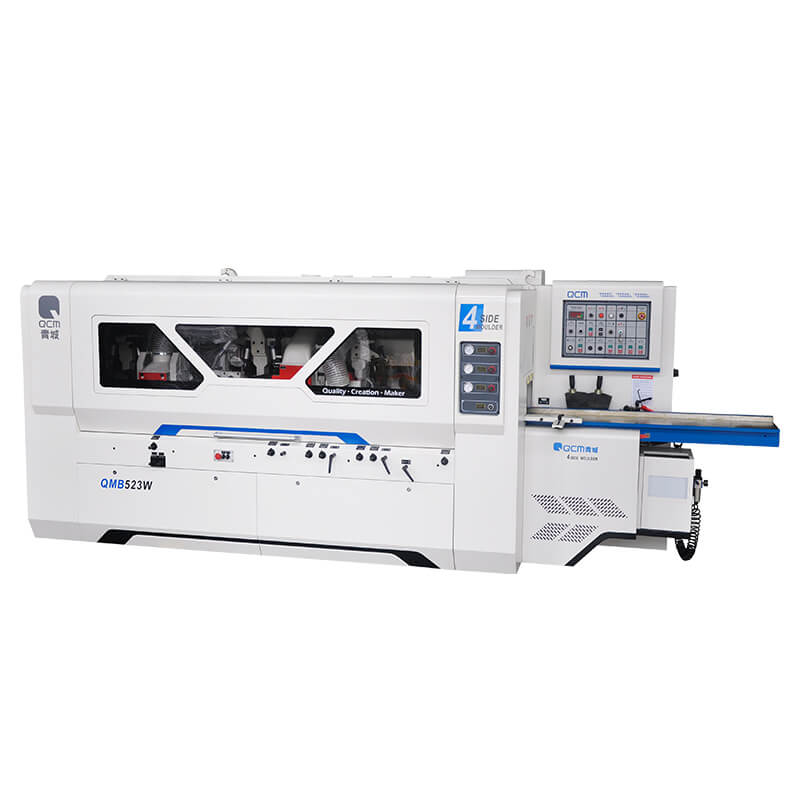

Nombre del producto: carpintería de madera de cuatro laterales

Modelo No.: QMB823GH

Ancho de trabajo: 20-230mm

Espesor de trabajo: 10-160mm

Husates: 8

Velocidad de alimentación: 10-60m/mi

Solicitud: 4 moldeadora y cepilladora lateral, Corte pesado para vigas grandes de madera, casa de madera, aserradero, Fábrica de muebles, etc. Curring de madera de madera de madera espesor de espesor de madera

50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMB623GH | QMB723GH | QMB823GH | |

|---|---|---|---|---|

| Ancho de trabajo | mm | 20-230 | 20-230 | 20-230 |

| Espesor de trabajo | mm | 10-160 | 10-160 | 10-160 |

| Mínimo. longitud de trabajo(intermitente/continuo) | mm | 720/280 | 720/380 | 720/280 |

| Es. de huso | mm | Φ50 | Φ50 | Φ50 |

| Es. de rodillo de alimentación | mm | Φ140 | Φ140 | Φ140 |

| Velocidad de alimentación | m/mi | 10-60 | 6-60 | 10-60 |

| Velocidad de rotación del huso | r/min | 7000 | 7000 | 7000 |

| Potencia total | KW/HP | 68.37/91 | 106.22/141 | 91.09/123.5 |

| Dié de campana de succión. | mm | 6*Φ180 | 7*Φ180 | 8*Φ180 |

| Dimensiones generales | mm | 5660*2100*1900 | 5660*2100*1900 | 6580*2080*1960 |

| Peso | kg | 8300 | 8800 | 10800 |

QMB823GH Four Side Moulder es una carpintería de cuatro lados de alta velocidad de alta velocidad. Para satisfacer las necesidades de a gran escala, a gran escala, y producción de alta eficiencia de clientes de procesamiento de madera maciza a gran escala.

TSu producto realiza la alimentación y corte de alta velocidad de productos de madera y adopta una tecnología de afilado de vanguardia en línea avanzada para afilar automáticamente los cuchillos traseros hacia arriba y hacia abajo., y los cuchillos verticales traseros izquierdo y derecho.

El ancho de procesamiento máximo es de 230 mm, y la velocidad de alimentación máxima es de 60 m/min.

La calidad de la superficie de la placa de procesamiento es buena y la eficiencia es alta.

Se usa ampliamente en fábricas de tablas de unión a gran escala y plantas de procesamiento de madera maciza a gran escala para alta eficiencia y producción en masa.

Es un equipo ideal para fábricas de muebles de madera maciza a gran escala y fábricas de tablas de unión a gran escala para reducir la cantidad de personas utilizadas para la producción y procesamiento., y es seguro y eficiente.

El cuerpo de la máquina está hecho de fundiciones de alta calidad, procesado por mecanizado de precisión, con rendimiento estable y buena rigidez.

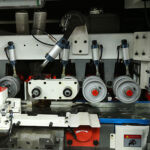

El diámetro del huso φ50 mm, Después del ensamblaje de precisión, Tratamiento de equilibrio dinámico, corriendo suave, buena rigidez, buena precisión.

La mesa de trabajo móvil está equipada con 2 conjuntos de rodillos de transmisión flotante neumática, lo que hace que la alimentación estable y potente.

El nivel superior trasero, el segundo y tercer cortador inferior están equipados con unir recto automático (mecanismo de afilado ) Para lograr un afilado automático de la cuchilla para satisfacer las necesidades del procesamiento de alimentación de alta velocidad.

Todos los cortadores horizontales están equipados con una estructura de soporte externo hidráulico, Uso de pistola de aceite de alta presión para aplicar presión al soporte externo para garantizar un rendimiento de corte de alta velocidad.

El rodillo de presión lateral del huso vertical izquierdo, La estructura del interruptor de la chip y la placa de presión delantera del cuchillo superior están equipadas con presión de cilindro para garantizar la alimentación de material liso.

El cortador superior delantero y trasero adopta el levantamiento sincrónico eléctrico, También se puede ajustar manualmente, Operación conveniente y rápida.

Los electrodomésticos adoptan la marca Siemens, Interfaz HMI Human-Machine, Operación conveniente y rápida.

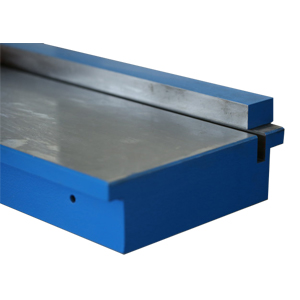

mesa en alimentación

La mesa de alimentación de nuestro 4 Player de cepillador lateral se puede alargar, Longitud personalizada de acuerdo con sus requisitos.

Potencia del motor

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

en & Fuera de alimentación

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

cuerpo de la máquina de fundición

4 El cepillador de lados tiene un cuerpo de máquina de hierro de fundición de una pieza extra pesado. Se trata especialmente térmicamente para la máxima estabilidad y rigidez por configuración estándar.

Siemens Electrical

Nuestro 4 Los moldores de cementerios del lado usan Siemens y Schneider Electrical Electrical Products and Appliances asegura que toda la máquina funcione bien con un rendimiento adecuado

cilindro Airtac

La presión neumática de los rodillos de alimentación se puede establecer fácilmente para proporcionar un efecto de alimentación sobresaliente para nuestro 4 cepillador de lados.

Recinto de seguridad

El recinto de seguridad con aislamiento de acero de acero pesado completo sirve como protector de chips y ayuda 4 Player de cepillador de lados para reducir el ruido y tiene iluminación estroboscópica.

alta precisión

Todos los husos son de precisión construidos y especialmente tratados con calor para proporcionar 4 Plantador lado Moulder Máxima estabilidad de corte y precisión permanente.

caja de cambios de servicio pesado

Los rodillos de alimentación de la cepilladora se conducen a través de una combinación de ejes universales y caja de cambios extra pesados, Asegúrese de que no hay pérdida de transmisión de energía. Se asegura un efecto de alimentación suave.

Excelente alimentación

Nuestro 4 La cepilladora de carpintería tiene más rodillos de potencia superior e inferior que la mayoría de los cuatro lidera de la competencia. Y esta es una razón importante para un rendimiento de alimentación sobresaliente.

escuchado crujido

Toda la mesa de alimentación cromada de hierro fundido se trata térmicamente para la máxima estabilidad. Mesa de alimentación & ajuste de la valla de 4 El moldeador lateral se logra rápidamente mediante las palancas rápidas.