50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMB418E-GH | QMB418E-T | QMB4018D-GH | |

|---|---|---|---|---|

| Ancho de trabajo | mm | 20-180 | 20-180 | 20-180 |

| Espesor de trabajo | mm | 8-110 | 8-100 | 8-100 |

| Mínimo. longitud de trabajo(intermitente/continuo) | mm | 500/250 | 530/300 | 500/200 |

| Es. de huso | mm | Φ40 | Φ40 | Φ40 |

| Velocidad de alimentación | m/mi | 10-45 | 8-33 | 10-45 |

| First spindle speed | r/min | 6800 | 6800 | 8000 |

| Other spindle speed | r/min | 6800 | 8000 | 8000 |

| Potencia total | KW/HP | 26.25/35 | 21.25/29 | 30.85/42 |

| Dié de campana de succión. | mm | 4*φ120 | 4*φ120 | 5*φ120 |

| Dimensiones generales | mm | 2930*1480*1600 | 3040*1600*1680 | 2900*1500*1600 |

| Peso | kg | 2750 | 2600 | 2950 |

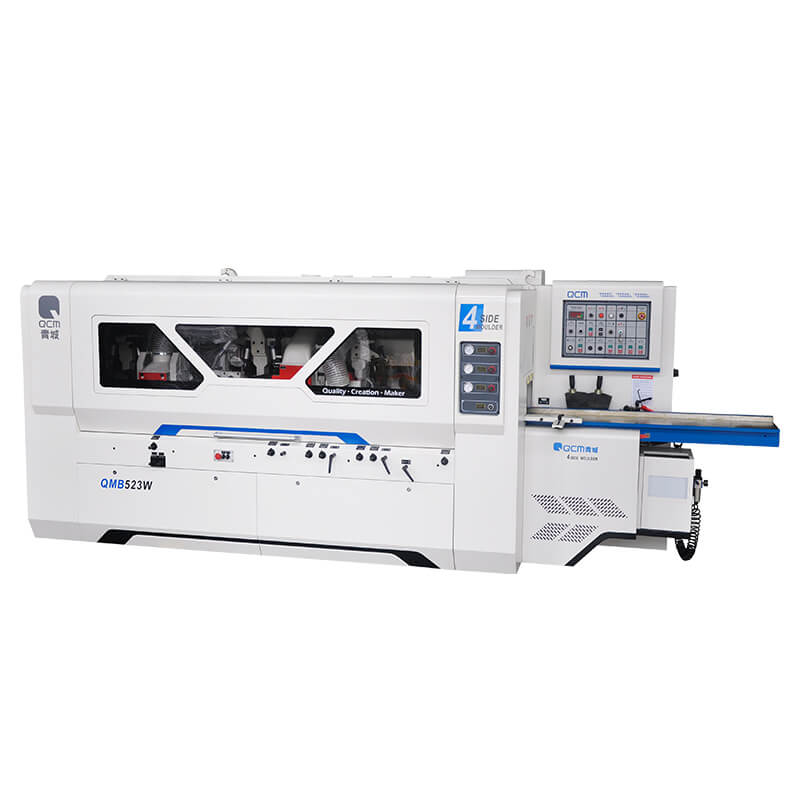

QMB418ET, QMB418E-GH and QMB4018D-GH, are economical planer moulder with maximum working width is 180mm, maximum working thickness is 110mm.

Four sided planer moulder for narrow and small wood, such as QMB412D, QMB412D-GH, QMB418ET, QMB418E-GH, QMB4018D-GH, QMB516ET, QMB616FT, is perfect solution for finger joint, such rubber wood finger board factory. We exported a lot to Vietnam, Indonesia, Malysia, Thailand, and other Southeast Asia.

The working width is from 120-180mm, working thickness is from 8-110mm. You can select planer moulder with enclosure, or without enclosure which is economic type. And you can select normal speed for 8-33m/min, or high speed 10-45m/min.

QMB418 type four sided planer moulder is professional solutions for finger joint board, wood profile profiling, 4 side planning for wooden flooring, wood line or moldings, tablas de madera, solid wood furniture, y planificación de cuatro lados.

planer moulder for narrow and small wood is mainly used in finger joint board factory, such as rubber wood finger joint board factory.

It can help you to make full use of wood material, no any waste.

- The four sided planer machine adopts the whole casting body, its performance, precision and stability, buena rigidez;

- Fully enclosed safety shield and open door power-off protection, low working noise, safety and environmental protection;

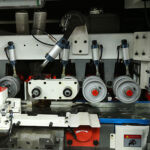

- The spindle is precisely processed, dynamically balanced and precisely assembled, with smooth operation and good precision;

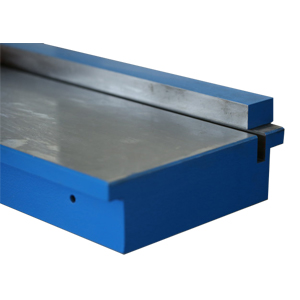

- The working table is made of special materials and special heat treatment, hard chrome plated, wear-resistant;

- The feeding system has three cylinder presses in the front, middle and back, with stable pressure and easy adjustment;

mesa en alimentación

The in-feeding table of our four sided planer moulder can be lengthened, Longitud personalizada de acuerdo con sus requisitos.

Potencia del motor

In our technical parameter table of four sided planer moulder you can see our standard configuration. Si lo necesitas, Podemos actualizar la energía del motor para usted.

en & Fuera de alimentación

Para ahorrar el costo laboral y mejorar la productividad para usted, we can combine four sided planer moulder for you with in-feeding and out-feeding system.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

cuerpo de la máquina de fundición

four sided planer has extra heavy one-piece casting iron machine body. Se trata especialmente térmicamente para la máxima estabilidad y rigidez por configuración estándar.

Siemens Electrical

Our four sided planer moulder use Siemens and Schneider electrical products and appliances insure the whole machine run well with a suitable performance.

cilindro Airtac

Pneumatic pressure of the feed rollers can be easily setted to provide an outstanding feeding effect for our four sided planer moulder.

Recinto de seguridad

The full heavy gauge steel sound insulated safety enclosure serves as a chip guard and helps four sided planer moulder to reduce noise and has strobe free lighting.

alta precisión

All spindles are precision constructed and specially heat treated to provide four sided planer moulder maximum cutting stability and permanent accuracy.

caja de cambios de servicio pesado

The feed rollers of four sided planer are driven through a combination of extra heavy universal shafts and gearbox, Asegúrese de que no hay pérdida de transmisión de energía. Se asegura un efecto de alimentación suave.

Excelente alimentación

Our four sided planer moulder has more top and bottom powered rollers than most competitor’s four side moulder. Y esta es una razón importante para un rendimiento de alimentación sobresaliente.

escuchado crujido

Toda la mesa de alimentación cromada de hierro fundido se trata térmicamente para la máxima estabilidad. Mesa de alimentación & El ajuste de la cerca de moldeador de cuatro lados se logra rápidamente mediante unas palancas rápidas.