50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMB620GH | QMB520GH | |

|---|---|---|---|

| Ancho de trabajo | mm | 20-200 | 20-200 |

| Espesor de trabajo | mm | 8-125 | 8-125 |

| Mínimo. longitud de trabajo(intermitente/continuo) | mm | 590/150 | 590/150 |

| Es. de huso | mm | Φ40 | Φ40 |

| Es. de rodillo de alimentación | mm | Φ140 | Φ140 |

| Velocidad de alimentación | m/mi | 10-60 | 10-60 |

| Velocidad de rotación del huso | r/min | 8000 | 8000 |

| Potencia total | KW/HP | 46.35/62 | 42.6/57 |

| Dié de campana de succión. | mm | 6*φ120 | 5*φ120 |

| Dimensiones generales | mm | 4180*1780*1780 | 3630*1790*1760 |

| Peso | kg | 5100 | 4300 |

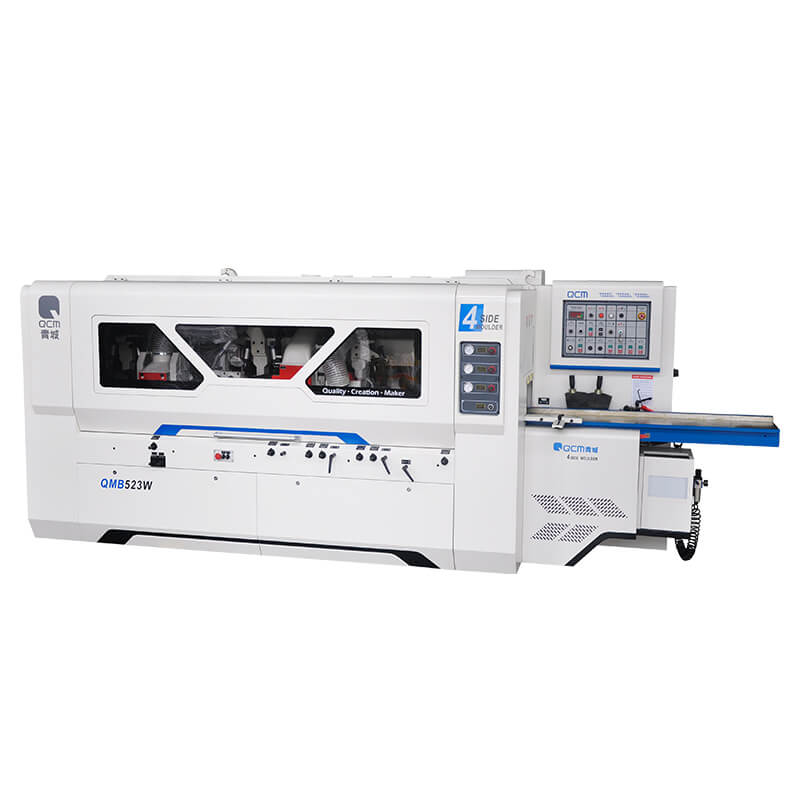

QMB520GH, QMB620GH high speed 4 sided moulder planer machine are perfect solution for mass production of timber or finger joint board manufacturer, maximum working width 200mm.

A lot of finger joint board manufacturer combine QMB620GH 4 sided moulder, and other finger jointing machines together to make an automatic production line, which can save a lot of labor cost, and get much higher productivity.

As a professional 4 sided moulder planer manufacturer, we have 5 spindles, 6 spindles high speed 4 side moulder. They are equipped with a centrifugal feeder or a vertical and horizontal feeder connection to realize automatic feeding four-sided planing processing. In particular, the intermediate worktable of this product adopts a groove positioning and guiding structure, which can overcome the occurrence of material running and jams in the processing of ordinary four-sided planing short materials.

El ancho máximo de procesamiento es de 200 mm., the maximum processing thickness is 125mm, the shortest processing length is 150mm (continuous), and the feeding speed is 10-60m/min. It has the advantages of high production efficiency and good processing quality. It is the ideal equipment for upgrading and upgrading of the vast solid wood processing finger-joint panel industry.

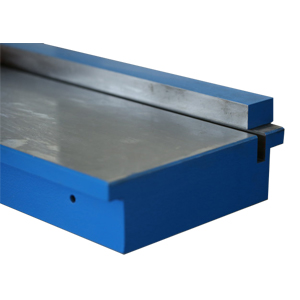

- The middle worktable adopts a groove positioning structure. After special heat treatment and hard chrome plating, it can reduce the heat of the worktable and ensure the smooth feeding when the shortest processing length is 150mm.

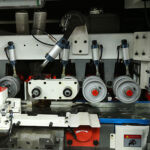

- The movable worktable adopts a cylinder floating active feeding roller structure, which improves the smoothness of the feeding of bent and deformed materials, and realizes high-speed and strong feeding.

- The feeding system is equipped with a high-speed worm gear reducer, universal coupling transmission and imported frequency converter, which realizes variable frequency speed regulation, and the feeding speed can reach 10-60 m/mi. Its performance is stable, and the operation is convenient and quick.

- The CLSJ900 side chain conveyor is standard on the outside of the movable table of the main machine to ensure the smoothness of high-speed feeding.

mesa en alimentación

La mesa de alimentación de nuestro 4 sided moulder can be lengthened, Longitud personalizada de acuerdo con sus requisitos.

Potencia del motor

In our technical parameter table of planer moulder, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

en & Fuera de alimentación

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

cuerpo de la máquina de fundición

4 El cepillador de lados tiene un cuerpo de máquina de hierro de fundición de una pieza extra pesado. Se trata especialmente térmicamente para la máxima estabilidad y rigidez por configuración estándar.

Siemens Electrical

Nuestro 4 Los moldores de cementerios del lado usan Siemens y Schneider Electrical Electrical Products and Appliances asegura que toda la máquina funcione bien con un rendimiento adecuado

cilindro Airtac

La presión neumática de los rodillos de alimentación se puede establecer fácilmente para proporcionar un efecto de alimentación sobresaliente para nuestro 4 cepillador de lados.

Recinto de seguridad

El recinto de seguridad con aislamiento de acero de acero pesado completo sirve como protector de chips y ayuda 4 Player de cepillador de lados para reducir el ruido y tiene iluminación estroboscópica.

alta precisión

Todos los husos son de precisión construidos y especialmente tratados con calor para proporcionar 4 sided moulder maximum cutting stability and permanent accuracy.

caja de cambios de servicio pesado

The feed rollers of 4 sided planer are driven through a combination of extra heavy universal shafts and gearbox, Asegúrese de que no hay pérdida de transmisión de energía. Se asegura un efecto de alimentación suave.

Excelente alimentación

Our planer moulder has more top and bottom powered rollers than most competitor’s four side moulder. Y esta es una razón importante para un rendimiento de alimentación sobresaliente.

escuchado crujido

Toda la mesa de alimentación cromada de hierro fundido se trata térmicamente para la máxima estabilidad. Mesa de alimentación & ajuste de la valla de 4 El moldeador lateral se logra rápidamente mediante las palancas rápidas.