50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | MS3113B | |

|---|---|---|

| Máximo. length of mortise | mm | 130 |

| Máximo. depth of mortise | mm | 60 |

| Máximo. width of mortise | mm | 16 |

| Velocidad del huso | r/min | 15200 |

| Potencia total | KW/HP | 2.2/3 |

| Hunting frequency | times/min | 170-230 |

| Air pressure | MPa | 0.4-0.6 |

| Dimensiones generales | mm | 1480*1150*1250 |

| Peso | kg | 550 |

1. The fuselage is made of high-quality steel plates welded and processed, and the performance is stable.

2. The spindle adopts high-precision heavy cutting structure, and the spindle speed reaches 15000r/min, with high efficiency.

3. The tenon and groove swinging mechanism adopts the structure of precision cylindrical guide rail sliding bearing, and is equipped with a hand pressure lubricating pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

4. The tongue and groove width adjustment adopts digital display, manual adjustment, simple operation and more accurate processing.

5. The adjustment of the spindle swing speed adopts the friction wheel tensioning speed adjustment structure to adjust the speed to meet the processing needs of various materials.

6. The tenon and groove operation adopts double worktables alternately, and the worktable can process the inclined tenon and groove at an inclined angle.

This product is mainly to meet the needs of tongue and groove processing of solid wood doors, tables and chairs.

This mortising machine is an economical and practical horizontal double-end slotting machine. The maximum tongue groove width is 130mm, the maximum groove depth is 60mm, and the maximum deep groove width is 16mm. The product has stable performance, simple operation, convenient maintenance and high cost performance. It is an economical and applicable equipment for groove processing in the solid wood processing industry.

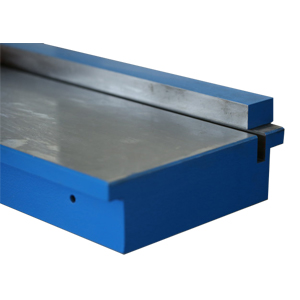

mesa personalizada

La mesa de alimentación de nuestro 4 Player de cepillador lateral se puede alargar, Longitud personalizada de acuerdo con sus requisitos.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

Sistema de transporte

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

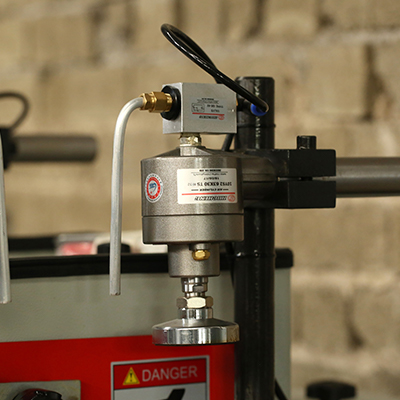

Eje de alta precisión

The spindle adopts a high-precision heavy-cutting structure, and the spindle speed reaches 15000r/min, which meets the needs of high efficiency in mortising processing.

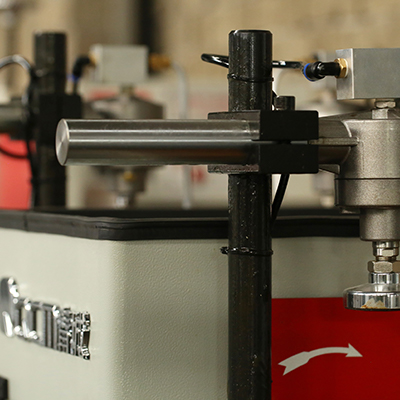

GUIDE RAIL

The mortising mechanism adopts a precision cylindrical guide rail sliding bearing structure, and is equipped with a hand pressure lubrication pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

CONVENIENT ADJUSTMENT

The width of the mortising adopts digital display, manual adjustment, simple operation, convenient adjustment and more accurate processing.

SPINDLE SPEED ADJUSTMENT

The adjustment of the spindle swing speed adopts the friction wheel tension adjustment speed structure to adjust the speed to meet the processing needs of various materials.

DOUBLE WORKBENCHES

The mortising operation adopts double workbenches to work alternately, and the workbench can be inclined to process the oblique mortise.