Nombre del producto: double-end tenoning machine, double-end tenoner MXK3812A

Solicitud: wooden furniture, table, chair

Functions: double-end milling square tenon, oblique tenon, round tenon, oval tenon.

Working Length: 250-1200mm

Ancho de trabajo: 10-115mm

Espesor de trabajo: 10-60mm

Máximo. Length of Tenon: 40(70mm optional)

50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | MXK3812A | MXK3821A | |

|---|---|---|---|

| Working lenght | mm | 250-1200 | 200-2100 |

| Ancho de trabajo | mm | 10-115 | 10-160 |

| Máximo. processing thickness of tenon | mm | 20 | 20 |

| Máximo. tenon lenght | mm | 40 | 40 |

| Milling tenon speed | r/min | 12000 | 12000 |

| Milling spindle dia. | mm | Φ30 | Φ30 |

| Potencia total | KW/HP | 11.4/15 | 13.2/18 |

| Dié de campana de succión. | mm | 2*φ100 | 4*φ100 |

| Dimensiones de la máquina | mm | 2650*1400*1700 | 2650*1400*1700 |

| Peso | kg | 1950 | 1950 |

1. The bed is cast as a whole with high-quality castings, con rendimiento estable y buena precisión;

2. The milling shaft adopts the frequency conversion motorized spindle, which is suitable for the processing of wood products of different materials and hardness;

3. The original swinging hinge feeding mechanism realizes fast feeding and low failure rate;

4. Using hopper feeding to realize automatic feeding;

5. The X-axis and Y-axis can be inclined at an angle, which can be used for inclined milling operations;

6. Equipped with automatic lubricator to ensure smooth operation;

7. Optional: It can be lengthened by 2200mm according to the requirements of the user’s bedroom furniture bed, the model is MXK3820A.

This machine is a CNC automatic double-end tenon milling machine. It is to meet the needs of the solid wood processing industry for safety, efficiency and reduction of labor. Especially in the dining table, dining chair, solid wood furniture industry, the demand for batch efficient processing. Two-axis linkage CNC double-end milling square tenon, oblique tenon, round tenon and ellipse tenon, It has the advantages of simple operation, conveniente y rápido, efficient processing and good quality. It is an ideal equipment for large-scale production, expansion of production capacity, and file upgrades in the solid wood furniture, dining table, and dining chair industries.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

Sistema de transporte

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

Hierro fundido entero

Extra pesada de una pieza, El marco de la máquina de hierro fundido es especialmente tratado térmicamente para obtener la máxima estabilidad y rigidez por configuración estándar.

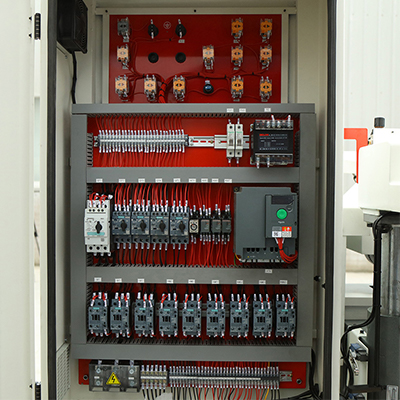

Siemens Electrical

Los productos y electrodomésticos de Siemens y Schneider aseguran que toda la máquina funcione bien con un rendimiento estable

SYNCHRONOUS MOVEMENT

Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

ADVANCED PLC CONTROL

The operating system is equipped with an imported computer touch screen and PLC for joint control, which is intuitive and convenient to operate, which can effectively reduce adjustment time and improve production efficiency.