Nombre del producto: double-end tenoning machine, double-end tenoner QMX8025M

Solicitud: door making, piso de madera, for wooden furniture production and interior furnishings

Functions: squaring, trimming, rabbeting, perfilando, grooving

Ancho de trabajo: 300-2500mm

Espesor de trabajo: 10-120mm

Velocidad de alimentación: 6-36m/mi

Husates: 8 Husates

50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMX8025M | QMX6025M | QMX3826D*8 | QMX3820D | |

|---|---|---|---|---|---|

| Ancho de trabajo | mm | 300-2500 | 300-2500 | 300-2600 | 300-2000 |

| Espesor de trabajo | mm | 10-120 | 10-120 | 10-70 | 10-70 |

| Feeding block spacing | mm | 500 | 500 | 240 | 240 |

| Velocidad de alimentación | m/mi | 6-36 | 6-36 | 5-20 | 5-20 |

| Saw shaft speed | r/min | 3000 | 3000 | 3000 | 3000 |

| Milling axis speed | r/min | 7500 | 7500 | 7000 | 7000 |

| Buckle milling spindle speed | r/min | / | / | 8000 | / |

| Potencia total del motor | KW/HP | 47/64 | 41/56 | 26.06/35 | 20.95/28 |

| Vacuum port diameter | mm | 8*φ120 | 6*φ120 | 8*φ100 | 6*φ100 |

| Dimensiones de la máquina | mm | 4880*4650*1900 | 4880*4130*1890 | 4700*3350*1600 | 4100*2500*1460 |

| Peso | kg | 6500 | 6000 | 4300 | 3250 |

This high-performance double-end tenoner can be configured as required to tackle a host of different tasks: angle cuts, bevel cuts, perfilando, rabbeting, grooving, sanding and corner processing. Thanks to its robust design, low-wear technology and high level of availability, this double end tenoning machine machine is exactly the right choice for manufacturing doors, fronts and panels.

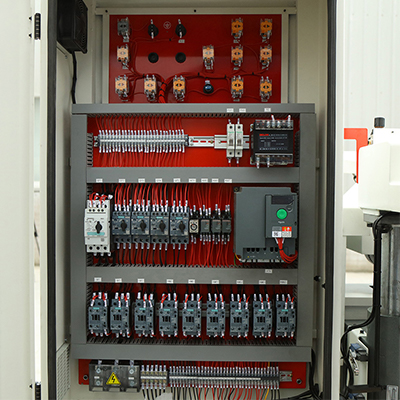

• User-friendly PLC control

• Width setting through touch-sensing screen for increased accuracy and convenience

• Moulding spindle is directly driven by a high-frequency motor, providing 7,500 rpm spindle speed

• Link chains are driven by a frequency-inverted motor, ensuring synchronized feed at both sides

• 6 y 8 spindles (optional)

Double end tenoner provides the best way to productivity and versatility

• The double end tenoner is designed and engineered for high quality wooden furniture with profitable production.

• They are ideal for producing solid wood and panel furniture and wooden doors.

• The series of double end tenoner provides various functions, such as double end sizing, profile moulding. It’s a highly automated machine that creates the efficiency you’ve come to expect.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

Sistema de transporte

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

Hierro fundido entero

Extra pesada de una pieza, El marco de la máquina de hierro fundido es especialmente tratado térmicamente para obtener la máxima estabilidad y rigidez por configuración estándar.

Siemens Electrical

Los productos y electrodomésticos de Siemens y Schneider aseguran que toda la máquina funcione bien con un rendimiento estable

GUIDE RAIL

Feeding guide rail is cast with sectional combination structure. 1300mm long feeding area has a feature of easy assembling, stable precision, especially suitable for large size work piece.

SYNCHRONOUS MOVEMENT

Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

SCORING + HOGGER UNIT

Up pressing mechanism is configured with NC electric lift, ensuring the stable pressing and more convenient and quick operating.

ADVANCED PLC CONTROL

The operating system is equipped with an imported computer touch screen and PLC for joint control, which is intuitive and convenient to operate, which can effectively reduce adjustment time and improve production efficiency.