اسم المنتج: Planing and sanding machine SPR-RP1300

طلب: Planing and sanding for finger joint board with glue

عرض العمل: 40-1300مم

سمك العمل: 3-120مم

Sanding belt: 3

سرعة التغذية: 6-30م/بلدي

50+ خبرة سنوات

3 ضمان سنوات

الدعم الفني 7*12H

المعيار والموحدة

| تحديد | SPR-RP1300 | SRRP1300C | SRP1300B | SRP630S | |

|---|---|---|---|---|---|

| Sanding cutting width | مم | 40-1300 | 40-1300 | 40-1300 | 40-630 |

| Sanding cutting thickness | مم | 3-120 | 3-120 | 3-160 | 3-180 |

| The shortest sand cutting length | مم | 520 | 500 | 620 | 230 |

| Planer shaft speed | m/s | 36 | / | / | / |

| Speed of the first group of sanding belt | m/s | 19 | 21 | 19 | 19 |

| Speed of the first group of sanding belt | m/s | 18.5 | 19 | 18 | 16 |

| Speed of the third group of sanding belt | m/s | / | 18.5 | / | / |

| سرعة التغذية | م/بلدي | 6-30 | 6-30 | 6-30 | 6-30 |

| Sanding belt size | مم | 1330*2200 | 1330*2200 | 1330*2200 | 650*2100 |

| Total motor power | KW/HP | 77.12/103 | 95.62/128 | 57.12/77 | 20.74/28 |

| Vacuum port of dia. | مم | 9*Φ150 | 7*Φ150 | 5*Φ150 | 5*Φ150 |

| Machine dimensions | مم | 2850*2050*2200 | 2800*2040*2200 | 2260*2060*2230 | 2120*1270*2050 |

| Machine weight | كجم | 5150 | 5050 | 3700 | 1900 |

According to the needs of the majority of solid wood square processing users and finger-joined board industry processing users to improve efficiency, reduce the number of processes, reduce costs, based on the three wide belt sander to improve the development of planing and sanding machine series.

The main solution is to clean up the glue on the back of the finger-joined board and to fix the thickness of the planing and sanding work. It has the advantages of low power of planing motor, low production consumption and high cost performance. Mainly used for solid wood finger-joined board, solid wood finger-joined square material planing and fine sanding. It is the ideal equipment for high efficiency, high quality and low cost production in the solid wood furniture manufacturing industry and solid wood finger-joined board industry.

1. The beam support of planing and sanding machine adopts high-quality castings, which has good shock absorption, stable performance and good precision.

2. This planing and sanding machine integrates a precision spiral planer shaft, a fixed thickness rubber roller and a combined fine polishing roller. It adopts first planing and then sanding, which has the advantages of energy saving and high efficiency, and good quality of sanding surface.

3. The first sand frame is a precision spiral planer assembly. It adopts a Φ180 cutting circle and 8-blade imported planer roller, equipped with 15*15*2.5mm imported Luxembourg discarded carbide blades, which is easy to use and good in planing quality.

4. The second sand frame is a Φ240 large diameter fixed thickness rubber roller, and the third sand frame is a Φ210 fine sand rubber roller with a polishing structure. Good quality of sanding surface.

5. In order to ensure the safety of the planing and sanding machine, the machine is equipped with 2 groups at the front, 1 group in the middle, و 1 group at the rear, a total of 5 groups of idler roller structures, and a non-reverse claw safety protection device is arranged in front of the planer chip breaker to prevent the workpiece from rebounding during planing. , To ensure safer operation.

6. The front of the planing roller part is equipped with a piano-key segmented pressing claw structure, and the rear is equipped with a flat pressing plate structure, which can effectively meet the simultaneous feeding and planing of multiple workpieces, greatly improving production efficiency.

7. Imported photoelectric control system is used to control the belt swing, equipped with photoelectric switch and photoelectric board, it runs smoothly, detects accurately, and controls sensitively.

8. The upper part of the first idler roller is equipped with a feeding limit thickness protection device to protect the planer shaft over thickness to ensure safer and more reliable equipment operation.

9. The feeding adopts a heavy-duty helical gear-worm gear reducer and a frequency converter to realize variable-frequency and variable-speed feeding, and the feeding speed can reach 6-30m/min. Its operation is stable and the feeding is strong and powerful.

10. Optional configuration: According to the user’s needs for heavy cutting of unequal thickness wool, a 30*12 heavy cutting spiral planer roll is selected to meet the requirements of cutting performance and processing quality.

محرك مخصص

In our technical parameter table of sanding machine, يمكنك رؤية التكوين القياسي لدينا. إذا كنت بحاجة, يمكننا ترقية طاقة المحرك لك.

نظام الناقل

من أجل توفير تكلفة العمالة وتحسين الإنتاجية لك, we can combine sanding machines for you with automatic in-feeding and out-feeding system.

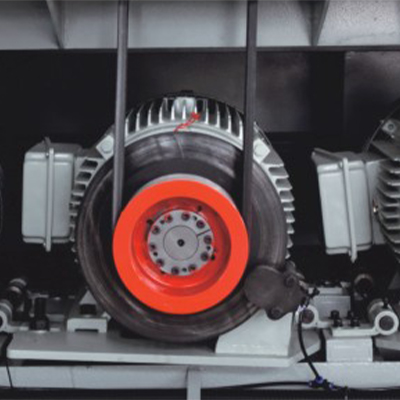

inside setted motors

Motors for coarse sanding, semi-fine sanding, fine sanding are inside setted , to make cleaning appearance.

anti-reversal roller

The second group of idler rollers is anti- reversal roller, to protect the safety of the operator.

casting plates

The support plates are made of high quality casting, which makes our machine more stable and high accuracy.

Double pressure roller

Double pressure roller structure to ensure seady and smooth feeding.

stablly and precisely

SPR-RP series configured with precision spiral planing cutter module, and in keyboard type sectional pressuring structure. It’s can plan and sanding at the same time, stablly and precisely.

8 sets feeding rollers

SRR630S type is equipped with 8 sets feeding rollers, 3 front, 2 in middle, 3 rear. So it can apply to materails over 230mm length.