50+ خبرة سنوات

3 ضمان سنوات

الدعم الفني 7*12H

المعيار والموحدة

| Specification | FJL150A | FJL150B | FJL1508A | FJL1508D | FJL1509E | |

|---|---|---|---|---|---|---|

| Infeed length | مم | 150-850 | 150-850 | 150-850 | 150-850 | 150-850 |

| Shaping thickness | مم | 450 | 20-150 | 20-150 | 20-150 | 20-150 |

| الأعلى. working width for shaper working table | مم | 450 | 590 | 590 | 590 | 590 |

| Pressing thickness | مم | 20-80 | 20-80 | 20-80 | 20-80 | 20-80 |

| Pressing width | مم | 30-150 | 30-150 | 30-150 | 30-150 | 30-150 |

| Shaper spindle diameter | مم | φ50 | φ50 | φ50 | φ50 | φ50 |

| Shaper spindle speed | ص/دقيقة | 5600 | 5600 | 5600 | 5600 | 5600 |

| Hogger spindle diameter | مم | f30 | f30 | f30 | f30 | f30 |

| Hogger spindle speed | ص/دقيقة | 2840 | 2840 | 2840 | 2840 | 2840 |

| الأعلى. pressing length | مم | 2500 | 2500 | 6040 | 6040 | 6040 |

| الأعلى. thrust force | كجم | 3000 | 3000 | 7500 | 7500 | 7500 |

| Total motor power | كيلوواط | 42.7 | 50.7 | 60.7 | 60.7 | 65.35 |

| Fixing dimensions | مم | 8000*6000 | 9300*6000 | 18900*6000 | 18900*6000 | 18000*6000 |

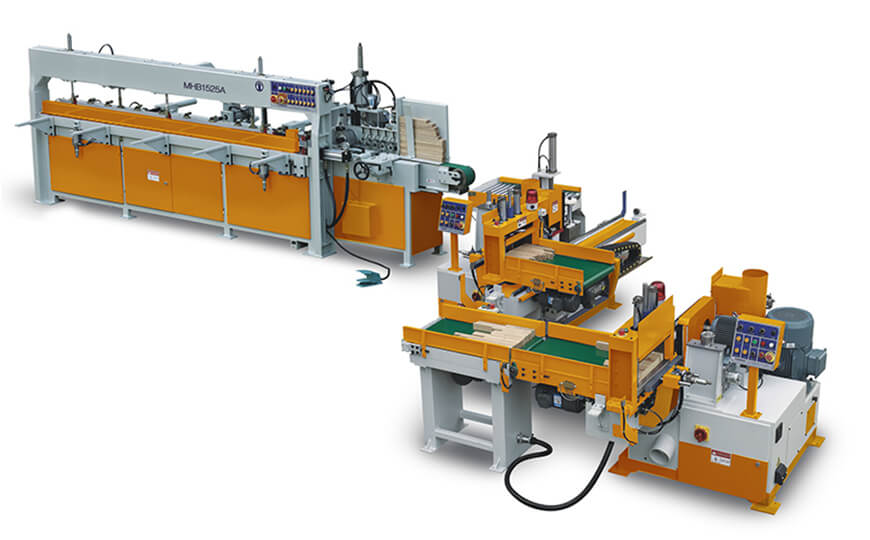

The finger joint line is composed of two finger joint shaper and one finger joint presser.Full automatic finger jointing line technology to complete the processes of finger shaping, glue application, conveying, jointing and pressing of wood pieces.

1. Belt Conveyor

double section in-feed table for continuous feeding and alignment of raw materials.

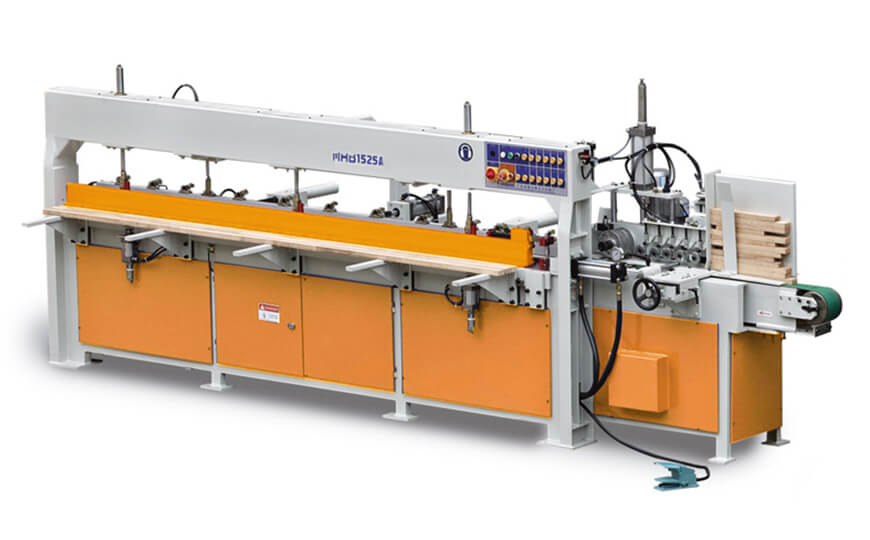

2. Fully Automatic Shaper

Perform trimming and shaping to one end of the wood pieces, with adjustable shaping depth and number of teeth. Upon completion, the wood pieces will be transferred automatically to the next operation process.

3. Fully Automatic Shaper (with glue device)

Receive wood pieces from previous process and perform trimming and shaping to the other end of the wood pieces. Glue will then be applied and the wood pieces will be transferred automatically to the next operation process.

4. Roller Conveyor

Guiding and conveying wood pieces from the previous process to the next operation process, at a preset speed.

5. Chain Conveyor

To line up the wood pieces from the previous process before flipping the pre-jointed wood pieces 90°. The pre-jointed wood pieces will be buffered before being conveyed to the next operation process.

6. Fully Automatic Composer

To compose the pre-jointed wood pieces into the finished product. Sectional compossing at different length is avialibale in this machine.

Using German electrical control element that quarantees operation efficiency, durability and stability.

With the use of encoder to detect the composed length of wood, the operation is more flexible and accurate.

With the use of Japanese micro-computer control system, the operation is simply user-friendly.

Complete with CE safety standard for controls, user friendly operation function, stable, reliable & safe to operate.

Through multiple technological innovations, the machine can be tailored to different requirement in raw material sizes, suitable for differentlevels of moisture content and hardness.

High precision link up of working process and multifaceted sensory feedback ensures stability in operation compared to traditional Finger Joint technology.

With the use of noise reduction technology, together with cushioning and sound proof design for vibrating parts, it keeps noise level to minimum and maximizes its stability and machine life span compared to traditional Finger Joint design.

Proper dust removal design that can be incorporated into either centralized or individual dust collection system that keeps the pollution by sawdust to minimum.