50+ خبرة سنوات

3 ضمان سنوات

الدعم الفني 7*12H

المعيار والموحدة

| تحديد | QMX8025M | QMX6025M | QMX3826D*8 | QMX3820D | |

|---|---|---|---|---|---|

| عرض العمل | مم | 300-2500 | 300-2500 | 300-2600 | 300-2000 |

| سمك العمل | مم | 10-120 | 10-120 | 10-70 | 10-70 |

| Feeding block spacing | مم | 500 | 500 | 240 | 240 |

| سرعة التغذية | م/بلدي | 6-36 | 6-36 | 5-20 | 5-20 |

| Saw shaft speed | ص/دقيقة | 3000 | 3000 | 3000 | 3000 |

| Milling axis speed | ص/دقيقة | 7500 | 7500 | 7000 | 7000 |

| Buckle milling spindle speed | ص/دقيقة | / | / | 8000 | / |

| Total motor power | KW/HP | 47/64 | 41/56 | 26.06/35 | 20.95/28 |

| Vacuum port diameter | مم | 8*f120 | 6*f120 | 8*φ100 | 6*φ100 |

| Machine dimensions | مم | 4880*4650*1900 | 4880*4130*1890 | 4700*3350*1600 | 4100*2500*1460 |

| وزن | كجم | 6500 | 6000 | 4300 | 3250 |

1. The machine body and its bed are integrally cast with high-quality castings, which are specially processed and precisely processed by the five-sided gantry machining center, مع أداء مستقر, good rigidity and high precision. .

2. The main shaft adopts special materials, after special treatment, precision processing and assembly, the speed of the milling cutter is 7000r/min and the speed of the buckle shaft is 8000r/min, which has the advantages of stable operation and good processing quality.

3. The feeding adopts high-precision synchronous track connection and round bar guide rail guide structure to ensure stable operation, accurate positioning and good processing quality.

4. The fixed width system adopts imported linear guide rail and ball screw drive, and is equipped with a fixed protective cover to overcome the previous phenomenon of wood chip dust blocking the guide rail and ensure the precise width of the fixed width system.

5. The workbench panel is made of special wear-resistant synthetic material, which runs smoothly, has good processing quality and greatly improves wear resistance.

6. The selected feeding system is equipped with a hard-tooth surface reducer and an imported frequency converter to realize variable-frequency feeding. The feeding speed can reach 5-20m/min. The operation is convenient and fast, and it is suitable for processing various materials.

7. The material pressing beam adopts double-column material pressing structure and electric lifting structure to ensure stable material pressing, guarantee the quality of processed products, and the operation is convenient and quick.

Mainly used for milling and tenoning processing of solid wood flooring, engineered flooring, and laminate flooring double-end trimming machine. It is the ideal equipment for upgrading and upgrading of the majority of users in the floor processing industry.

Double end tenoner QMX3826D and QMX3820D are mainly designed and developed according to the needs of floor processing in the solid wood flooring and engineered wood floor processing industries. The front is up and down sawing, the middle milling shaft, and the back is double-end milling product with a universal milling shaft. The maximum processing width is 2600mm and the maximum processing thickness is 70mm, which can effectively meet the processing of snap tenons that cannot be completed by the six-axis floor double-end milling tenon.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

أدوات القطع

لا تحتوي معظم آلات النجارة الخشبية على أدوات القطع عند التصدير, لأن مصانع النجارة المختلفة تحتاج إلى نوع مختلف من القواطع. لتحسين خدمتنا, يمكننا مساعدتك في شراء أدوات القطع.

محرك مخصص

في جدول المعلمات الفنية لدينا 4 سوي على الوجهين متلهف, يمكنك رؤية التكوين القياسي لدينا. إذا كنت بحاجة, يمكننا ترقية طاقة المحرك لك.

نظام الناقل

من أجل توفير تكلفة العمالة وتحسين الإنتاجية لك, يمكننا الجمع 4 تم تجهيز مستوي لكم مع نظام التغذية والتغذية الخارجية.

حديد الزهر بالكامل

قطعة واحدة ثقيلة جدًا, يتم معالجة إطار آلة الحديد الزهر بالحرارة خصيصًا لتحقيق أقصى قدر من الثبات والصلابة من خلال التكوين القياسي.

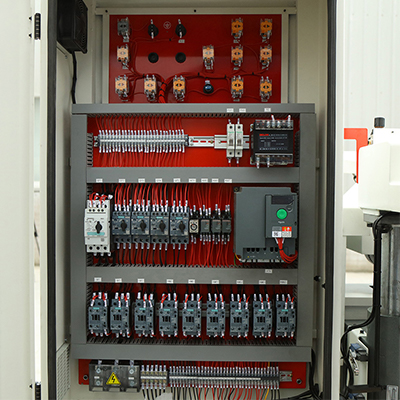

سيمنز الكهربائية

تضمن المنتجات والأجهزة الكهربائية Siemens وSchneider أن الآلة بأكملها تعمل بشكل جيد مع أداء مستقر

SYNCHRONOUS MOVEMENT

Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

ADVANCED PLC CONTROL

The operating system is equipped with an imported computer touch screen and PLC for joint control, وهو بديهي ومريح للعمل, which can effectively reduce adjustment time and improve production efficiency.