اسم المنتج: double-end tenoning machine, double-end tenoner QMX6025M

طلب: door making, wooden flooring, for wooden furniture production and interior furnishings

وظائف: squaring, trimming, rabbeting, التنميط, grooving

عرض العمل: 300-2500مم

سمك العمل: 10-120مم

سرعة التغذية: 6-36م/بلدي

مغزل: 6 مغزل

50+ خبرة سنوات

3 ضمان سنوات

الدعم الفني 7*12H

المعيار والموحدة

| تحديد | QMX8025M | QMX6025M | QMX3826D*8 | QMX3820D | |

|---|---|---|---|---|---|

| عرض العمل | مم | 300-2500 | 300-2500 | 300-2600 | 300-2000 |

| سمك العمل | مم | 10-120 | 10-120 | 10-70 | 10-70 |

| Feeding block spacing | مم | 500 | 500 | 240 | 240 |

| سرعة التغذية | م/بلدي | 6-36 | 6-36 | 5-20 | 5-20 |

| Saw shaft speed | ص/دقيقة | 3000 | 3000 | 3000 | 3000 |

| Milling axis speed | ص/دقيقة | 7500 | 7500 | 7000 | 7000 |

| Buckle milling spindle speed | ص/دقيقة | / | / | 8000 | / |

| Total motor power | KW/HP | 47/64 | 41/56 | 26.06/35 | 20.95/28 |

| Vacuum port diameter | مم | 8*f120 | 6*f120 | 8*φ100 | 6*φ100 |

| Machine dimensions | مم | 4880*4650*1900 | 4880*4130*1890 | 4700*3350*1600 | 4100*2500*1460 |

| وزن | كجم | 6500 | 6000 | 4300 | 3250 |

This high-performance double-end tenoner can be configured as required to tackle a host of different tasks: angle cuts, bevel cuts, التنميط, rabbeting, grooving, sanding and corner processing. Thanks to its robust design, low-wear technology and high level of availability, this double end tenoning machine machine is exactly the right choice for manufacturing doors, fronts and panels.

• User-friendly PLC control

• Width setting through touch-sensing screen for increased accuracy and convenience

• Moulding spindle is directly driven by a high-frequency motor, providing 7,500 rpm spindle speed

• Link chains are driven by a frequency-inverted motor, ensuring synchronized feed at both sides

• 6 و 8 مغزل (optional)

Double end tenoner provides the best way to productivity and versatility

• The double end tenoner is designed and engineered for high quality wooden furniture with profitable production.

• They are ideal for producing solid wood and panel furniture and wooden doors.

• The series of double end tenoner provides various functions, such as double end sizing, profile moulding. It’s a highly automated machine that creates the efficiency you’ve come to expect.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

أدوات القطع

لا تحتوي معظم آلات النجارة الخشبية على أدوات القطع عند التصدير, لأن مصانع النجارة المختلفة تحتاج إلى نوع مختلف من القواطع. لتحسين خدمتنا, يمكننا مساعدتك في شراء أدوات القطع.

محرك مخصص

في جدول المعلمات الفنية لدينا 4 سوي على الوجهين متلهف, يمكنك رؤية التكوين القياسي لدينا. إذا كنت بحاجة, يمكننا ترقية طاقة المحرك لك.

نظام الناقل

من أجل توفير تكلفة العمالة وتحسين الإنتاجية لك, يمكننا الجمع 4 تم تجهيز مستوي لكم مع نظام التغذية والتغذية الخارجية.

حديد الزهر بالكامل

قطعة واحدة ثقيلة جدًا, يتم معالجة إطار آلة الحديد الزهر بالحرارة خصيصًا لتحقيق أقصى قدر من الثبات والصلابة من خلال التكوين القياسي.

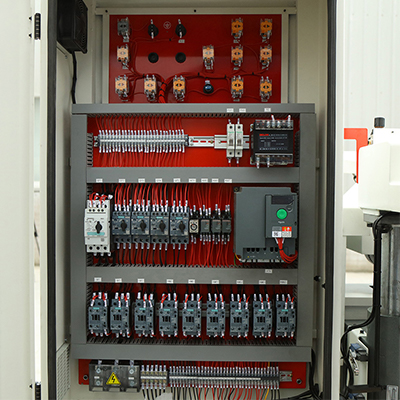

سيمنز الكهربائية

تضمن المنتجات والأجهزة الكهربائية Siemens وSchneider أن الآلة بأكملها تعمل بشكل جيد مع أداء مستقر

GUIDE RAIL

Feeding guide rail is cast with sectional combination structure. 1300mm long feeding area has a feature of easy assembling, stable precision, especially suitable for large size work piece.

SYNCHRONOUS MOVEMENT

Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

SCORING + HOGGER UNIT

Up pressing mechanism is configured with NC electric lift, ensuring the stable pressing and more convenient and quick operating.

ADVANCED PLC CONTROL

The operating system is equipped with an imported computer touch screen and PLC for joint control, وهو بديهي ومريح للعمل, which can effectively reduce adjustment time and improve production efficiency.