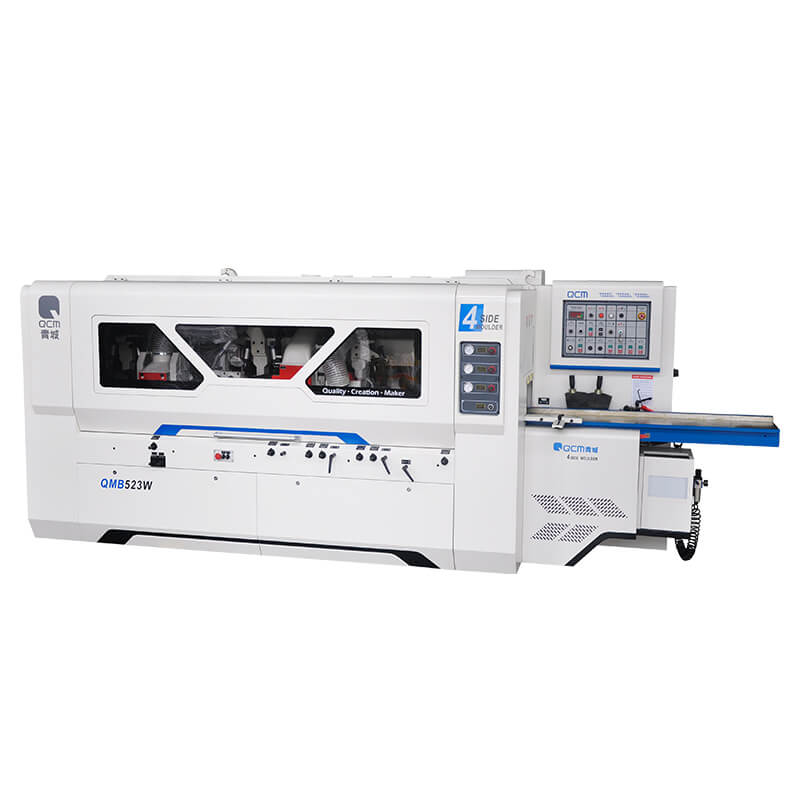

Nama Produk: Empat sisi planer kayu qmb723gh

Lebar kerja: 20-230mm

Ketebalan kerja: 10-160mm

Spindle: 7

Kecepatan makan: 6-60m/my

Aplikasi: 4 Moulder Perencana Samping, pemotongan berat untuk balok kayu besar, rumah kayu, Sawmill Woodworking, Pabrik furnitur dll.

50+ pengalaman tahun

3 garansi tahun

Dukungan teknis 7*12h

standar dan bersatu

| Spesifikasi | QMB623GH | QMB723GH | QMB823GH | |

|---|---|---|---|---|

| Lebar kerja | mm | 20-230 | 20-230 | 20-230 |

| Ketebalan kerja | mm | 10-160 | 10-160 | 10-160 |

| Min. panjang kerja(intermiten/kontinu) | mm | 720/280 | 720/380 | 720/280 |

| Adalah. spindle | mm | Φ50 | Φ50 | Φ50 |

| Adalah. roller makan | mm | Φ140 | Φ140 | Φ140 |

| Kecepatan makan | m/my | 10-60 | 6-60 | 10-60 |

| Kecepatan rotasi spindel | r/mnt | 7000 | 7000 | 7000 |

| Kekuatan total | KW/HP | 68.37/91 | 106.22/141 | 91.09/123.5 |

| Suction Hood Dia. | mm | 6*Φ180 | 7*Φ180 | 8*Φ180 |

| Dimensi keseluruhan | mm | 5660*2100*1900 | 5660*2100*1900 | 6580*2080*1960 |

| Berat | kg | 8300 | 8800 | 10800 |

Solusi profesional: Produksi dan pemrosesan massal efisiensi tinggi di pabrik papan sambungan jari besar dan pabrik strip kayu

Tubuh mesin terbuat dari coran berkualitas tinggi, diproses dengan pemesinan presisi, dengan kinerja yang stabil dan kekakuan yang baik.

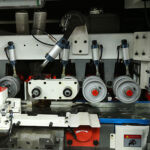

Diameter spindel φ50mm, setelah perakitan presisi, pengobatan keseimbangan dinamis, berjalan lancar, kekakuan yang baik, Presisi yang baik.

Meja kerja yang dapat dipindahkan dilengkapi dengan 2 set rol drive mengambang pneumatik, yang membuat makanan stabil dan kuat.

Level atas belakang, Pemotong bawah kedua dan ketiga dilengkapi dengan gabungan lurus otomatis (mekanisme penajaman ) Untuk mencapai penajaman blade otomatis untuk memenuhi kebutuhan pemrosesan pemberian makan berkecepatan tinggi.

Semua pemotong horizontal dilengkapi dengan struktur dukungan eksternal hidrolik, Menggunakan pistol oli bertekanan tinggi untuk memberikan tekanan pada dukungan eksternal untuk memastikan kinerja pemotongan kecepatan tinggi.

Rol tekanan samping spindel vertikal kiri, Struktur pemutus chip dan pelat tekanan depan pisau atas semuanya dilengkapi dengan tekanan silinder untuk memastikan pemberian makan material yang halus.

Pemotong atas depan dan belakang mengadopsi pengangkatan sinkron listrik, juga bisa disempurnakan secara manual, Operasi yang nyaman dan cepat.

Peralatan Listrik Mengadopsi Merek Siemens, Antarmuka HMI Human-Machine, Operasi yang nyaman dan cepat.

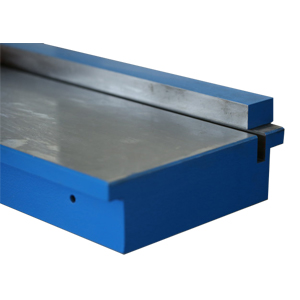

Meja In-Feeding

Tabel kami yang masuk 4 Moulder planer samping dapat diperpanjang, Panjang khusus sesuai dengan kebutuhan Anda.

Daya motor

Di tabel parameter teknis kami 4 Planer sisi Moulder, Anda dapat melihat konfigurasi standar kami. Jika Anda membutuhkan, Kami dapat meningkatkan daya motor untuk Anda.

di dalam & keluar memberi makan

Untuk menghemat biaya tenaga kerja dan meningkatkan produktivitas untuk Anda, kita bisa menggabungkan 4 Planer sisi untuk Anda dengan sistem in-feeding dan out-feeding.

Alat pemotong

Sebagian besar mesin kayu kami tidak memiliki alat pemotongan saat ekspor, Karena pabrik kayu yang berbeda membutuhkan jenis pemotong yang berbeda. Untuk meningkatkan layanan kami, Kami dapat membantu Anda membeli alat pemotong.

bodi mesin casting

Empat sisi perencana kayu memiliki bodi mesin besi casting satu potong ekstra berat. Ini khusus dirawat panas untuk stabilitas dan kekakuan maksimum dengan konfigurasi standar.

SIEMENS LISTRIK

Kita 4 Perencana sisi Moulders menggunakan produk dan peralatan listrik Siemens dan Schneider memastikan seluruh mesin berjalan dengan baik dengan kinerja yang sesuai

Silinder Airtac

Tekanan pneumatik dari rol feed dapat dengan mudah disusun untuk memberikan efek makan yang luar biasa bagi kami 4 planer sisi.

Kandang keselamatan

Sound baja pengukur berat penuh sound safety safety safety berfungsi sebagai penjaga chip dan membantu 4 Planer sisi Moulder untuk mengurangi kebisingan dan memiliki pencahayaan bebas strobo.

presisi tinggi

Semua spindel adalah presisi yang dibangun dan secara khusus dipanaskan untuk disediakan 4 Planer sisi moulder stabilitas pemotongan maksimum dan akurasi permanen.

Gearbox tugas berat

Rol feed dari planer moulder digerakkan melalui kombinasi poros universal dan gearbox ekstra berat, Pastikan tidak ada kehilangan transmisi daya. Efek pemberian makan yang lancar terjamin.

Pemberian makan yang luar biasa

Kita 4 Planer sisi Moulder memiliki lebih banyak rol bertenaga atas dan bawah daripada kebanyakan moulder empat sisi pesaing. Dan ini adalah alasan penting untuk kinerja pemberian makan yang luar biasa.

didengar-chromed

Seluruh tabel in-feed besi cor dipanaskan dirawat untuk stabilitas maksimal. Tabel in-feed & Penyesuaian pagar 4 Moulder sisi dengan cepat dicapai dengan cara pengungkit cepat.