50+ pengalaman tahun

3 garansi tahun

Dukungan teknis 7*12h

standar dan bersatu

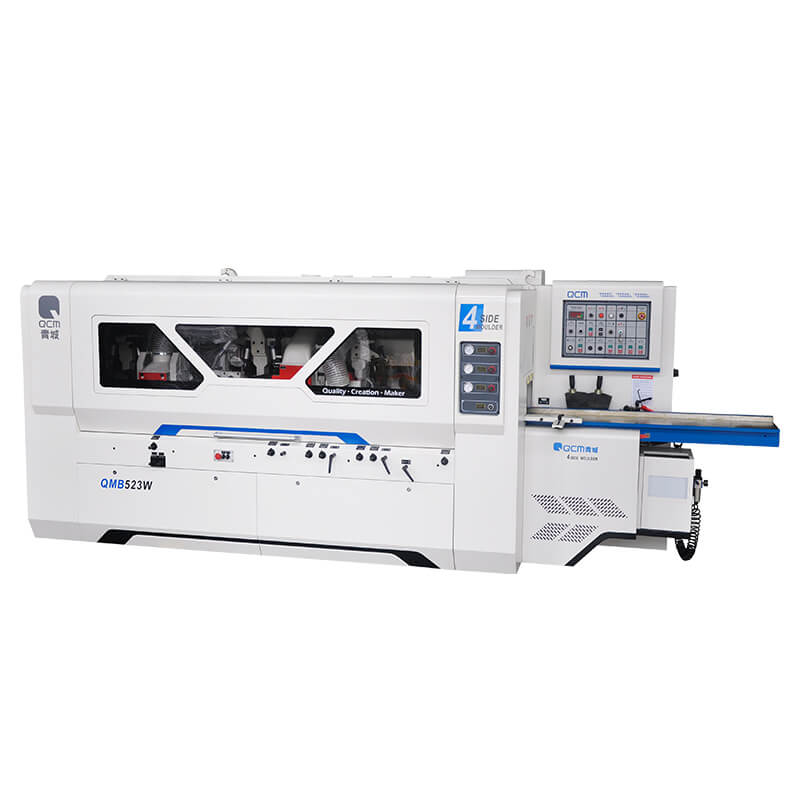

| Spesifikasi | QMB623A/AK | QMB523A | |

|---|---|---|---|

| Lebar kerja | mm | 20-230 | 20-230 |

| Ketebalan kerja | mm | 8-160 | 8-160 |

| Min. panjang kerja(intermiten/kontinu) | mm | 840/280 | 840/280 |

| Adalah. spindle | mm | Φ40 | Φ40 |

| Kecepatan makan | m/my | 6-36 | 6-36 |

| Kecepatan rotasi spindel | r/mnt | 6800 | 6800 |

| Kekuatan total | KW/HP | 47.25/63 | 38.25/51 |

| Suction Hood Dia. | mm | 6*Φ150 | 5*Φ150 |

| Dimensi keseluruhan | mm | 4960*1900*1700 | 4280*1900*1700 |

| Berat | kg | 5600 | 4600 |

QMB623A-K 4 side moulder has computer touch screen with memory system; while QMB523A and QMB623A does not have touch screen and no memory system, which can store 60 groups data.

QMB623A-K four side moulder has upper cutter lifting motor, and radial adjustment of the vertical spindle; while QMB623A need manual adjustment.

Professional solutions wood profile, four-side moulding of wooden house timber, Lantai kayu, wood line or solid wood furniture, and four-sided planing.

mouldings, fiberboard, wooden boards,

We are the only four side moulder manufacturer who has the casting workshop. Our woodworking machinery adopts integrated casting body. So our four side moulder planer have good performance, high precision and good stability, kekakuan yang baik.

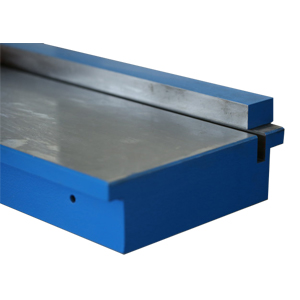

customized table

The in-feeding table of our four side moulder can be lengthened, Panjang khusus sesuai dengan kebutuhan Anda.

motor khusus

Di tabel parameter teknis kami 4 planer sisi, Anda dapat melihat konfigurasi standar kami. Jika Anda membutuhkan, Kami dapat meningkatkan daya motor untuk Anda.

Sistem Konveyor

Untuk menghemat biaya tenaga kerja dan meningkatkan produktivitas untuk Anda, we can combine four side moulder for you with in-feeding and out-feeding system.

Alat pemotong

Sebagian besar mesin kayu kami tidak memiliki alat pemotongan saat ekspor, Karena pabrik kayu yang berbeda membutuhkan jenis pemotong yang berbeda. Untuk meningkatkan layanan kami, Kami dapat membantu Anda membeli alat pemotong.

bodi mesin casting

planer moulder has extra heavy one-piece casting iron machine body. It’s specially heat treated for maximum stability and rigidity by standard configuration.

SIEMENS LISTRIK

Our planer moulder use Siemens and Schneider electrical products and appliances insure the whole machine run well with a suitable performance

Silinder Airtac

Pneumatic pressure of the feed rollers can be easily setted to provide an outstanding feeding effect for our planer moulder.

Kandang keselamatan

The full heavy gauge steel sound insulated safety enclosure serves as a chip guard and helps moulder planer to reduce noise and has strobe free lighting.

presisi tinggi

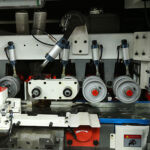

All spindles are precision constructed and specially heat treated to provide planer moulder maximum cutting stability and permanent accuracy.

Gearbox tugas berat

The feed rollers of four side moulder are driven through a combination of extra heavy universal shafts and gearbox, Pastikan tidak ada kehilangan transmisi daya. Efek pemberian makan yang lancar terjamin.

Pemberian makan yang luar biasa

Kita 4 side moulder has more top and bottom powered rollers than most competitor’s four side moulder. Dan ini adalah alasan penting untuk kinerja pemberian makan yang luar biasa.

didengar-chromed

Seluruh tabel in-feed besi cor dipanaskan dirawat untuk stabilitas maksimal. Tabel in-feed & fence adjustment of four sided moulder is quickly accomplished by means of a quick-setting levers.