50+ pengalaman tahun

3 garansi tahun

Dukungan teknis 7*12h

standar dan bersatu

| Spesifikasi | MXK3155A | |

|---|---|---|

| Lebar kerja | mm | 500 |

| Ketebalan kerja | mm | 12-25 |

| Kecepatan spindel | r/mnt | 18000 |

| Kekuatan total | KW/HP | 3/4 |

| Power of spindle motor | KW/HP | 1.1/1.5 |

| X-axis motor | KW/HP | 0.75/1 |

| Y-axis motor | KW/HP | 0.75/1 |

| Cutting period | s | 3-30 |

| Dimensi keseluruhan | mm | 1700*750*1250 |

| Berat | kg | 600 |

1. The X and Y axes adopt imported linear guides and ball screw drive structure, with flexible movement, kinerja yang stabil dan presisi yang baik.

2. The X and Y axes adopt Delta’s high-efficiency full-servo drive system. It runs smoothly and has stable performance.

3. Adopt the international brand Delta motion controller and touch screen control to realize the man-machine interface, the operation is simple and easy to learn, and no special training is required. The parameters can be easily input and modified through the touch screen, and the tool wear can be compensated. The operation is simple, convenient and fast.

4. Each group of the pressing system is equipped with 4 pressing cylinders to ensure stable pressing and good processing quality.

5. Additional functions: Change the tool to reset the program, and can perform tenon processing of different shapes such as round tenon, waist tenon and square tenon.

This CNC dovetail tenoning machine is mainly to meet the needs of processing dovetail tenons in the solid wood furniture manufacturing industry. The maximum processing width is 500mm, and the maximum processing thickness is 25mm. It has the advantages of stable performance, high processing efficiency and high cost performance. It can process not only various dovetail tenons, but also various shapes of tenons. It is mainly used in the furniture manufacturing industry to process the drawer coaming dovetail tenon at one time. It is an ideal equipment for efficient processing in solid wood furniture manufacturing industry.

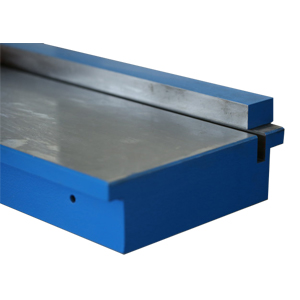

customized table

Tabel kami yang masuk 4 Moulder planer samping dapat diperpanjang, Panjang khusus sesuai dengan kebutuhan Anda.

motor khusus

Di tabel parameter teknis kami 4 Planer sisi Moulder, Anda dapat melihat konfigurasi standar kami. Jika Anda membutuhkan, Kami dapat meningkatkan daya motor untuk Anda.

Sistem Konveyor

Untuk menghemat biaya tenaga kerja dan meningkatkan produktivitas untuk Anda, kita bisa menggabungkan 4 Planer sisi untuk Anda dengan sistem in-feeding dan out-feeding.

Alat pemotong

Sebagian besar mesin kayu kami tidak memiliki alat pemotongan saat ekspor, Karena pabrik kayu yang berbeda membutuhkan jenis pemotong yang berbeda. Untuk meningkatkan layanan kami, Kami dapat membantu Anda membeli alat pemotong.

AUTOMATIC LUBRICATORE

Pelumas otomatis memberikan minyak pelumasan yang sering ke rantai ulat ulat.

GOOD DRIVE STRUCTURE

X, Y axis adopts imported linear guide rail and ball screw drive structure, which has flexible movement, stable performance and good accuracy.

HIGH EFFICIENCY DRIVE SYSTEM

The X, Y axis adopts Delta’s high-efficiency full servo drive system. It runs smoothly and has stable performance.

SIMPLE OPERATION

Adopt international brand Delta motion controller and touch screen control, the operation is simple and easy to learn. And tool wear can be compensated. The operation is simple, convenient and fast.

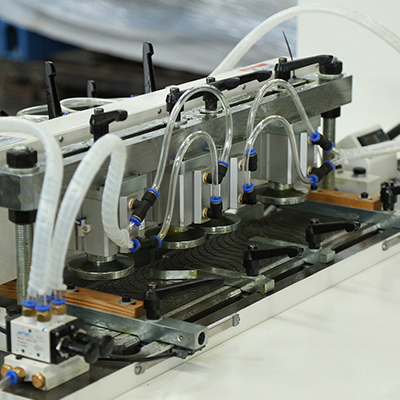

PRESSING SYSTEM

Each group of pressing system is equipped with 4 pressing cylinders to ensure stable pressing and good processing quality.