50+ pengalaman tahun

3 garansi tahun

Dukungan teknis 7*12h

standar dan bersatu

| Spesifikasi | QMX8025M | QMX6025M | QMX3826D*8 | QMX3820D | |

|---|---|---|---|---|---|

| Lebar kerja | mm | 300-2500 | 300-2500 | 300-2600 | 300-2000 |

| Ketebalan kerja | mm | 10-120 | 10-120 | 10-70 | 10-70 |

| Jarak blok makan | mm | 500 | 500 | 240 | 240 |

| Kecepatan makan | m/my | 6-36 | 6-36 | 5-20 | 5-20 |

| Melihat kecepatan poros | r/mnt | 3000 | 3000 | 3000 | 3000 |

| Kecepatan sumbu penggilingan | r/mnt | 7500 | 7500 | 7000 | 7000 |

| Kecepatan spindel gulung gesper | r/mnt | / | / | 8000 | / |

| Total daya motor | KW/HP | 47/64 | 41/56 | 26.06/35 | 20.95/28 |

| Diameter port vakum | mm | 8*Φ120 | 6*Φ120 | 8*Φ100 | 6*Φ100 |

| Dimensi mesin | mm | 4880*4650*1900 | 4880*4130*1890 | 4700*3350*1600 | 4100*2500*1460 |

| Berat | kg | 6500 | 6000 | 4300 | 3250 |

1. The machine body and its bed are integrally cast with high-quality castings, which are specially processed and precisely processed by the five-sided gantry machining center, dengan kinerja yang stabil, good rigidity and high precision. .

2. The main shaft adopts special materials, after special treatment, precision processing and assembly, the speed of the milling cutter is 7000r/min and the speed of the buckle shaft is 8000r/min, which has the advantages of stable operation and good processing quality.

3. The feeding adopts high-precision synchronous track connection and round bar guide rail guide structure to ensure stable operation, accurate positioning and good processing quality.

4. The fixed width system adopts imported linear guide rail and ball screw drive, and is equipped with a fixed protective cover to overcome the previous phenomenon of wood chip dust blocking the guide rail and ensure the precise width of the fixed width system.

5. The workbench panel is made of special wear-resistant synthetic material, which runs smoothly, has good processing quality and greatly improves wear resistance.

6. The selected feeding system is equipped with a hard-tooth surface reducer and an imported frequency converter to realize variable-frequency feeding. The feeding speed can reach 5-20m/min. The operation is convenient and fast, and it is suitable for processing various materials.

7. The material pressing beam adopts double-column material pressing structure and electric lifting structure to ensure stable material pressing, guarantee the quality of processed products, dan operasinya nyaman dan cepat.

Mainly used for milling and tenoning processing of solid wood flooring, engineered flooring, and laminate flooring double-end trimming machine. It is the ideal equipment for upgrading and upgrading of the majority of users in the floor processing industry.

Double end tenoner QMX3826D and QMX3820D are mainly designed and developed according to the needs of floor processing in the solid wood flooring and engineered wood floor processing industries. The front is up and down sawing, the middle milling shaft, and the back is double-end milling product with a universal milling shaft. The maximum processing width is 2600mm and the maximum processing thickness is 70mm, which can effectively meet the processing of snap tenons that cannot be completed by the six-axis floor double-end milling tenon.

Lebar pemrosesan yang disesuaikan

Lebar pemrosesan mesin tenun ganda dapat disesuaikan sesuai dengan kebutuhan Anda. 3000MM juga tersedia.

Alat pemotong

Sebagian besar mesin kayu kami tidak memiliki alat pemotongan saat ekspor, Karena pabrik kayu yang berbeda membutuhkan jenis pemotong yang berbeda. Untuk meningkatkan layanan kami, Kami dapat membantu Anda membeli alat pemotong.

motor khusus

Di tabel parameter teknis kami 4 Planer sisi Moulder, Anda dapat melihat konfigurasi standar kami. Jika Anda membutuhkan, Kami dapat meningkatkan daya motor untuk Anda.

Sistem Konveyor

Untuk menghemat biaya tenaga kerja dan meningkatkan produktivitas untuk Anda, kita bisa menggabungkan 4 Planer sisi untuk Anda dengan sistem in-feeding dan out-feeding.

Seluruh besi cor

One-piece ekstra berat, Bingkai mesin besi cor secara khusus dirawat untuk stabilitas dan kekakuan maksimum dengan konfigurasi standar.

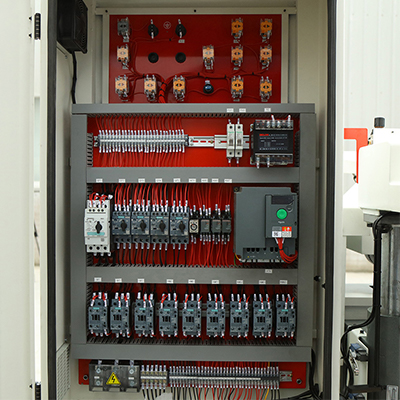

SIEMENS LISTRIK

Produk dan peralatan Siemens dan Schneider memastikan seluruh mesin berjalan dengan baik dengan kinerja yang stabil

Gerakan sinkron

Gerakan Lebar Kerja Worktable Menggunakan Panduan Linier Impor dan Struktur Pengaturan Lebar Otomatis CNC yang memiliki fitur penyesuaian yang mudah, Posisi yang tepat dan kemampuan keausan yang sangat baik.

Kontrol PLC tingkat lanjut

Sistem operasi dilengkapi dengan layar sentuh komputer yang diimpor dan PLC untuk kontrol bersama, yang intuitif dan nyaman untuk beroperasi, yang secara efektif dapat mengurangi waktu penyesuaian dan meningkatkan efisiensi produksi.