50+ pengalaman tahun

3 garansi tahun

Dukungan teknis 7*12h

standar dan bersatu

| Spesifikasi | SFR-R1300V | SFR-R700V | SFR-R1300D | |

|---|---|---|---|---|

| Lebar pemotongan pengamplasan | mm | 1300 | 700 | 1300 |

| Pengamplasan ketebalan pemotongan | mm | 3-100 | 3-160 | 3-160 |

| Panjang pemotongan pasir terpendek | mm | 300 | 300 | 330 |

| Kecepatan makan | m/my | 3-20 | 0-24 | 5-30 |

| The first sanding spindle dia. | mm | φ215 | φ215 | 300 |

| The seconde sanding spindle dia. | mm | φ215 | φ215 | 300 |

| Total daya motor | KW/HP | 29.17/39 | 21.47/29 | 38.67/52 |

| Ukuran pengamplasan sabuk | mm | 2100*1370 | 770*2100 | 1340*2200 |

| Vacuum port dia. | mm | 3*φ180/3*φ150 | 2*φ180/3*φ150 | 3*φ180/3*φ150 |

| Dimensi mesin | mm | 2120*2080*2300 | 2050*1510*2300 | 2520*2130*2350 |

| Berat mesin | kg | 3800 | 2950 | 4700 |

This product is mainly based on the needs of fine sanding in the furniture manufacturing industry. It is a floating primer sanding machine. The characteristics are that the worktable is fixed, the sand frame parts are adjusted by numerical control, and the speed of the sand belt is frequency-controlled. It has the advantages of high sand cutting precision and high efficiency. It is mainly used for primer grinding and pre-processing of materials (sanding before painting), and can also be used for assembly line production on NV and UV painting, which can greatly improve work efficiency.

1. A double-roller pressing structure is adopted between the two sand racks. The pressing rollers are equipped with 8 groups of pressing rollers, which have stable pressing, smooth feeding and good processing quality.

2. The rear and upper parts of each sanding part are equipped with electric swing air blowing and abrasive belt cleaning and dust removal devices, which can effectively remove dust on the surface of the abrasive belt, keep the abrasive belt clean, and prolong the service life of the abrasive belt.

3. The swing control of the sanding parts adopts the eccentric adjustment cylinder swing mechanism, and is equipped with imported photoelectric switches and travel switches for detection and control, which has the advantages of stable performance, fewer failures and good reliability.

4. The electrical components and frequency converters used in the product are of international brand Siemens, with stable performance and good reliability.

5. The beam support of the sand frame parts is made of high-quality castings. After special treatment and precision machining, its performance is stable, the deformation is small, and the precision is good.

6. The machine base and worktable are made of high-quality steel plates welded together. After special aging treatment and precision machining, they have stable performance and good precision.

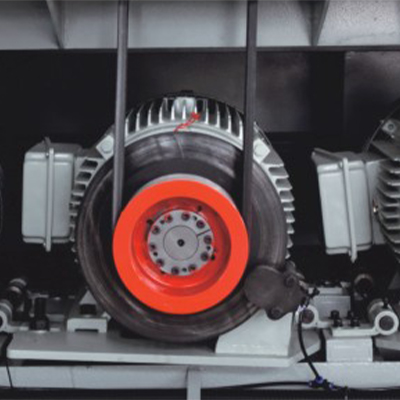

motor khusus

Di tabel parameter teknis kami mesin pengamplasan, Anda dapat melihat konfigurasi standar kami. Jika Anda membutuhkan, Kami dapat meningkatkan daya motor untuk Anda.

Sistem Konveyor

Untuk menghemat biaya tenaga kerja dan meningkatkan produktivitas untuk Anda, Kami dapat menggabungkan mesin pengamplasan untuk Anda dengan sistem in-feeding dan out-feeding otomatis.

di dalam motor setted

Motor untuk pengamplasan kasar, pengamplasan semi-halus, pengamplasan halus di dalam diatur , untuk membuat penampilan pembersihan.

Roller anti-reversal

Kelompok kedua roller pemalas adalah anti- roller pembalikan, untuk melindungi keamanan operator.

piring casting

Pelat pendukung terbuat dari casting berkualitas tinggi, Yang membuat mesin kami lebih stabil dan akurasi tinggi.

Rol tekanan ganda

Struktur rol tekanan ganda untuk memastikan pemberian makan yang lebih baik dan halus.

stabil dan tepat

Seri SPR-RP Dikonfigurasi dengan Modul Pemotong Perencana Spiral Presisi, dan di keyboard jenis penekan penekan penekanan. Itu dapat merencanakan dan mengampelas pada saat bersamaan, stabil dan tepat.

8 set rol makanan

Jenis SRR630S dilengkapi dengan 8 set rol makanan, 3 depan, 2 di tengah, 3 belakang. Jadi bisa berlaku untuk bahan lebih dari 230mm.