50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | SFR-R1300V | SFR-R700V | SFR-R1300D | |

|---|---|---|---|---|

| Anchura de corte de lijado | mm | 1300 | 700 | 1300 |

| Grosor de corte de lijado | mm | 3-100 | 3-160 | 3-160 |

| La longitud de corte de arena más corta | mm | 300 | 300 | 330 |

| Velocidad de alimentación | m/mi | 3-20 | 0-24 | 5-30 |

| The first sanding spindle dia. | mm | φ215 | φ215 | 300 |

| The seconde sanding spindle dia. | mm | φ215 | φ215 | 300 |

| Potencia total del motor | KW/HP | 29.17/39 | 21.47/29 | 38.67/52 |

| Tamaño del cinturón de lijado | mm | 2100*1370 | 770*2100 | 1340*2200 |

| Vacuum port dia. | mm | 3*φ180/3*φ150 | 2*φ180/3*φ150 | 3*φ180/3*φ150 |

| Dimensiones de la máquina | mm | 2120*2080*2300 | 2050*1510*2300 | 2520*2130*2350 |

| Peso de la máquina | kg | 3800 | 2950 | 4700 |

This product is mainly based on the needs of fine sanding in the furniture manufacturing industry. It is a floating primer sanding machine. The characteristics are that the worktable is fixed, the sand frame parts are adjusted by numerical control, and the speed of the sand belt is frequency-controlled. It has the advantages of high sand cutting precision and high efficiency. It is mainly used for primer grinding and pre-processing of materials (sanding before painting), and can also be used for assembly line production on NV and UV painting, which can greatly improve work efficiency.

1. A double-roller pressing structure is adopted between the two sand racks. The pressing rollers are equipped with 8 groups of pressing rollers, which have stable pressing, smooth feeding and good processing quality.

2. The rear and upper parts of each sanding part are equipped with electric swing air blowing and abrasive belt cleaning and dust removal devices, which can effectively remove dust on the surface of the abrasive belt, keep the abrasive belt clean, and prolong the service life of the abrasive belt.

3. The swing control of the sanding parts adopts the eccentric adjustment cylinder swing mechanism, and is equipped with imported photoelectric switches and travel switches for detection and control, which has the advantages of stable performance, fewer failures and good reliability.

4. The electrical components and frequency converters used in the product are of international brand Siemens, with stable performance and good reliability.

5. The beam support of the sand frame parts is made of high-quality castings. After special treatment and precision machining, its performance is stable, the deformation is small, and the precision is good.

6. The machine base and worktable are made of high-quality steel plates welded together. After special aging treatment and precision machining, they have stable performance and good precision.

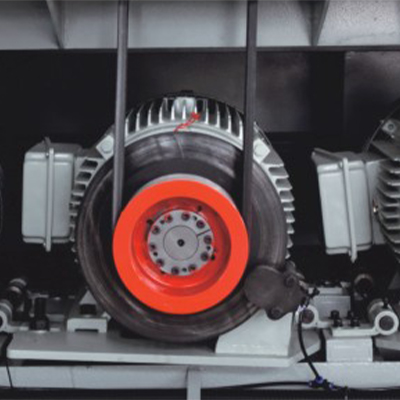

motor personalizado

En nuestra tabla de parámetros técnicos de la máquina de lijado, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

Sistema de transporte

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar máquinas de lijado para usted con un sistema automático de alimentación y alimentación de alimentación.

Dentro de motores establecidos

Motores para lijado grueso, lijado semi-fino, Las lijas finas están instaladas en el interior , Para hacer apariencia de limpieza.

rodillo anti-reverso

El segundo grupo de rolleros inactivos es anti- rodillo de inversión, para proteger la seguridad del operador.

placas de fundición

Las placas de soporte están hechas de casting de alta calidad., lo que hace que nuestra máquina sea más estable y de alta precisión.

Rodillo de doble presión

Estructura de rodillo de doble presión para garantizar una alimentación insignia y suave.

estable y precisamente

Serie SPR-RP configurada con módulo de cortador de cepillado de espiral de precisión, y en el tipo de teclado estructura de presión seccional. Puede planificar y lijarse al mismo tiempo, estable y precisamente.

8 Conjuntos de rodillos de alimentación

El tipo SRR630S está equipado con 8 Conjuntos de rodillos de alimentación, 3 frente, 2 en el medio, 3 trasero. Entonces puede aplicarse a Memails de más de 230 mm de longitud.