50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | SPR-RP1300 | SRRP1300C | SRP1300B | SRP630S | |

|---|---|---|---|---|---|

| Sanding cutting width | MM | 40-1300 | 40-1300 | 40-1300 | 40-630 |

| Sanding cutting thickness | MM | 3-120 | 3-120 | 3-160 | 3-180 |

| The shortest sand cutting length | MM | 520 | 500 | 620 | 230 |

| Planer shaft speed | m/s | 36 | / | / | / |

| Speed of the first group of sanding belt | m/s | 19 | 21 | 19 | 19 |

| Speed of the first group of sanding belt | m/s | 18.5 | 19 | 18 | 16 |

| Speed of the third group of sanding belt | m/s | / | 18.5 | / | / |

| Vitesse d'alimentation | m / mon | 6-30 | 6-30 | 6-30 | 6-30 |

| Sanding belt size | MM | 1330*2200 | 1330*2200 | 1330*2200 | 650*2100 |

| Puissance totale du moteur | KW / HP | 77.12/103 | 95.62/128 | 57.12/77 | 20.74/28 |

| Vacuum port of dia. | MM | 9*φ150 | 7*φ150 | 5*φ150 | 5*φ150 |

| Dimensions des machines | MM | 2850*2050*2200 | 2800*2040*2200 | 2260*2060*2230 | 2120*1270*2050 |

| Machine weight | kg | 5150 | 5050 | 3700 | 1900 |

This product is a three-frame wide-band sanding machine product developed according to the high-quality needs of users in the solid wood finger-joint panel industry and blockboard processing industry. The first sand frame is coarse sand, the second sand frame is semi-fine sand, and the third sand frame is finely polished. The maximum sanding width is 1300mm and the maximum sanding thickness is 120mm. Mainly used for fine sanding of large boards such as finger-jointed panels and blockboards.

1. The beam support of this machine tool adopts high-quality castings, which has good shock absorption, stable performance and good precision.

2. The worktable is welded with thick steel plate and large angle steel, and has been treated with special stress relief and precision machining. Its performance is stable and durable.

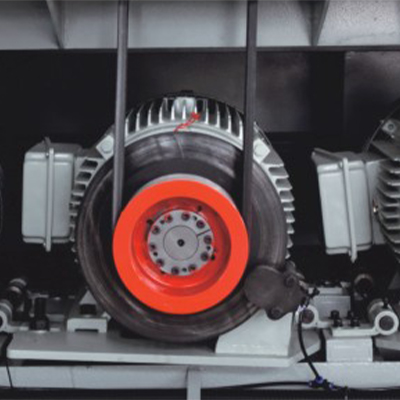

3. The three sets of motors of this machine tool, which are coarse sand, semi-fine sand and fine sand, all adopt built-in structure, which has the advantages of compact structure and beautiful appearance.

4. Equipped with 5 groups of idler pressure rollers, and the second group in front adopts the safety structure of anti-reverse rollers to prevent the sheet from rebounding and hurting people during the processing.

5. The feeding system is equipped with a combination of heavy-duty hard-tooth surface reducer and frequency converter.

6. Abnormal situation protection function: When the machine tool has abnormal conditions in normal use, such as: emergency stop, low air pressure, broken belt, running belt, etc., the worktable will automatically drop to prevent the abrasive belt from contacting the workpiece strongly and damaging the machine tool or abrasive belt.

7. The discharge side is equipped with a brush roller dust-removing brush mechanism to remove dust on the surface of the workpiece

Moteur personnalisé

In our technical parameter table of sanding machine, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

Système de convoyeur

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, we can combine sanding machines for you with automatic in-feeding and out-feeding system.

inside setted motors

Motors for coarse sanding, semi-fine sanding, fine sanding are inside setted , to make cleaning appearance.

anti-reversal roller

The second group of idler rollers is anti- reversal roller, to protect the safety of the operator.

casting plates

The support plates are made of high quality casting, which makes our machine more stable and high accuracy.

Double pressure roller

Double pressure roller structure to ensure seady and smooth feeding.

stablly and precisely

SPR-RP series configured with precision spiral planing cutter module, and in keyboard type sectional pressuring structure. It’s can plan and sanding at the same time, stablly and precisely.

8 sets feeding rollers

SRR630S type is equipped with 8 sets feeding rollers, 3 front, 2 in middle, 3 rear. So it can apply to materails over 230mm length.