Nom de produit: planing and sawing machine ML9620HM

Largeur de travail: 20-200MM

Épaisseur de travail: 10-200MM

Fuseau: 2 spindles for saw+ 4 spindles for moulder

Vitesse d'alimentation:5-25m / mon

Function: the combination woodworking machine for multi-blade rip saw and 4 side planer moulder machine

50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | ML9620HM | ML9620M | ML9620SMF | ML9616SM | |

|---|---|---|---|---|---|

| Largeur de travail | MM | 20-200 | 20-200 | 20-200 | 35-160 |

| Épaisseur de travail | MM | 10-200 | 10-125 | 10-120 | 15-120 |

| Min. durée de travail | MM | 550/480 | 650/480 | 650/480 | 650/480 |

| Saw spindle Dia. | MM | Φ50 | φ40 | Φ50 | Φ50 |

| Saw spindle speed | r / min | 4500 | 4500 | 4000 | 4000 |

| Planer spindle dia. | MM | φ40 | φ40 | φ40 | φ40 |

| Planer spindle speed | r / min | 6800 | 6800 | 6800 | 6800/8000 |

| Vitesse d'alimentation | m / mon | 5-25 | 5-25 | 6-30 | 6-30 |

| Puissance totale | KW / HP | 94.5/126 | 82.25/110 | 72.75/97 | 58.25/80 |

| Diamètre de la hottes. | MM | 3*φ150+4*φ120 | 3*φ150+4*φ120 | 6*φ150 | 2*φ150+4*φ120 |

| Overall dimension | MM | 4580*1800*1750 | 4530*1680*1630 | 4420*1790*1750 | 4170*1530*1720 |

| Poids | kg | 4600 | 4300 | 4850 | 3750 |

1. The saw blade can be installed directly on the saw shaft. The saw blade adopts a small diameter and a thin saw path to save material.

2. The left and right vertical shafts are heightened, and the maximum processing height is 200mm to meet the processing of wooden beams and wooden houses.

3. Electric lifting structure, easy to operate.

4. Increase the power of the motor to meet the processing requirements of large square material planing and multi-blade sawing.

5. The pressure plate in front of the upper knife adopts a cylinder pressing material structure to improve the smoothness of feeding.

6. Equipped with automatic air jet, water jet or oil jet device as standard to dissipate heat and cool the saw blade, improve the service life of the saw blade and the quality of the processed parts.

Professional solution for large-scale square material process in the anti-corrosion wood processing industry and the wood beam and wooden house processing industry. This planing and sawing machine combinds four-sided moulder and up-down saw.It’s firstly plan four sides of large square materials, and then sawing up and down into pieces.It has high production efficiency and saves materials.Equipped with automatic air jet, water jet or oil jet device as standard to cool the saw blade, improve the service life of the saw blade and the quality of the processed parts.

customized trimming cutter

Le tableau de travail de notre 4 Le moulin à planeur latéral peut être allongé, longueur personnalisée en fonction de vos exigences.

Outils de coupe

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

saw blade

Afin d'économiser le coût de la main-d'œuvre et d'améliorer la productivité pour vous, Nous pouvons combiner 4 Planeur à côte avec un système de travail et de hors-d'alimentation.

FONTE ENTIÈRE

Une pièce extra lourde, Le cadre de la machine en fonte est spécialement traité thermiquement pour une stabilité et une rigidité maximales grâce à la configuration standard.

ANTI-REBOUND SAFETY DEVICE

The anti-rebound safety device located on the infeed ensures operational safety.

Wear resistance guide track

The casting guide track and chain plate are made of special materials, specially processed and precisely processed, with high surface hardness, high precision and good wear resistance

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

Dust Removal Brush

The dust removal brush made of special materials is matched with a quantitative oil injection device to clean and lubricate the chain plates in real time

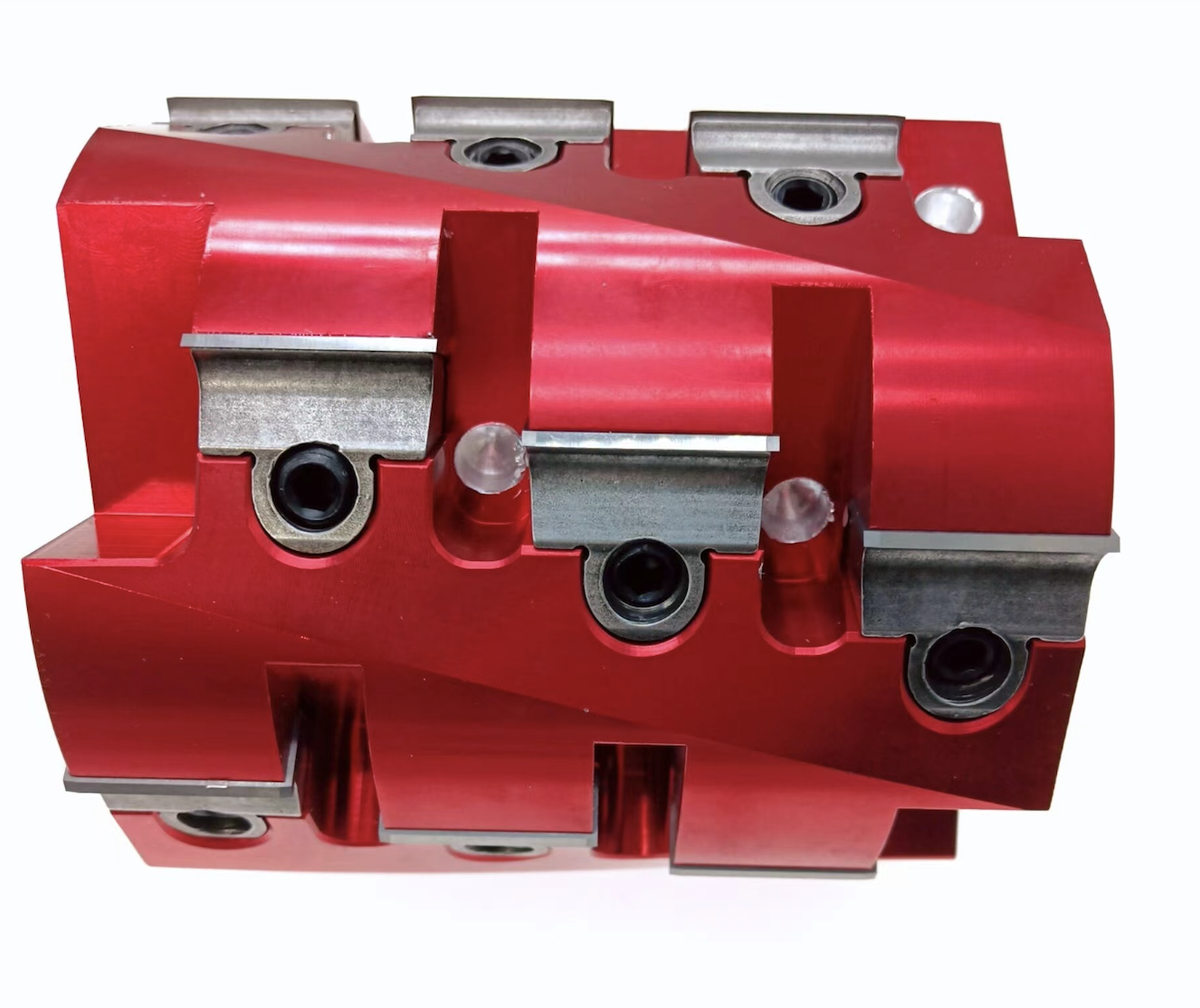

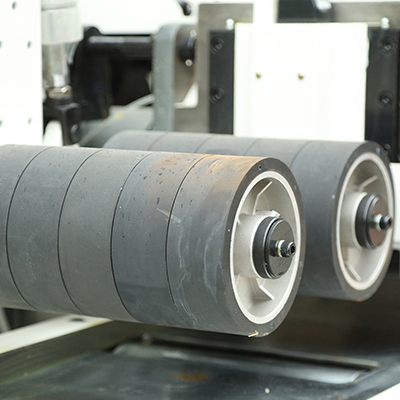

HIGH PRECISION SPINDLE

All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy.

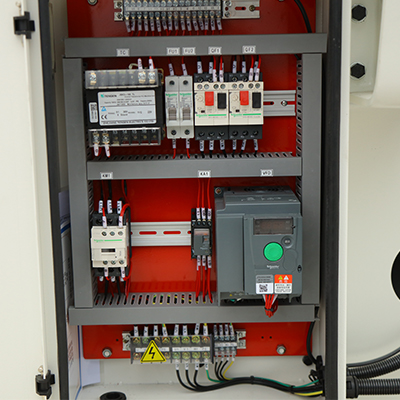

PROFESSIONAL ELECTRICAL APPLIANCES

Les produits et appareils électriques Siemens et Schneider garantissent le bon fonctionnement de l'ensemble de la machine avec des performances stables

CAST IRON CHROMED FEED TABLE

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.