50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | ML9620HM | ML9620M | ML9620SMF | ML9616SM | |

|---|---|---|---|---|---|

| Ancho de trabajo | mm | 20-200 | 20-200 | 20-200 | 35-160 |

| Espesor de trabajo | mm | 10-200 | 10-125 | 10-120 | 15-120 |

| Mínimo. longitud de trabajo | mm | 550/480 | 650/480 | 650/480 | 650/480 |

| Saw spindle Dia. | mm | Φ50 | Φ40 | Φ50 | Φ50 |

| Saw Spindle Speed | r/min | 4500 | 4500 | 4000 | 4000 |

| Planer spindle dia. | mm | Φ40 | Φ40 | Φ40 | Φ40 |

| Planer spindle speed | r/min | 6800 | 6800 | 6800 | 6800/8000 |

| Velocidad de alimentación | m/mi | 5-25 | 5-25 | 6-30 | 6-30 |

| Potencia total | KW/HP | 94.5/126 | 82.25/110 | 72.75/97 | 58.25/80 |

| Dié de campana de succión. | mm | 3*φ150+4*φ120 | 3*φ150+4*φ120 | 6*Φ150 | 2*φ150+4*φ120 |

| Overall dimension | mm | 4580*1800*1750 | 4530*1680*1630 | 4420*1790*1750 | 4170*1530*1720 |

| Peso | kg | 4600 | 4300 | 4850 | 3750 |

The planing and sawing machine combines four-sided planer and left/right vertical shafts multi-blade saw, can plan and saw at one time.

It is also possible to perform four-sided planing and forming processing on the slicing saw without the left and right vertical axes.

It has the advantage of reducing labor, improving production efficiency, saving materials in processing, and using one machine for multiple purposes.

The discharge side is equipped with four sets of vertical active feeding rollers at the front and rear. Ensure the smoothness of multi-blade sawing and feeding, overcome the phenomenon of blackening of the processed board surface, and the quality of the processed surface is good.

Professional solution for the solid wood processing industry for sauna panels, wall panels, floor panels and bedding panels.It is a planing saw machine that combines a four-sided planer with a left and right vertical axis multi-blade saw.It can simultaneously carry out the four-sided moulding and planing of the square material and the left and right vertical axis slice sawing and slicing operations.Ventajas: high production efficiency, material saving in processing and good quality of processed flakes.

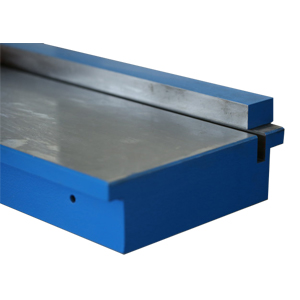

mesa personalizada

La mesa de alimentación de nuestro 4 Player de cepillador lateral se puede alargar, Longitud personalizada de acuerdo con sus requisitos.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

Sistema de transporte

Para ahorrar el costo laboral y mejorar la productividad para usted, Podemos combinar 4 Suministro para usted con un sistema de alimentación y alimentación.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

Hierro fundido entero

Extra pesada de una pieza, El marco de la máquina de hierro fundido es especialmente tratado térmicamente para obtener la máxima estabilidad y rigidez por configuración estándar.

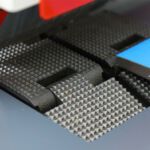

Dispositivo de seguridad antirorbista

El dispositivo de seguridad antigüense ubicado en la información garantiza la seguridad operativa..

Pista de guía de resistencia al desgaste

La pista de la guía de fundición y la placa de cadena están hechas de materiales especiales., especialmente procesado y procesado con precisión, con alta dureza superficial, Alta precisión y buena resistencia al desgaste

Lubricador automático

El lubricador automático ofrece aceite de lubricación frecuente a la cadena de oruga.

Cepillo de eliminación de polvo

El cepillo de extracción de polvo hecho de materiales especiales se combina con un dispositivo de inyección de aceite cuantitativo para limpiar y lubricar las placas de cadena en tiempo real

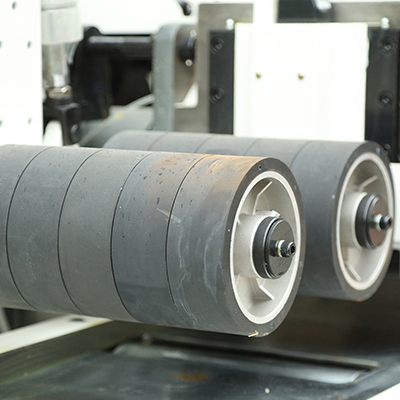

Eje de alta precisión

Todos los husillos son de precisión construidos y están especialmente tratados térmicamente para proporcionar la máxima estabilidad de corte y precisión permanente.

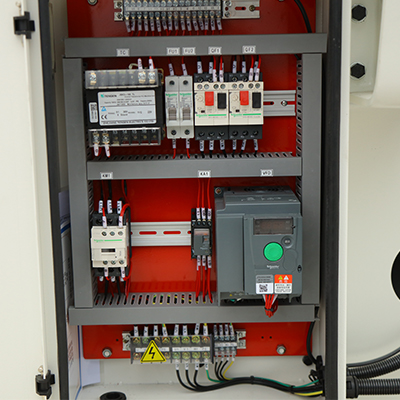

Electrodomésticos profesionales

Los productos y electrodomésticos de Siemens y Schneider aseguran que toda la máquina funcione bien con un rendimiento estable

Mesa de alimentación cromada de hierro fundido

Toda la mesa de alimentación cromada de hierro fundido es la normalización tratada térmicamente para la máxima estabilidad. Mesa de coeficiente & El ajuste de la valla se realiza rápidamente mediante una palancas rápidas.