50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMJ145H | QMJ143S | QMJ143E | MJ1440E | |

|---|---|---|---|---|---|

| Máximo. ancho de trabajo | mm | 500 | 300 | 300 | 300 |

| Espesor de trabajo | mm | 10-170 | 10-85 | 10-120 | 10-115 |

| Mínimo. longitud de trabajo | mm | 740 | 530/200 | 600/300 | 450 |

| Saw Spindle Dia. | mm | Φ60 | Φ55 | Φ55 | Φ50 |

| Reducción de la manga del manguito. | mm | Φ80 | Φ70 | Φ70 | Φ70 |

| Saw Spindle Speed | r/min | 2600 | 4000 | 4000 | 4500 |

| Velocidad de alimentación | m/mi | 3-24 | 4-30 | 4-30 | 6-24 |

| Potencia total | KW/HP | 81.25/109 | 32.57/43.5 | 39.57/52.7 | 33.32/45 |

| Dié de campana de succión. | mm | 2*Φ150 | 2*Φ150 | 2*Φ150 | 2*Φ150 |

| Dimensiones generales | mm | 4850*2020*1880 | 1930*1580*1560 | 2200*1500*1580 | 2300*1190*1480 |

| Peso | kg | 4250 | 2250 | 2300 | 1900 |

1. El cuerpo y el banco de trabajo de la máquina de sierra de sierra de múltiples luces están hechas de piezas fundidas de alta calidad, que son especialmente fundidos y maquinados con precisión, con rendimiento estable y buena precisión.

2. La cadena transportadora y el riel guía demáquina de sierra de rasguño de múltiples lucesestán hechos de materiales especiales resistentes al desgaste, que están especialmente procesados y mecanizados con precisión, con larga vida útil;

3. El dispositivo triple anti-rebote superior e inferior está equipado para garantizar una operación segura y confiable;

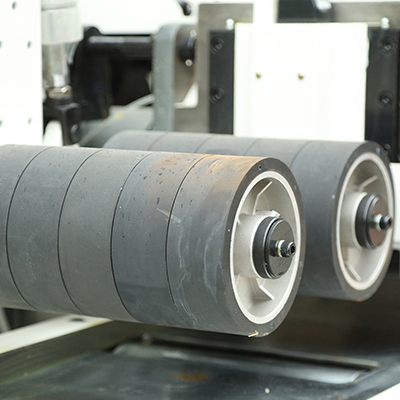

4. El huso demáquina de sierra de rasguño de múltiples lucesestá hecho de material especial, procesamiento de precisión, Tratamiento de equilibrio dinámico, y ensamblaje de precisión, operación estable y alta precisión;

5. Equipado con bomba de inyección automática de aceite automática de microcomputador importada con cronometrado, punto fijo y lubricación cuantitativa, con protección contra el cierre de escasez de aceite para garantizar el uso normal y la vida útil de la máquina;

6. Caja de desaceleración de transmisión de par gran importada, alimentación fuerte y poderosa;

7.Configurado con protección lateral y dispositivo de falla de energía para proteger completamente la seguridad humana y de la máquina;

8. Todos los componentes eléctricos y las piezas de transmisión son de buenas marcas y componentes, rendimiento estable;

9. La alimentación adopta la conversión de frecuencia para ajustar la velocidad, adaptarse a una variedad de materiales y grosor de los requisitos de procesamiento de madera.

Solución profesional: Haga un corte de rasgadura de múltiples luces para madera gruesa de menos de 120 mm. Cuerpo de máquina de fundición pesada y estable, y equipado con guía V avanzada y placas de cadena, y el eje de sierra tiene suficiente resistencia y rigidez para hacer un corte de múltiples salas. Perfecto para lápiz, y pequeños productos de madera similares.

Tenemos diferentes tipos de máquina Rip Saw Multi-Blade, como qmj143e, QMJ145H, QMJ143S, QMJ1440E.

Ambos husillos de huso o dos husos (máquina de sierra de rasguño arriba y abajo) están disponibles, con ancho de trabajo de 200-500 mm.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

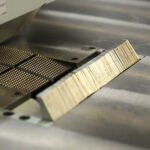

Cuchilla de sierra

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

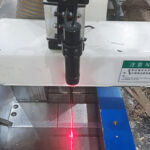

Guía láser

Para sierra de rasgón recta y sierra de rasgón de hoja única, Los clientes agregarán guía láser para un mejor corte, El corte será más preciso. La línea recta será más recta.

Hierro fundido entero

Extra pesada de una pieza, El marco de la máquina de hierro fundido es especialmente tratado térmicamente para obtener la máxima estabilidad y rigidez por configuración estándar.

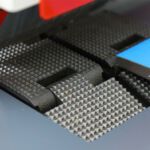

Dispositivo de seguridad antirorbista

El dispositivo de seguridad antigüense ubicado en la información garantiza la seguridad operativa..

Pista de guía de resistencia al desgaste

La pista de la guía de fundición y la placa de cadena están hechas de materiales especiales., especialmente procesado y procesado con precisión, con alta dureza superficial, Alta precisión y buena resistencia al desgaste

Lubricador automático

El lubricador automático ofrece aceite de lubricación frecuente a la cadena de oruga.

Cepillo de eliminación de polvo

El cepillo de extracción de polvo hecho de materiales especiales se combina con un dispositivo de inyección de aceite cuantitativo para limpiar y lubricar las placas de cadena en tiempo real

Eje de alta precisión

Todos los husillos son de precisión construidos y están especialmente tratados térmicamente para proporcionar la máxima estabilidad de corte y precisión permanente.

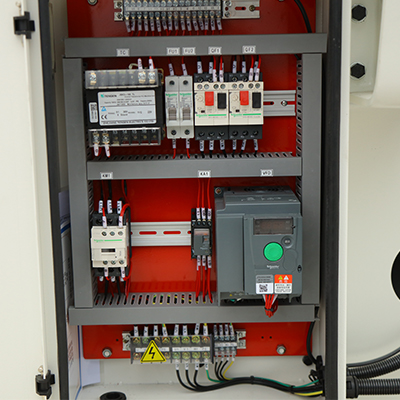

Electrodomésticos profesionales

Los productos y electrodomésticos de Siemens y Schneider aseguran que toda la máquina funcione bien con un rendimiento estable

Mesa de alimentación cromada de hierro fundido

Toda la mesa de alimentación cromada de hierro fundido es la normalización tratada térmicamente para la máxima estabilidad. Mesa de coeficiente & El ajuste de la valla se realiza rápidamente mediante una palancas rápidas.