50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Caractéristiques | QMJ145H | QMJ143S | QMJ143E | QMJ143F | |

|---|---|---|---|---|---|

| Max.. largeur de travail | MM | 500 | 300 | 300 | 300 |

| Épaisseur de travail | MM | 10-170 | 10-85 | 10-120 | 10-120 |

| Min. durée de travail | MM | 740 | 530/200 | 600/300 | 585/300 |

| Saw spindle dia. | MM | φ60 | φ55 | φ55 | φ55 |

| Reducing sleeve dia. | MM | φ80 | φ70 | φ70 | φ70 |

| Saw spindle speed | r / min | 2600 | 4000 | 4000 | 4000 |

| Vitesse d'alimentation | m / mon | 3-24 | 4-30 | 4-30 | 4-30 |

| Puissance totale | KW / HP | 81.25/109 | 32.57/43.5 | 39.57/52.7 | 39.57/52.7 |

| Diamètre de la hottes. | MM | 2*φ150 | 2*φ150 | 2*φ150 | 2*φ150 |

| Dimensions globales | MM | 4850*2020*1880 | 1930*1580*1560 | 2200*1500*1580 | 4460*1570*1600 |

| Poids | kg | 4250 | 2250 | 2300 | 2300 |

1. The worktable and body are made of high-quality castings as a whole, with stable performance and good precision.

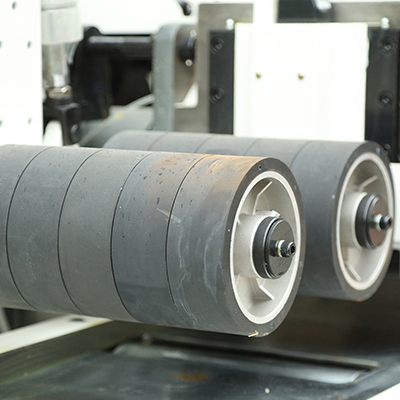

2. The main shaft is made of special materials and processed with special processing and dynamic balance. After precision assembly, it runs smoothly and has high precision.

3. The rolling box lifting system adopts electric lifting structure, which is convenient and quick to operate.

4. The feeding adopts frequency conversion speed regulation, and the feeding speed reaches 4-30m/min, which is suitable for wood processing requirements of various materials and thicknesses.

5. Equipped with upper and lower triple anti-reverse rebound device, the operation is safe and reliable.

6. Equipped with a fully enclosed safety shield, which is safe and environmentally friendly.

7. The worktable is equipped with front and rear active feeding rollers, which facilitates feeding and reduces labor intensity.

8. Optional laser reticle to achieve optimal operation.

Moteur personnalisé

Dans notre tableau des paramètres techniques de 4 Planeur de côté Moulder, Vous pouvez voir notre configuration standard. Si vous avez besoin, Nous pouvons mettre à niveau la puissance du moteur pour vous.

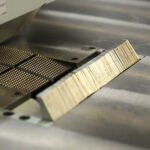

Saw Blade

La plupart de nos machines de menuiserie n'ont pas d'outils de coupe lors de l'exportation, Parce que différents usines de menuiserie ont besoin de types de coupeurs différents. Pour améliorer notre service, Nous pouvons vous aider à acheter des outils de coupe.

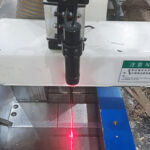

LASER GUIDE

For straight line rip saw and single-blade rip saw, customers will add laser guide for better cutting, cutting will be more accurate. The straight line will be more straight.

FONTE ENTIÈRE

Une pièce extra lourde, Le cadre de la machine en fonte est spécialement traité thermiquement pour une stabilité et une rigidité maximales grâce à la configuration standard.

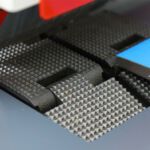

ANTI-REBOUND SAFETY DEVICE

The anti-rebound safety device located on the infeed ensures operational safety.

Wear resistance guide track

The casting guide track and chain plate are made of special materials, specially processed and precisely processed, with high surface hardness, high precision and good wear resistance

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

Dust Removal Brush

The dust removal brush made of special materials is matched with a quantitative oil injection device to clean and lubricate the chain plates in real time

HIGH PRECISION SPINDLE

All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy.

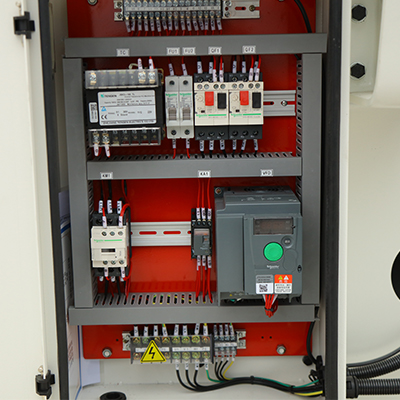

PROFESSIONAL ELECTRICAL APPLIANCES

Les produits et appareils électriques Siemens et Schneider garantissent le bon fonctionnement de l'ensemble de la machine avec des performances stables

CAST IRON CHROMED FEED TABLE

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.