Nom de produit: Double side planer QMB206GX

Application: double side planing, surface planing.

Largeur de travail: 630MM

Épaisseur de travail: 10-200MM

Max.. Cutting Depth: 5/3MM

Vitesse d'alimentation: 8-30m / mon

Function: woodworking machinery wood planer

50+ années d'expérience

3 Garantie des années

Support technologique 7 * 12h

standard et unifié

| Raboteuse double face | Unité | QMB206GZ | QMB206GX | QMB204GX |

|---|---|---|---|---|

| Max working width | MM | 630 | 630 | 445 |

| Max working thickness | MM | 200 | 200 | 200 |

| Min working thickness | MM | 8 | 10 | 10 |

| Min working length | MM | 315 | 315 | 315 |

| Max cutting depth per time(top cutter) | MM | 5 | 5 | 5 |

| Max cutting depth per time(bottom cutter) | MM | 3 | 3 | 3 |

| Vitesse d'alimentation(inverter) | m / mon | 8~30 | 8~30 | 8~30 |

| Cutter spindle speed | r / min | 5000 | 5000 | 5000 |

| Cutter spindle diameter | MM | φ130 | φ130 | φ130 |

| Knife size | MM | 15x15x2.5x6T, optional 30x12x1.5 | 15x15x2.5x6T, optional 30x12x1.5 | 15x15x2.5x6T, optional 30x12x1.5 |

| Dust outlet | MM | φ150×2 | φ150×2 | φ150×2 |

| Puissance totale | kW | 30.45 | 30.45 | 22.25 |

| Top spindle motor | kW | 15 | 15 | 11 |

| Bottom spindle motor | kW | 11 | 11 | 7.5 |

| Feeding motor | kW | 3.7 | 3.7 | 3 |

| Lifting motor | kW | 0.75 | 0.75 | 0.75 |

| Overall dimension(L×W×H) | cm | 277×155×172 | 277×155×172 | 283x145x180 |

| Poids | kg | 3000 | 3000 | 2700 |

1. This machine tool adopts an integral casting body, which has been treated with aging and has stable performance.

2. The working table is made of special wear-resistant material, which has sufficient rigidity and wear resistance.

3. The cutter shaft is precisely machined, dynamiquement équilibré, Et précisément assemblé, so it runs smoothly and has good precision.

4. The feeding adopts elastic pressing claw, the pressing strength is adjustable, the feeding is smooth, and the processing board surface quality is good.

5. The upper pressing and planing system adopts upper and lower driving rollers, and the feeding is strong and powerful.

6. The feeding adopts infinitely variable speed to ensure the quality of processing various wood products.

7. The lifting system adopts digital display, qui est intuitif et pratique à utiliser.

8. All electrical components and transmission parts are of high-quality brands and components, avec des performances stables.

9. Quick belt tension adjustment and quick planer replacement, easy to operate.

10. Configure the manual lubrication pump to lubricate the column slide plate to ensure the flexibility of lifting.

This double side planer is mainly in accordance with the needs of high-efficiency and mass production in the majority of solid wood furniture factories and various solid wood preparation processing enterprises, especially the needs of increased processing thickness.

We designed and developed a heavy-cutting double-sided woodworking planer according to the international advanced product structure and technology.

Double Side Planer QMB204G has the advantages of high production efficiency, good processing quality and stable performance. It is the ideal equipment for high-efficiency and mass production in the majority of solid wood furniture factories and various preparation processing enterprises.

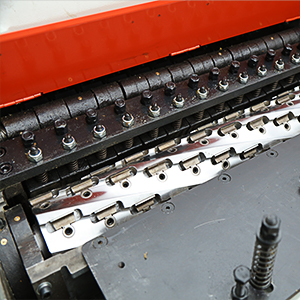

SPIRAL CUTTER

Our double side planer is equipped with spiral cutter helical cutter, which is much easier to operate and change the knife blade. No need to sharpen cutter.

Moteur personnalisé

In our technical parameter table of double side planer, Vous pouvez voir notre configuration standard. Si vous avez besoin, we can upgrade motor power of wood planer for you.

FONTE ENTIÈRE

Une pièce extra lourde, Le cadre de la machine en fonte est spécialement traité thermiquement pour une stabilité et une rigidité maximales grâce à la configuration standard.

HARD-CHROMED FEED TABLE

The entire Cast Iron – Chromed In-feed table is normalization heat treated for maximum stability. In-feed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.

SPIRAL (HELICAL) CUTTER

The upper and bottom cutter head are equipped with imported heavy-cutting spiral cutter, which have been dynamically balanced and equipped with international brand SKF bearings for precision assembly, avec des performances stables, good accuracy and good durability.

Well Laid-out pressure spikes

The pressure spikes are in an overlapped layout with a minimum of gaps that hold the workpiece firmly and evening ensuring shake-free feeding, even for short workpiece.

Digital positioning control

The thickness of cut can be controlled by a digital positioning control. Once the preset position is reached, the table elevation stops automatically.

INVERTER

Frequency control of feedingspeed. Adjust the feeding speed conveniently.

Gear reducer

Reduce wear caused by temperature rise and improve efficiency of power transmission.

PROFESSIONAL ELECTRICAL APPLIANCES

Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance.

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.