50+ años de experiencia

3 Garantía de años

Soporte técnico 7*12h

Estándar y unificado

| Presupuesto | QMJ153D | QMJ154D | QMJ164A | QMJ163S | |

|---|---|---|---|---|---|

| Máximo. sawing thickness | mm | 85 | 125 | 120 | 75 |

| Mínimo. sawing length | mm | 330 | 300 | 120/250 | 120/180 |

| Deep throat | mm | 460 | 510 | 660 | 510 |

| Saw shaft diameter | mm | Φ25.4 | Φ30 | φ50.8 | φ50.8 |

| Saw shaft speed | r/min | 4000 | 3450 | 3000 | 4000 |

| Velocidad de alimentación | m/mi | 12.5/16/19.5/24 | 8/13.6/19.1/24 | 5-24 | 5-26 |

| Potencia total del motor | KW/HP | 8.25/11 | 12.5/17 | 13.2/18 | 9/12 |

| Vacuum port diameter | mm | 2*φ100 | 2*φ100 | φ150+φ120 | φ150+φ120 |

| Dimensiones generales | mm | 1700*1100*1580 | 1960*1180*1600 | 2250*1680*1550 | 2000*1160*1380 |

| Peso | kg | 950 | 1150 | 1750 | 1350 |

This machine tool is a single-piece longitudinal sawing machine with a lower shaft type automatic feeding.

The structure of the pressing roller box and the length of the guide rail are lengthened to ensure the stability of the workpiece feeding and pressing.

The product track is a bilateral guide rail structure that can be adjusted unilaterally.

The maximum processing thickness is 75mm, and the shortest processing length is 120mm.

This product has accurate processing length, stable performance and better safety than the upper shaft type. It is mainly used for longitudinal cutting and trimming of wooden boards.

It is an ideal equipment for the majority of solid wood furniture factories, wood products factories and finger joint board processing industries.

motor personalizado

En nuestra tabla de parámetros técnicos de 4 Player de cepillador de lados, puedes ver nuestra configuración estándar. Si lo necesitas, Podemos actualizar la energía del motor para usted.

herramientas de corte

La mayoría de nuestra maquinaria de carpintería no tiene herramientas de corte cuando se exporta, Porque diferentes molinos de carpintería necesitan diferentes tipos de cortadores. Para mejorar nuestro servicio, Podemos ayudarlo a comprar herramientas de corte.

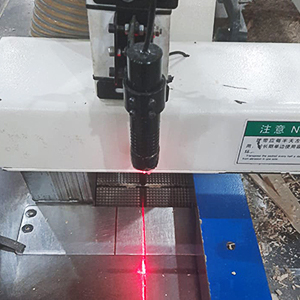

Laser Guide

Para sierra de rasgón recta y sierra de rasgón de hoja única, Los clientes agregarán guía láser para un mejor corte, El corte será más preciso. La línea recta será más recta.

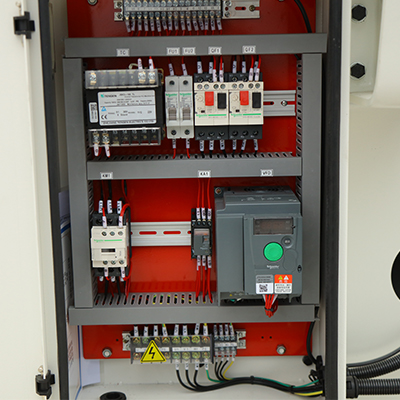

Siemens & Schneider elec

Los productos y electrodomésticos de Siemens y Schneider aseguran que toda la máquina funcione bien con un rendimiento estable.

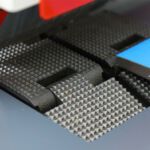

ANTI-REBOUND SAFETY

El dispositivo de seguridad antigüense ubicado en la información garantiza la seguridad operativa..

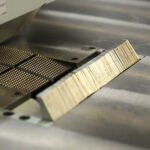

durable guide track

La pista de la guía de fundición y la placa de cadena están hechas de materiales especiales., especialmente procesado y procesado con precisión, con alta dureza superficial, Alta precisión y buena resistencia al desgaste.

Lubricador automático

El lubricador automático ofrece aceite de lubricación frecuente a la cadena de oruga.

Cepillo de eliminación de polvo

El cepillo de extracción de polvo hecho de materiales especiales se combina con un dispositivo de inyección de aceite cuantitativo para limpiar y lubricar las placas de cadena en tiempo real.

Guide Rail

The guide card board is equipped under the guide rail, which can effectively prevent the chain plate from clamping materials and damage the chain plate and saw blade by lifting, making it safer to use.