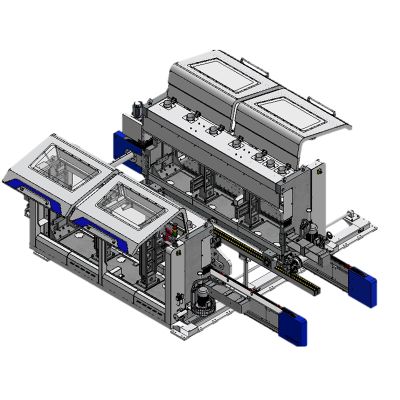

CNC Tenoner and Mortise Machine

Double end tenoner, CNC Tenoning and mortising machine are perfect for wood furniture industry, which can make different shapes of wood tenon and mortise.

Instead of manual tenoning and mortising machine, CNC tenoner and mortiser machine can process wood tenon and mortise with higher productivity and higher quality.

CNC tenoner and mortise machine can be used in various solid wood furniture factory, such as dining table and chair. Workable for different types of horizontal tenon, oblique tenon, plane oblique tenon, solid oblique tenon and roundness tenon, dovetails.

Get a FREE consultation!

featured machine of tenoning & mortising machine

double end tenoning machine

Name:

Category:

Application:

Functions:

Double end tenoner

CNC woodworking machine

Wooden door, calcium silicate board etc.

Double end squaring, tenoning, groove, T&G etc.

Table of Contents

Automatic CNC Tenoning and Mortising Machine Manufacturer

As a professional manufacturer of woodworking machinery, as for function of tenoning and mortising, we have different types of tenoning and mortising machine. Double end tenoner / tenoning machine to produce wooden door, wooden flooring, or for edge squaring. We are few of China Double End Tenoner Manufacturers. A double end tenoner is a CNC machine for edge processing, often referred to as a DET machine. It is a sophisticated machinery that is used to shape the sides of solid wood or chipboard panels, block board panels, or door panels.

What’s the function of a double end tenoner?

To produce the highly quality furniture, the best choice must be DET SERIES – DOUBLE END TENONER. It could deal properly with all kinds of furniture, such as solid wood products and panel furniture. Not only for cutting prefer size for double sides of panel, profile moulding and sanding, but also making the angular or tongue & groove according to your demand. All fully automatic functions can provide the most efficient capacities. The CNC double end tenoner machine is used widely in mass-production facilities for the creation of furniture, because it can produce large amounts of wood or chipboard quickly and cost-effectively. Whether in flooring production or for the manufacturing of furniture, windows, doors, fronts, panels and components – our double end tenoner / sizing machines create perfect profile quality.

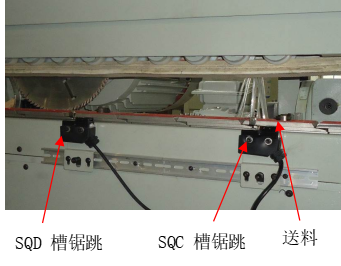

How to process panels by double end tenoner?

Double end tenoner tenoning machine are able to deal with transverse and longitudinal profiling with ease. Individual workpieces travel through the processing stages on a chain conveyor. Wooden panels are placed onto the conveyor and held in place with downwards pressure. As the panels pass through the two milling units of a DET machine, they are cut to the desired shape. Modern double end tenoners are able to cut different shapes into each side of a panel at the same time. The entire process takes just a few seconds, and thanks to automatic start and automated feeding, several panels can be processed in a very short space of time.

What are the applications of a double end tenoner machine?

1.WOOD-BASED PANELS: QCM double end tenoner are perfect solution for trimming and cross cutting, production of T&G profiling (tongue and groove) of panels from PB (particle board), MDF, OSB, plywood, and solid wood. To save the labor cost for you, we can make an full automatic production line for tongue and grrove production, combination of an automatic feeding system, two double end tenoner and automatic stacking system.

2.GYPSUM/FIBER/CEMENT: Boards for Construction

Double end tenoner machine can be used for processing heavy board with high density, such as cement bonded particle,fibre cement, mineral fibre, glas compound boards,gypsum fibre and calcium silicate board. One of the market leader Etex Group. They have purchased two 8 spindles double end tenoner from us, in order to replace their old double end tenoner SCM celaschi. These two double end tenonerare performing well. Their calcium silicate board is so heavy, up to 1,350kg/m3. Our double end tenoner machine are very suitable for a perfect cutting result and high quality edges.

Except above products, double end tenoner can also be used for following applications: FURNITURE PARTS: Solid wood, rear panels, drawer parts

COMPOSITE MATERIAL: HPL, compressed laminated wood, Aluminium/plastics

CONCRETE FORMWORK: Formwork beams and shuttering panels

WOODEN DOORS: Edge squaring and processing with double end tenoner

WALL PANELS/PARQUET: Cross processing with double end tenoner

How To Change Cutters for double end tenoner machine?

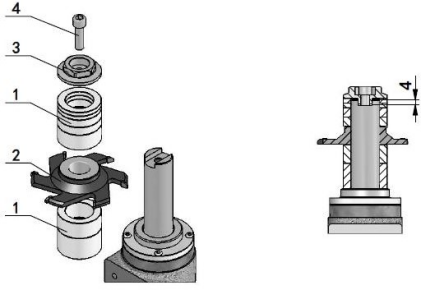

1. Installation of milling tools

Determine the quantity and thickness of rings 1.

Clean the plane of action of tools and spindles. Apply oil to the rings, safety rings and spindle nuts to prevent them from corrosion.

Install the tool step by step : ring 1, cutter 2 , rings 1 ,safety ring 3 and compression screw 4 in turn. Tighten the compression screw 4 by special double head wrench and make sure it could not loosen by itself.

Rotate the spindle by hand and make sure it runs freely.

To dismount the tool, the above procedures shall be performed in inverted sequence.

Note: The safety ring must fit into the slot of the spindle for at least 4 mm, so that the tool could be tightened axially and will not be over distorted.

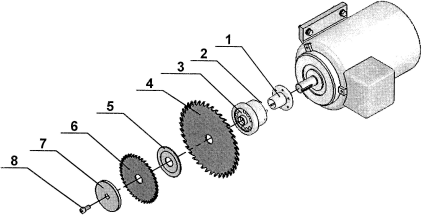

2. Installation of saw blades

Clean the plane of action of tools,spindles and pressure plate.

Install these in turn: expanding sleev 1, saw blade flange 3, tightening screws 2-fix the saw blade flange 3 on the motor shaft(be set well before delivery),then place the saw blade 4, saw blade spacer 5, saw blade 6(if need), pressure plate 7, Compression screw 8. Use special spanner lock the expanding sleeve 1, tighten the compression screws 8 with allen wrench, make sure they won’t loose by themselves.

Check if the spindle run freely in idle by rotating it with hand.

Use the knife shaft axial adjusting device for further accurate positioning, when machine is debugged.

Note: While installing the saw blades, make sure the direction of the saw teeth is in accordance with the rotating direction of the spindle.

When use saw blade, must use a safety protection device in strict accordance with the safety requirements.

3. Adjustment of saw shaft

The slotting cutter1 is installed on the first bottom spindle for producing a reference plane from the bottom on the right side of the work piece. It is tightened by the planing cutter 2 in the axial direction. The installation steps: install the slotting cutter, planing cutter, ring, safety ring and spindle nut in turn, and tighten the spindle nut with the special combination wrench, so that it does not loosen by itself. Then turn the spindle by hand and make sure it runs freely.

4. Adjustment of Milling unit

The milling unit is can be adjusted up/down, forward/backward and tilted. There are numerical readouts for the up/downwards and forwards/backwards adjustment and scales for the tilting adjustment. Milling shaft diameter is 40 mm, can do clockwise cutting or contra clockwise cutting . Before start machine to work, user must select the rotating direction of milling spindle and install the cutters with the corresponding direction and lock cutters well.

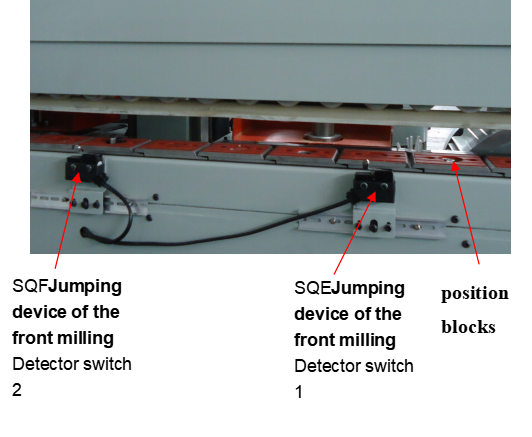

The front milling cutter can jump cut. The stretch out and draw back degree of milling cutter’s cylinder can be controlled by adjusting the height of the stop bolt.

What are the functions of each spindle of double end tenoner?

In order to make best use of our double end tenoner machine, we provide a professional solution for the cutters for each spindle. It is based on our rich experience of serving our customers.

First spindle: scoring. Normally one diamond saw blade will be ok.

Second spindle: hogging, better to use diamond cutter.

Third spindle: milling, you can put a profile cutter to make groove, profiling or what shape you need.

Forth spindle: milling, you can put a planing cutter to make a fine planing effect.

FAQ of Double end tenoner

1. do you have a double end tenoner with 3000mm?

yes, 3000mm is available.

2. can your double end tenoner process calcium silicate board and calcium silicate board?

yes, our double end tenoner can process heavy board, such as calcium silicate board and cement boards. We recommend you our 8 spindles double end tenoner, and select diamond cutting tools.

Our quality is your success. Our goal is to support you with our best woodworking machines and solutions. Woodworking machine is the most important investment for your wood processing factory. Our machine can save labor cost and bring higher productivity with higher quality, more automatic and accurate.