If you are looking for wood machine for your balsa wood processing, you can contact us.

Balsa wood is famous wood species in Ecuador. Balsa is a self-generating species in Ecuador, which means that it renews itself quickly without any risk of depletion.

Balsa is the only structural core material made of a natural, renewable resource. The balsa tree grows fast, has low to medium density, and best-in-class weight-specific mechanical properties. It is the first carbon neutral core material in the world.

Balsa wood is suitable for wind energy, marine, transportation, industrial and other applications. The composite can be produced using hand layup, pultrusion, infusion, pressed moulding, etc.

China have imported a lot of balsa wood mateial for processing core of the fan in wind industry.

After being cut, the balsa wood is kiln dried. This process ensures dimensional stability of the wood. Strict moisture controls through out the manufacturing is a must to ensure the required moisture content in final products.

Use double side planer for planing surface; then table rip saw will be used for trimming, to make straight line; then use glue and press machine to make balsa blocks.

You can sell balsa blocks directly, or you can buy more other machines to make further processing to make glued blocks into balsa panels. Then double end tenoning machine, sanding machine, slotting machine will be needed.

1. Double side planer

After rough processing by band saw or multiple rip saw, use double side planer to make the thickness and make surface more flat before next step. QMB206G or QMB204G will be your good choice, based on your need for processing width. Spiral cutter head for double side planer is what we recommend,

2. Trimming saw

After cutting by multi rip saw or band saw, the board is not so straight, then you need to use trimming saw single chip rip saw to make it more straight. QMJ164A is popular for trimming saw, it has a bottom spindle. Compared with a top spindle rip saw, QMJ164A can get a higher precision and higher productivity, and operation is more safe. For price reason, and if you don't need such a higher precision for the first step, QMJ154D or QMJ153D will be also good choice.

3. Double end tenoning

Double end tenoner machine provide a compact and flexible solutions for longitudinal and crosswise profiling for quality squaring offers the high processing accuracy and reliability of high performance. Our double end tenoners has an unbeatable price-quality ratio. Only few woodworking machine manufaturers can produce such kind of high standard double end tenoning machine.

SPIRAL CUTTER

You can select spiral cutter head or ordinary cutter head for double side planer. Spriral cutter is more recommended.

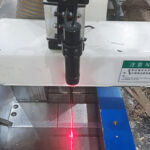

laser

Laser can be selected to help your production, which can make your cutting more straight with higher precision.

customized motor

Our regular motor is 380v, 50hz; Motor can be customized according to your requirement.

saw blade

Our single chip rip saw has one piece of saw blade as standard configuration. You can buy more to save transport cost.