50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | SFR-R1300V | SFR-R700V | SFR-R1300D | |

|---|---|---|---|---|

| Sanding cutting width | mm | 1300 | 700 | 1300 |

| Sanding cutting thickness | mm | 3-100 | 3-160 | 3-160 |

| The shortest sand cutting length | mm | 300 | 300 | 330 |

| Feeding speed | m/min | 3-20 | 0-24 | 5-30 |

| The first sanding spindle dia. | mm | φ215 | φ215 | 300 |

| The seconde sanding spindle dia. | mm | φ215 | φ215 | 300 |

| Total motor power | kW/HP | 29.17/39 | 21.47/29 | 38.67/52 |

| Sanding belt size | mm | 2100*1370 | 770*2100 | 1340*2200 |

| Vacuum port dia. | mm | 3*φ180/3*φ150 | 2*φ180/3*φ150 | 3*φ180/3*φ150 |

| Machine dimensions | mm | 2120*2080*2300 | 2050*1510*2300 | 2520*2130*2350 |

| Machine weight | kg | 3800 | 2950 | 4700 |

This product is mainly based on the needs of fine sanding in the furniture manufacturing industry. It is a floating primer sanding machine. The characteristics are that the worktable is fixed, the sand frame parts are adjusted by numerical control, and the speed of the sand belt is frequency-controlled. It has the advantages of high sand cutting precision and high efficiency. It is mainly used for primer grinding and pre-processing of materials (sanding before painting), and can also be used for assembly line production on NV and UV painting, which can greatly improve work efficiency.

1. The sand frame has the function of jogging and lifting, which can be lifted by 0.1mm each time, and is equipped with a numerical control thickness determination system, which is operated by button, with high precision and convenient and fast operation.

2. The sand cutting speed adopts frequency conversion speed regulation, and the sand cutting direction can be reversed.

3. The rear and upper part of each sanding part are equipped with electric swing air blowing and abrasive belt cleaning and dust removal devices.

4. The worktable is a fixed structure and is equipped with a vacuum adsorption device, which can effectively solve the warping phenomenon of thin plate processing.

5. Optional configuration: According to the high quality requirements of the sanding surface, the second sand frame is equipped with imported 3M polishing rollers, the quality is refined and the quality is exquisite, and you can enjoy the excellent paint effect. Model: SFR-G700V.

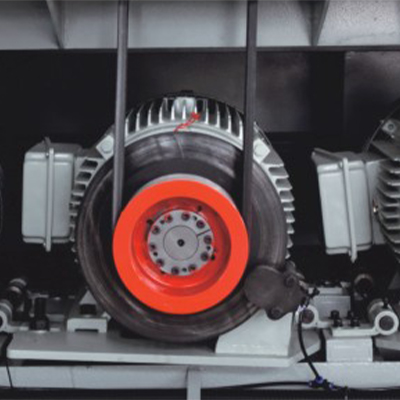

customized Motor

In our technical parameter table of sanding machine, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine sanding machines for you with automatic in-feeding and out-feeding system.

inside setted motors

Motors for coarse sanding, semi-fine sanding, fine sanding are inside setted , to make cleaning appearance.

anti-reversal roller

The second group of idler rollers is anti- reversal roller, to protect the safety of the operator.

casting plates

The support plates are made of high quality casting, which makes our machine more stable and high accuracy.

Double pressure roller

Double pressure roller structure to ensure seady and smooth feeding.

stablly and precisely

SPR-RP series configured with precision spiral planing cutter module, and in keyboard type sectional pressuring structure. It’s can plan and sanding at the same time, stablly and precisely.

8 sets feeding rollers

SRR630S type is equipped with 8 sets feeding rollers, 3 front, 2 in middle, 3 rear. So it can apply to materails over 230mm length.