50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | MJ263H | MJ262F | MJ263G | MJ264C | |

|---|---|---|---|---|---|

| Max. working width | mm | 300 | 200 | 300 | 450 |

| Working thickness | mm | 10-180 | 10-150 | 150-280 | 40-70 |

| Min. working length (single/continuous) | mm | 635/450 | 635/450 | 800 | 600 |

| Saw spindle dia. | mm | φ50 | φ40 | φ60 | φ60 |

| Saw spindle speed | r/min | 4000 | 4500 | 3000 | 4500 |

| Feeding speed | m/min | 4-18 | 4-16 | 3-15 | 6-24 |

| Total power | kW/HP | 645.5/86 | 48.5/65 | 94.75/127 | 64.75/87 |

| Suction hood dia. | mm | 3*φ150 | 3*φ140 | 4*φ140 | 42*φ140 |

| Overall dimensions | mm | 2950*1620*1770 | 2880*1320*1730 | 3550*1450*1800 | 2850*1580*1620 |

| Weight | kg | 3300 | 2500 | 3500 | 2800 |

This product is mainly used for multi-piece longitudinal cutting operations of wood processed by fixed thickness.

It adopts upper and lower cutting and small sawing path. Ideal equipment.

This product is mainly based on the needs of the lumber industry for multi-blade sawing and processing of large square materials, a newly developed wet material processing, heightened upper and lower multi-blade sawing product.

The product adopts the middle position to cancel the worktable, and configures the upper and lower active feeding roller structure, which has the advantages of smooth feeding, smooth chip removal and good processing quality.

It is an ideal equipment for high efficiency, energy saving and material saving in the solid wood processing and timber industry processing large boards and thick boards.

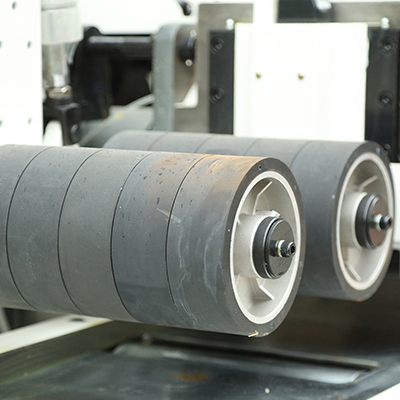

1. The machine tool adopts two sets of upper and lower saw blades for simultaneous sawing, and the middle part is equipped with an upper and lower active feeding roller structure, which has the advantages of smooth chip removal, stable feeding, high processing material rate and good processing quality.

2. There are 7 sets of active feeding rollers in the top, 4 and 3 at the back, and 5 sets of active feeding rollers and 2 sets of passive rollers in the bottom, front 3 and 4, to achieve strong feeding and ensure the smoothness of feeding.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Saw Blade

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

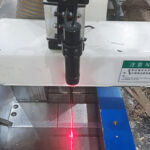

LASER GUIDE

For straight line rip saw and single-blade rip saw, customers will add laser guide for better cutting, cutting will be more accurate. The straight line will be more straight.

ENTIRE CAST IRON

Extra heavy one-piece, cast Iron machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

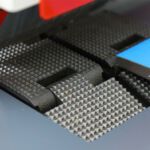

ANTI-REBOUND SAFETY DEVICE

The anti-rebound safety device located on the infeed ensures operational safety.

Wear resistance guide track

The casting guide track and chain plate are made of special materials, specially processed and precisely processed, with high surface hardness, high precision and good wear resistance

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

Dust Removal Brush

The dust removal brush made of special materials is matched with a quantitative oil injection device to clean and lubricate the chain plates in real time

HIGH PRECISION SPINDLE

All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy.

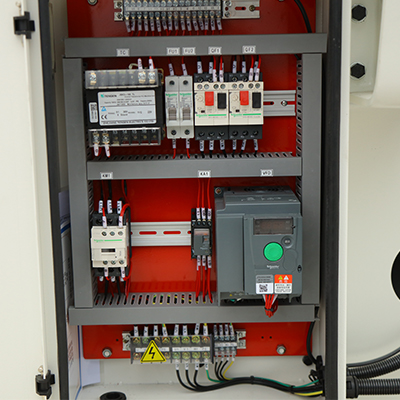

PROFESSIONAL ELECTRICAL APPLIANCES

Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance

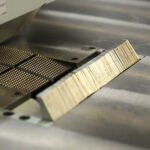

CAST IRON CHROMED FEED TABLE

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.