50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | QMJ153D | QMJ154D | QMJ164A | QMJ163S | |

|---|---|---|---|---|---|

| Max. sawing thickness | mm | 85 | 125 | 120 | 75 |

| Min. sawing length | mm | 330 | 300 | 120/250 | 120/180 |

| Deep throat | mm | 460 | 510 | 660 | 510 |

| Saw shaft diameter | mm | φ25.4 | φ30 | φ50.8 | φ50.8 |

| Saw shaft speed | r/min | 4000 | 3450 | 3000 | 4000 |

| Feeding speed | m/min | 12.5/16/19.5/24 | 8/13.6/19.1/24 | 5-24 | 5-26 |

| Total motor power | kW/HP | 8.25/11 | 12.5/17 | 13.2/18 | 9/12 |

| Vacuum port diameter | mm | 2*φ100 | 2*φ100 | φ150+φ120 | φ150+φ120 |

| Overall dimensions | mm | 1700*1100*1580 | 1960*1180*1600 | 2250*1680*1550 | 2000*1160*1380 |

| Weight | kg | 950 | 1150 | 1750 | 1350 |

1. The machine body of straight line rip saw is casting machine body with special technology, special treatment, precision processing, stable performance and good precision.

2. The main shaft is made of special materials, after precision machining, dynamic balance treatment and precision assembly, it runs smoothly and has good accuracy.

3. The specially designed bilateral leaning rule is convenient for users to exchange and use, and prevents the long-term unilateral use of the chain track from affecting the machining accuracy of the machine tool.

4. Equipped with a microcomputer automatic oiling pump to lubricate the guide rails regularly, fixedly and quantitatively to ensure the normal use and life of the machine.

5. QMJ164A can be equipped with a built-in idler on the worktable, which is convenient for processing and material return.

6. -T type is optional configuration, and the roller box adopts electric lifting control, which is convenient and quick to operate.

Straight line rip saw, single-chip rip saw, single -blade rip saw, are used for trimming the board, and making the straight line. Only when you can get a straight line, your processing will be more accurate.

If you need straight line rip saw, both top spindle rip saw and bottom rip saw are good choice.

The main function for straight line rip saw is to make trimming for the wood board, and get a very straight line.

We have different type of single blade single chip rip saw straight line rip saw, working width from 75mm to 125mm.

And we have top spindle and bottom spindle straight line rip saw.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

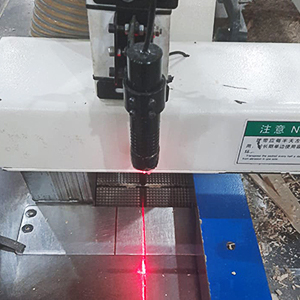

Laser Guide

For straight line rip saw and single-blade rip saw, customers will add laser guide for better cutting, cutting will be more accurate. The straight line will be more straight.

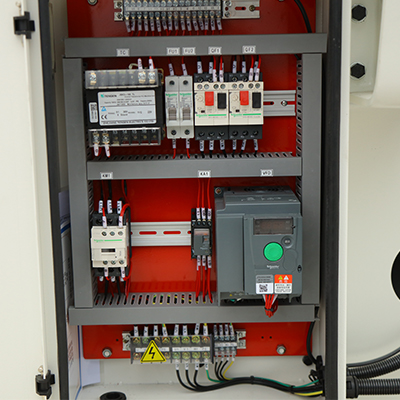

Siemens & Schneider elec

Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance.

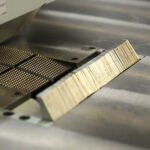

ANTI-REBOUND SAFETY

The anti-rebound safety device located on the infeed ensures operational safety.

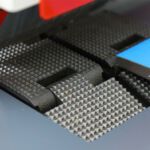

durable guide track

The casting guide track and chain plate are made of special materials, specially processed and precisely processed, with high surface hardness, high precision and good wear resistance.

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

Dust Removal Brush

The dust removal brush made of special materials is matched with a quantitative oil injection device to clean and lubricate the chain plates in real time.

Guide Rail

The guide card board is equipped under the guide rail, which can effectively prevent the chain plate from clamping materials and damage the chain plate and saw blade by lifting, making it safer to use.