50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | SPR-RP1300 | SRRP1300C | SRP1300B | SRP630S | |

|---|---|---|---|---|---|

| Sanding cutting width | mm | 40-1300 | 40-1300 | 40-1300 | 40-630 |

| Sanding cutting thickness | mm | 3-120 | 3-120 | 3-160 | 3-180 |

| The shortest sand cutting length | mm | 520 | 500 | 620 | 230 |

| Planer shaft speed | m/s | 36 | / | / | / |

| Speed of the first group of sanding belt | m/s | 19 | 21 | 19 | 19 |

| Speed of the first group of sanding belt | m/s | 18.5 | 19 | 18 | 16 |

| Speed of the third group of sanding belt | m/s | / | 18.5 | / | / |

| Feeding speed | m/min | 6-30 | 6-30 | 6-30 | 6-30 |

| Sanding belt size | mm | 1330*2200 | 1330*2200 | 1330*2200 | 650*2100 |

| Total motor power | kW/HP | 77.12/103 | 95.62/128 | 57.12/77 | 20.74/28 |

| Vacuum port of dia. | mm | 9*φ150 | 7*φ150 | 5*φ150 | 5*φ150 |

| Machine dimensions | mm | 2850*2050*2200 | 2800*2040*2200 | 2260*2060*2230 | 2120*1270*2050 |

| Machine weight | kg | 5150 | 5050 | 3700 | 1900 |

The wide belts sanding machine SRRP630S is specially developed for the sanding short wood piece. SRP630S type is equipped with 8 sets feeding rollers, 3 front, 2 in middle, 3 rear. So it can apply to materails over 230mm length.

1. The beam support of this machine tool adopts high-quality castings, which has good shock absorption, stable performance and good precision.

2. The worktable is welded with thick steel plate and large angle steel, and has been treated with special stress relief and precision machining. Its performance is stable and durable.

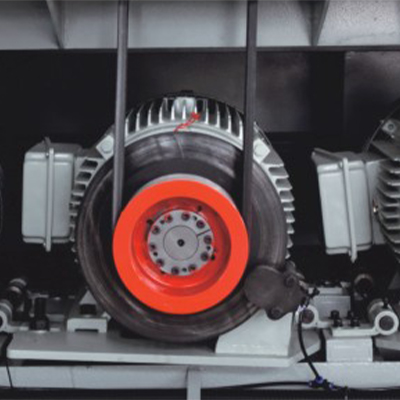

3. The motor for coarse sand and fine sand of the machine tool adopts built-in structure, which has the advantages of compact structure and beautiful appearance.

4. Coarse sand roller adopts large-diameter steel roller on the rear wall, which is processed by precision machining and dynamic balance, and has strong cutting and stable performance.

5. The fine sand rubber roller adopts high-quality rubber roller, equipped with imported polishing pad, and the quality of the sanding board is smooth and straight.

customized Motor

In our technical parameter table of sanding machine, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine sanding machines for you with automatic in-feeding and out-feeding system.

inside setted motors

Motors for coarse sanding, semi-fine sanding, fine sanding are inside setted , to make cleaning appearance.

anti-reversal roller

The second group of idler rollers is anti- reversal roller, to protect the safety of the operator.

casting plates

The support plates are made of high quality casting, which makes our machine more stable and high accuracy.

Double pressure roller

Double pressure roller structure to ensure seady and smooth feeding.

stablly and precisely

SPR-RP series configured with precision spiral planing cutter module, and in keyboard type sectional pressuring structure. It’s can plan and sanding at the same time, stablly and precisely.

8 sets feeding rollers

SRR630S type is equipped with 8 sets feeding rollers, 3 front, 2 in middle, 3 rear. So it can apply to materails over 230mm length.