50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | ML9620HM | ML9620M | ML9620SMF | ML9616SM | |

|---|---|---|---|---|---|

| Working width | mm | 20-200 | 20-200 | 20-200 | 35-160 |

| Working thickness | mm | 10-200 | 10-125 | 10-120 | 15-120 |

| Min. working length | mm | 550/480 | 650/480 | 650/480 | 650/480 |

| Saw spindle Dia. | mm | φ50 | φ40 | φ50 | φ50 |

| Saw spindle speed | r/min | 4500 | 4500 | 4000 | 4000 |

| Planer spindle dia. | mm | φ40 | φ40 | φ40 | φ40 |

| Planer spindle speed | r/min | 6800 | 6800 | 6800 | 6800/8000 |

| Feeding speed | m/min | 5-25 | 5-25 | 6-30 | 6-30 |

| Total power | kW/HP | 94.5/126 | 82.25/110 | 72.75/97 | 58.25/80 |

| Suction hood dia. | mm | 3*φ150+4*φ120 | 3*φ150+4*φ120 | 6*φ150 | 2*φ150+4*φ120 |

| Overall dimension | mm | 4580*1800*1750 | 4530*1680*1630 | 4420*1790*1750 | 4170*1530*1720 |

| Weight | kg | 4600 | 4300 | 4850 | 3750 |

1. The saw blade can be installed directly on the saw shaft. The saw blade adopts a small diameter and a thin saw path to save material.

2. The left and right vertical shafts are heightened, and the maximum processing height is 200mm to meet the processing of wooden beams and wooden houses.

3. Electric lifting structure, easy to operate.

4. Increase the power of the motor to meet the processing requirements of large square material planing and multi-blade sawing.

5. The pressure plate in front of the upper knife adopts a cylinder pressing material structure to improve the smoothness of feeding.

6. Equipped with automatic air jet, water jet or oil jet device as standard to dissipate heat and cool the saw blade, improve the service life of the saw blade and the quality of the processed parts.

Professional solution for large-scale square material process in the anti-corrosion wood processing industry and the wood beam and wooden house processing industry. This planing and sawing machine combinds four-sided moulder and up-down saw. It’s firstly plan four sides of large square materials, and then sawing up and down into pieces. It has high production efficiency and saves materials. Equipped with automatic air jet, water jet or oil jet device as standard to cool the saw blade, improve the service life of the saw blade and the quality of the processed parts.

customized trimming cutter

The in-feeding table of our 4 side planer moulder can be lengthened, customized length according to your requirements.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

saw blade

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

ENTIRE CAST IRON

Extra heavy one-piece, cast Iron machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

ANTI-REBOUND SAFETY DEVICE

The anti-rebound safety device located on the infeed ensures operational safety.

Wear resistance guide track

The casting guide track and chain plate are made of special materials, specially processed and precisely processed, with high surface hardness, high precision and good wear resistance

Automatic lubricator

The automatic lubricator delivers frequent lubrication oil to the caterpillar chain.

Dust Removal Brush

The dust removal brush made of special materials is matched with a quantitative oil injection device to clean and lubricate the chain plates in real time

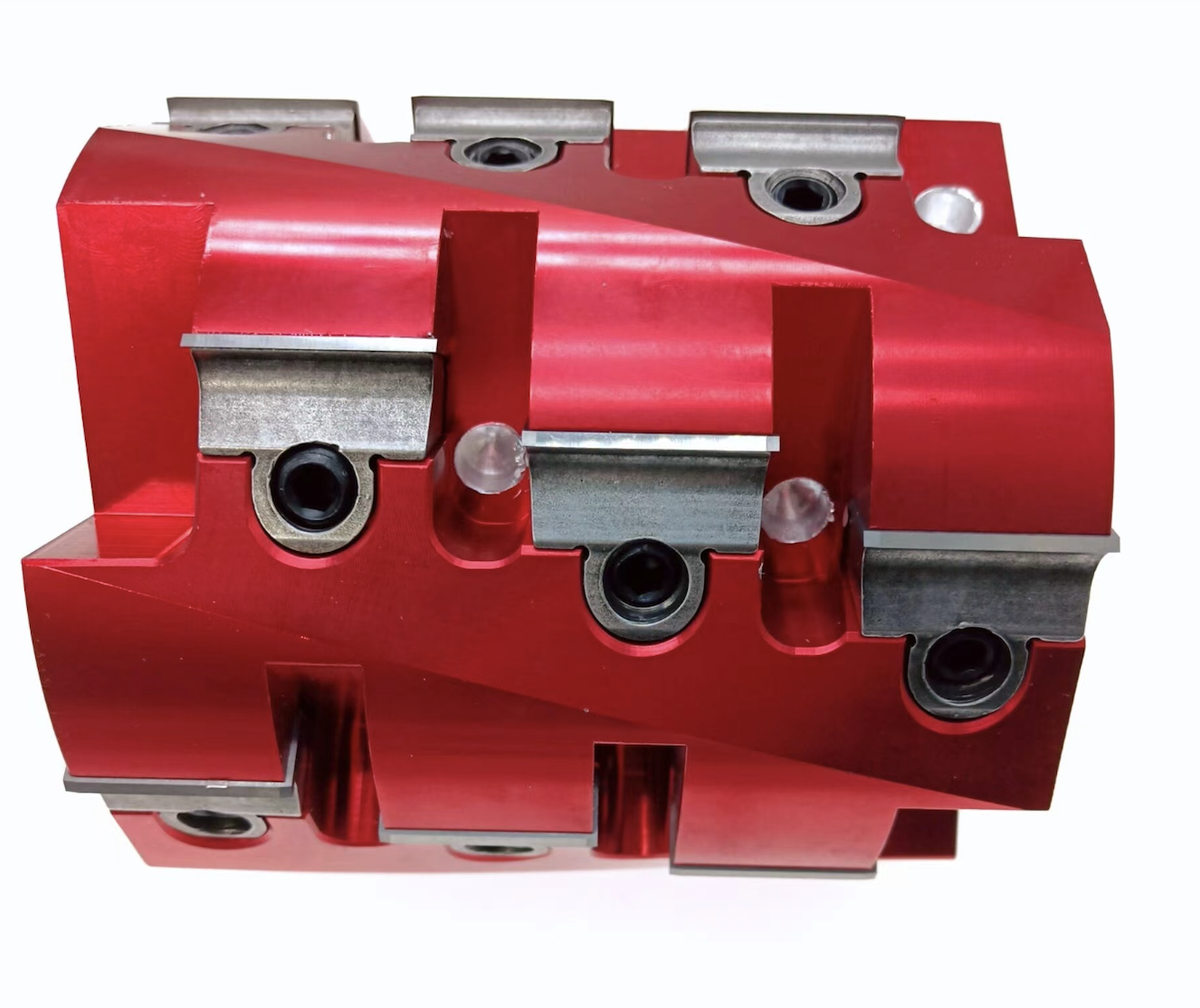

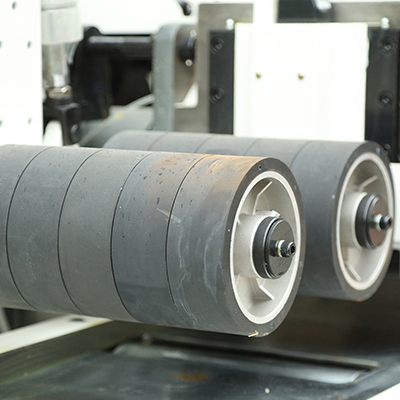

HIGH PRECISION SPINDLE

All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy.

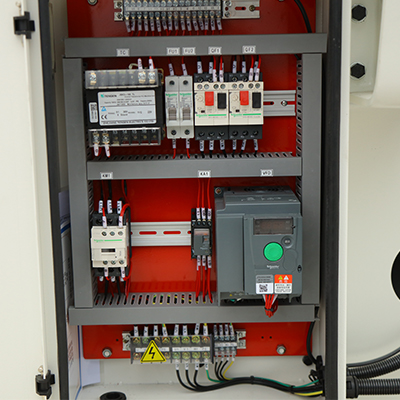

PROFESSIONAL ELECTRICAL APPLIANCES

Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance

CAST IRON CHROMED FEED TABLE

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.