50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | MX3815C-K | |

|---|---|---|

| Max. working size of square tenon (horizontal) | mm | 140*80 |

| Max. working width vertical tenon | mm | 80 |

| Max. wroking dia. of circle tenon | mm | φ80 |

| Max. depth of tenon | mm | 70 |

| Spindle dia. | mm | φ30 |

| Spindle speed | r/min | 8500 |

| Main motor power | kW/HP | 3/4 |

| X-axis motor power | kW/HP | 1/1.5 |

| Y- axis motor power | kW/HP | 1/1.5 |

| Suction hood dia. | mm | φ120 |

| Overall dimensions | mm | 2150*1300*1780 |

| Weight | kg | 1000 |

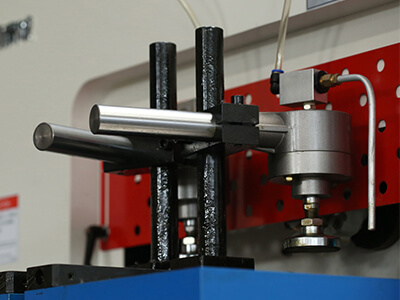

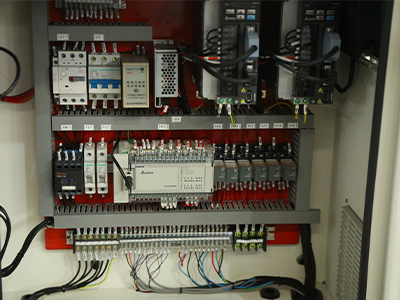

Both X and Y axes use imported ball screw linear guides, servo motors drive, and are equipped with full servo drive systems to achieve dual-axis linkage, with stable performance and good precision. Equipped with PLC+touch screen numerical control operating system, it has the advantages of simple, practical, convenient and quick operation.

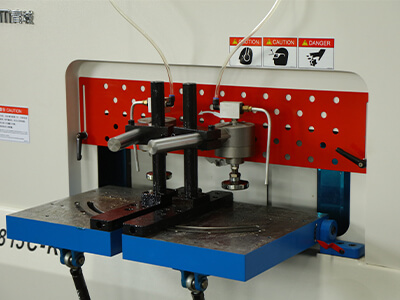

This upgraded CNC tenoning machine is mainly to meet the needs of solid wood processing users to improve processing efficiency and humanized operation. Can process round tenon, oval tenon, square tenon, oblique tenon.

Its maximum processing width is 140mm. The maximum processing thickness is 80mm. The maximum tenon depth is 70mm. It has high processing efficiency and simple operation. It is an ideal equipment for the majority of solid wood processing enterprises and processing customers in the dining table and chair industry to speed up and upgrade.

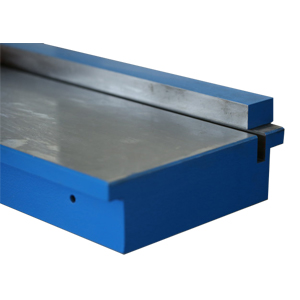

customized table

The in-feeding table of our 4 side planer moulder can be lengthened, customized length according to your requirements.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

Double working position, lead to high working efficient.

adopt import linear guide rail and ball crew, achieve two-spindle XY linkage, guaranteeing high working efficient and precision.

Adopt touch screen control, the operation is simple and easy to learn. Convenient and fast.

Siemens and Schneider electrial products and appliances insure the whole machine run well with a stable performance.