50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | QMX8025M | QMX6025M | QMX3826D*8 | QMX3820D | |

|---|---|---|---|---|---|

| Working width | mm | 300-2500 | 300-2500 | 300-2600 | 300-2000 |

| Working thickness | mm | 10-120 | 10-120 | 10-70 | 10-70 |

| Feeding block spacing | mm | 500 | 500 | 240 | 240 |

| Feeding speed | m/min | 6-36 | 6-36 | 5-20 | 5-20 |

| Saw shaft speed | r/min | 3000 | 3000 | 3000 | 3000 |

| Milling axis speed | r/min | 7500 | 7500 | 7000 | 7000 |

| Buckle milling spindle speed | r/min | / | / | 8000 | / |

| Total motor power | kW/HP | 47/64 | 41/56 | 26.06/35 | 20.95/28 |

| Vacuum port diameter | mm | 8*φ120 | 6*φ120 | 8*φ100 | 6*φ100 |

| Machine dimensions | mm | 4880*4650*1900 | 4880*4130*1890 | 4700*3350*1600 | 4100*2500*1460 |

| Weight | kg | 6500 | 6000 | 4300 | 3250 |

1. The machine body and its bed are integrally cast with high-quality castings, which are specially processed and precisely processed by the five-sided gantry machining center, with stable performance, good rigidity and high precision. .

2. The main shaft adopts special materials, after special treatment, precision processing and assembly, the speed of the milling cutter is 7000r/min and the speed of the buckle shaft is 8000r/min, which has the advantages of stable operation and good processing quality.

3. The feeding adopts high-precision synchronous track connection and round bar guide rail guide structure to ensure stable operation, accurate positioning and good processing quality.

4. The fixed width system adopts imported linear guide rail and ball screw drive, and is equipped with a fixed protective cover to overcome the previous phenomenon of wood chip dust blocking the guide rail and ensure the precise width of the fixed width system.

5. The workbench panel is made of special wear-resistant synthetic material, which runs smoothly, has good processing quality and greatly improves wear resistance.

6. The selected feeding system is equipped with a hard-tooth surface reducer and an imported frequency converter to realize variable-frequency feeding. The feeding speed can reach 5-20m/min. The operation is convenient and fast, and it is suitable for processing various materials.

7. The material pressing beam adopts double-column material pressing structure and electric lifting structure to ensure stable material pressing, guarantee the quality of processed products, and the operation is convenient and quick.

Mainly used for milling and tenoning processing of solid wood flooring, engineered flooring, and laminate flooring double-end trimming machine. It is the ideal equipment for upgrading and upgrading of the majority of users in the floor processing industry.

Double end tenoner QMX3826D and QMX3820D are mainly designed and developed according to the needs of floor processing in the solid wood flooring and engineered wood floor processing industries. The front is up and down sawing, the middle milling shaft, and the back is double-end milling product with a universal milling shaft. The maximum processing width is 2600mm and the maximum processing thickness is 70mm, which can effectively meet the processing of snap tenons that cannot be completed by the six-axis floor double-end milling tenon.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

ENTIRE CAST IRON

Extra heavy one-piece, cast Iron machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

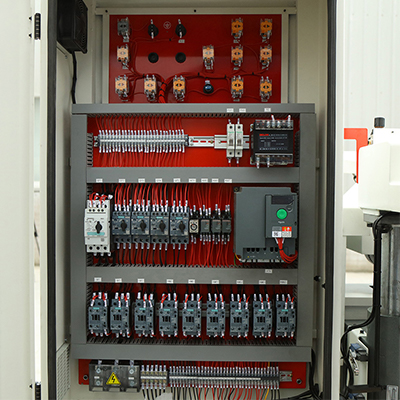

SIEMENS ELECTRICAL

Siemens and Schneider electrical products and appliances insure the whole machine run well with a stable performance

SYNCHRONOUS MOVEMENT

Worktable width movements uses imported linear guide and CNC automatic width setting structure which has feature of easy adjustment, precise positioning and excellent wear ability.

ADVANCED PLC CONTROL

The operating system is equipped with an imported computer touch screen and PLC for joint control, which is intuitive and convenient to operate, which can effectively reduce adjustment time and improve production efficiency.