Product Name: double-end Squaring, Milling & Sanding Machine QMXK1225JS

Application: door making, wooden flooring, for wooden furniture production and interior furnishings

Functions: squaring, trimming, sanding

Spindles: 6 Spindles

50+ years experience

3 years warranty

tech support 7*12H

standard and unified

This high-performance double-end tenoner can be configured as required to tackle a host of different tasks: angle cuts, bevel cuts, profiling, rabbeting, grooving, sanding and corner processing. Thanks to its robust design, low-wear technology and high level of availability, this double end tenoning machine machine is exactly the right choice for manufacturing doors, fronts and panels.

• User-friendly PLC control

• Width setting through touch-sensing screen for increased accuracy and convenience

• Moulding spindle is directly driven by a high-frequency motor, providing 7,500 rpm spindle speed

• Link chains are driven by a frequency-inverted motor, ensuring synchronized feed at both sides

• 6 and 8 spindles (optional)

Double end tenoner provides the best way to productivity and versatility

• The double end tenoner is designed and engineered for high quality wooden furniture with profitable production.

• They are ideal for producing solid wood and panel furniture and wooden doors.

• The series of double end tenoner provides various functions, such as double end sizing, profile moulding. It’s a highly automated machine that creates the efficiency you’ve come to expect.

customized processing width

The processing width of double end tenoning machine can be customized according to your requirements. 3000mm is also available.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

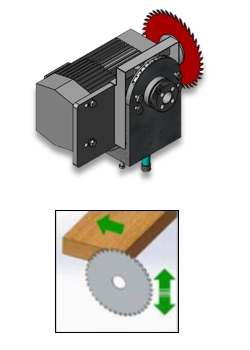

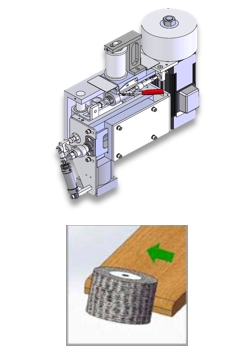

1ST SPINDLE

- Lower Saw Shaft (with retractable blade).

- High-speed variable frequency motor.

- Adjustable angle.

Separated groove (scoring) saw .

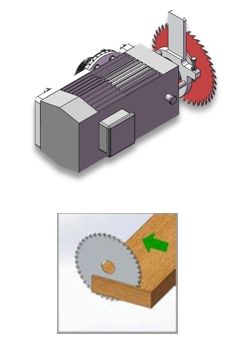

2ND SPINDLE

- Upper Saw Shaft.

- High-speed variable frequency motor.

- Adjustable angle.

- Separated break saw.

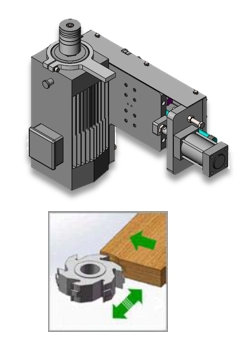

3RD SPINDLE

- Milling Cutter Shaft.

With retractable blade function. - Adjustable angle.

- Equipped with high-speed variable frequency motor .

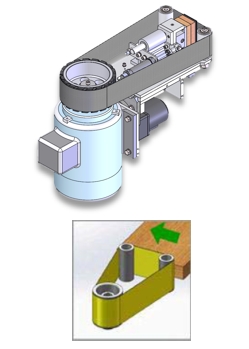

4th SPINDLE

- Milling Cutter Shaft.

- High-speed variable frequency motor.

- Adjustable angle.

5TH SPINDLE

- Triangular Sanding. Frame Assembly

- Sanding wheel center distance: 200mm.

- Automatic belt oscillation function.

- Sanding pressure block with compensation function.

6TH SPINDLE

- Multi-purpose sanding head device.

- Capable of flat sanding or profile sanding.

- Equipped with automatic compensation function.