PROFESSIONAL

50+ years experience

WARRANTY

3 years warranty

SERVICE

tech support 7*12H

SPARE PARTS

standard and unified

Technical PARAMETERS DETAILS

| Model No. | JZHP1400 | JZHP1600 | JZHP1800 | JZHP2000 |

|---|---|---|---|---|

| Blade capacity | 15 – 20T/h | 20 – 30T/h | 30 – 40T/h | 40 – 50T/h |

| Hammer capacity | 10 – 15T/h | 12 – 20T/h | 20 – 30T/h | 25 – 35T/h |

| Blade length | 780mm | 880mm | 650mm | 720mm |

| Number of blades | 6 | 6 | 9 | 9 |

| Number of hammer | 24 | 32 | 40 | 48 |

| Cutter roll speed | / | 650rpm | / | / |

| Machining diameter | ≤400mm | ≤400mm | ≤800mm | ≤800mm |

| Main motor | 185/200KW | 250/280KW | 300/355KW | 355/400KW |

| Feed form | plate chain conveyor | plate chain conveyor | plate chain conveyor | plate chain conveyor |

| Conveying length | 6000mm | 6000mm | 6000mm | 6000mm |

| Feed width | 1400 | 1600 | 1800 | 2000 |

| Discharge width | 1200 | 1400 | 1600 | 1800 |

| Discharge height | 4000mm | 4000mm | 4000mm | 4000mm |

| Conveying length | 8000mm | 8000mm | 8000mm | 8000mm |

| Power | 4-7.5kw | 4-7.5kw | 4-7.5kw | 4-7.5kw |

YOUTUBE VIDEo

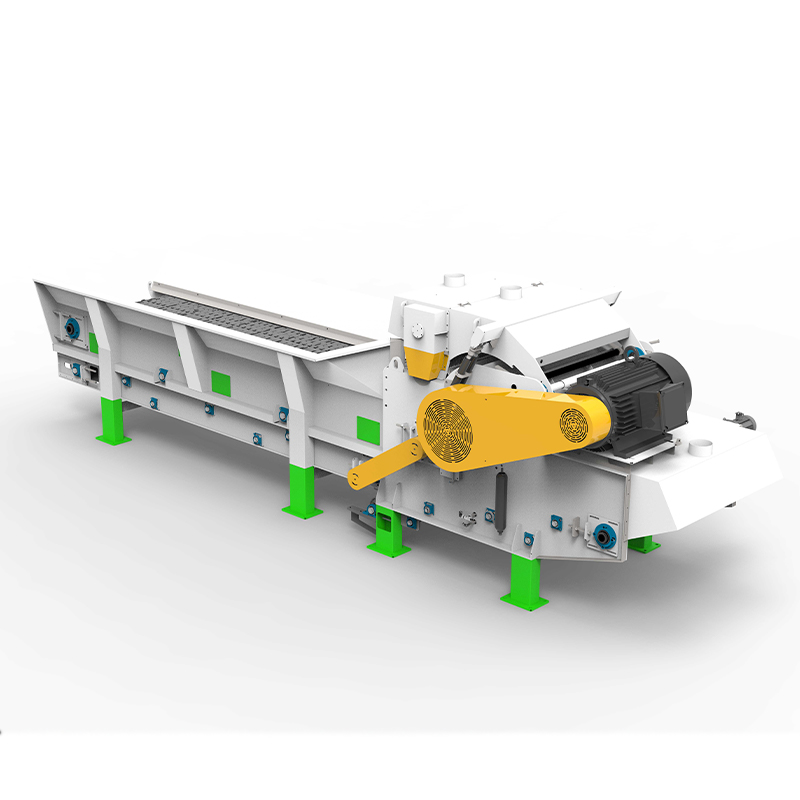

Biomass crusher processing raw materials widely, can process wood, such as all kinds of small wood, board, slats, log core, etc.and all kinds of non-wood raw materials such as all kinds of bulk straw, cotton wood, reed, etc, wide range of application. Comprehensive crusher (hammer type) is not afraid of the nails on the bamboo plywood or cargo tray on the site, is a professional crushing bamboo plywood, waste synthesis on the site, wood pallets and other materials ideal choice. The comprehensive crusher can give these industrial waste and forestry waste to be used twice.

- Adopt chain-plate intelligent feeding, which can automatically adjust the feeding speed according to the load of the main motor, avoid the equipment running with no load and full load, and greatly improve productivity;

- The feeding system adopts direct connection structure, the structure is simple and intuitive;

- The main shaft is made of high-strength alloy steel, which has been heat treated and processed with high precision for many times. It has good mechanical strength and strong anti-fatigue and anti-impact ability.

- Each cutter roll can be disassembled independently, simple and convenient replacement, greatly reducing the workload of workers and improving the continuity of production;

- Stable equipment structure, high processing accuracy, factory test machine calibration, small vibration:

- Extend the bottom feed belt and width, greatly reduce the transmission leakage problem, increase the overall utilization of raw materials.

further information

RELATED PRODUCTS

Powerful Machines & Solutions

Make You More Successful

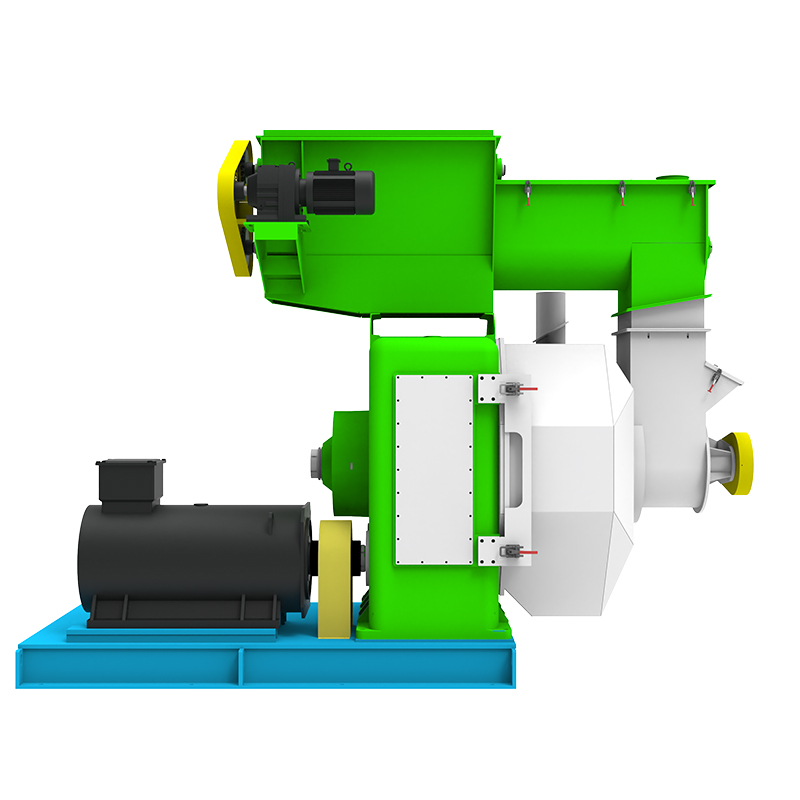

Biomass Pellet Machine

Biomass Pellet Machine

Biomass Comprehensive Crusher

Biomass Comprehensive Crusher

Biomass Pulverizer

Biomass Pulverizer

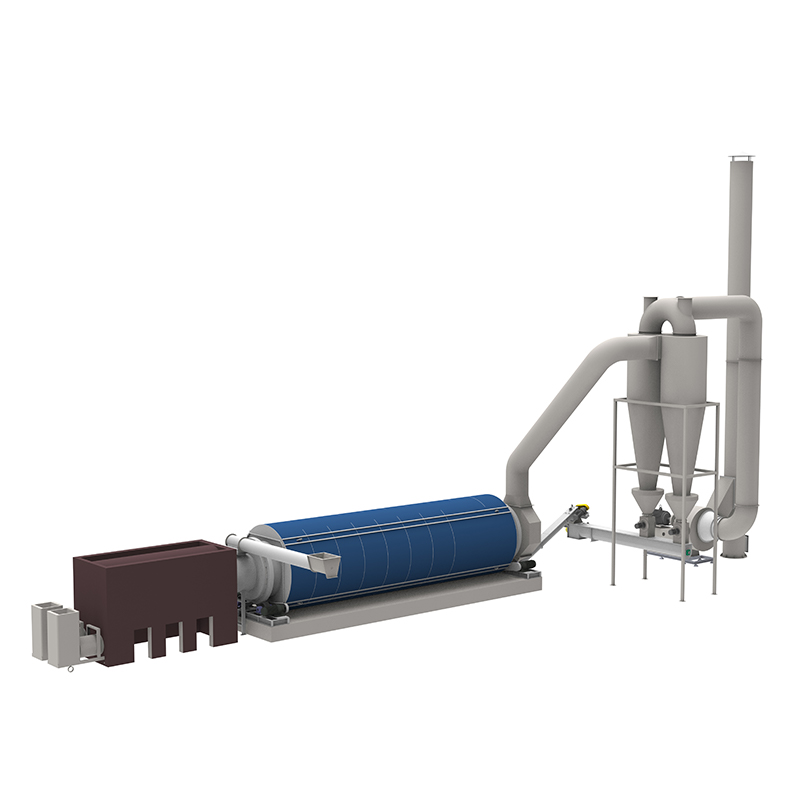

Dryer

Dryer