50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Edge banding machine | 280A |

|---|---|

| banding material thickness | 0.4-1.5mm |

| banding material width | 10-55mm |

| workpiece min. length | 120mm |

| workpiece min. width | 80mm |

| end cutting motor power | 0.37kwx2 |

| fine trimming motor power | 0.75kwx2 |

| buffing motor power | 0.37kwx2 |

| conveyor feeding speed | 12m/min |

| conveyor motor power | 1.5kw |

| total power | 9kw |

| overall size | 3000*750*1270mm |

It’s a automatic edge bander for small board piece.

Overall size is 3000x750x1270mm. Min. workpiece length is 120mm, mini width 80mm. For board edge banding.

Fuction:Gluing/End cutting/ Fine Trimming/ Vertical Scrapping/ Sprayer/ Buffing

1. Touch PC display control.

2. Rotary edge band support disc.

3. The edge band feeding table adopts a single table design.

4. Automatic gluing device.

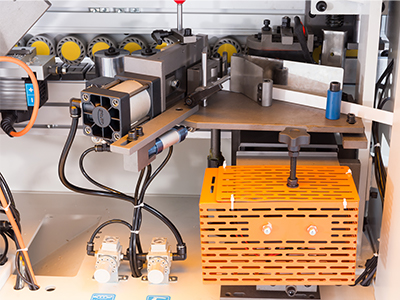

5. Double pneumatic edge banding with pressure roller set, automatic adjustment device, simple and reliable.

6. Adopt imported wide linear guide structure front and back cutting device, high strength and reliable precision

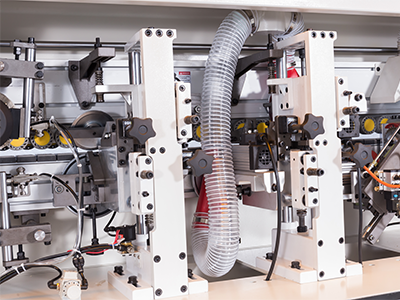

7. Two-head high-speed trimming device 0.35kwX2 (independent high-frequency control, equipped with 2 trimming saw discs)

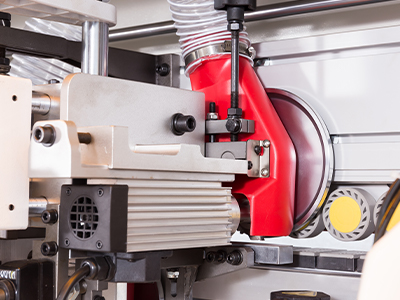

8. Manual adjustment of the upper and lower high-speed finishing device (with digital meter adjustment and display table) 0.7kwX2 (independent high-frequency control, equipped with 2 R2 trimming knives)

9. Up and down vertical scraper device (with 2 R2 scrapers)

10. Up and down polishing device 0.37kwX2 (with 2 polishing cloth wheels)

Delta Colored Touch Screen 7”

Heating light and Gluing part, penematic adjusting

Fast End Cuttiing

Fine tirmming part can equip with diamond cutter head (optional)

Vertical Scarapping+Cleaning Spray+Buffing

Stable Conveyor Motor, machine feeding speed can be 12m/min or 16m/min

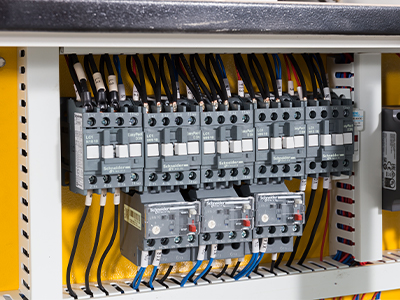

Taiwan Delta Inverters

Taiwan Delta PLC

Schneider Electric Parts

Loading Advantages: (24units in one 40HQ container)