50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | QMB620GH | QMB520GH | |

|---|---|---|---|

| Working width | mm | 20-200 | 20-200 |

| Working thickness | mm | 8-125 | 8-125 |

| Min. working length(intermitent/continuous) | mm | 590/150 | 590/150 |

| Dia. of spindle | mm | φ40 | φ40 |

| Dia. of feeding roller | mm | φ140 | φ140 |

| Feeding speed | m/min | 10-60 | 10-60 |

| Rotation speed of spindle | r/min | 8000 | 8000 |

| Total power | kW/HP | 46.35/62 | 42.6/57 |

| Suction hood dia. | mm | 6*φ120 | 5*φ120 |

| Overall dimensions | mm | 4180*1780*1780 | 3630*1790*1760 |

| Weight | kg | 5100 | 4300 |

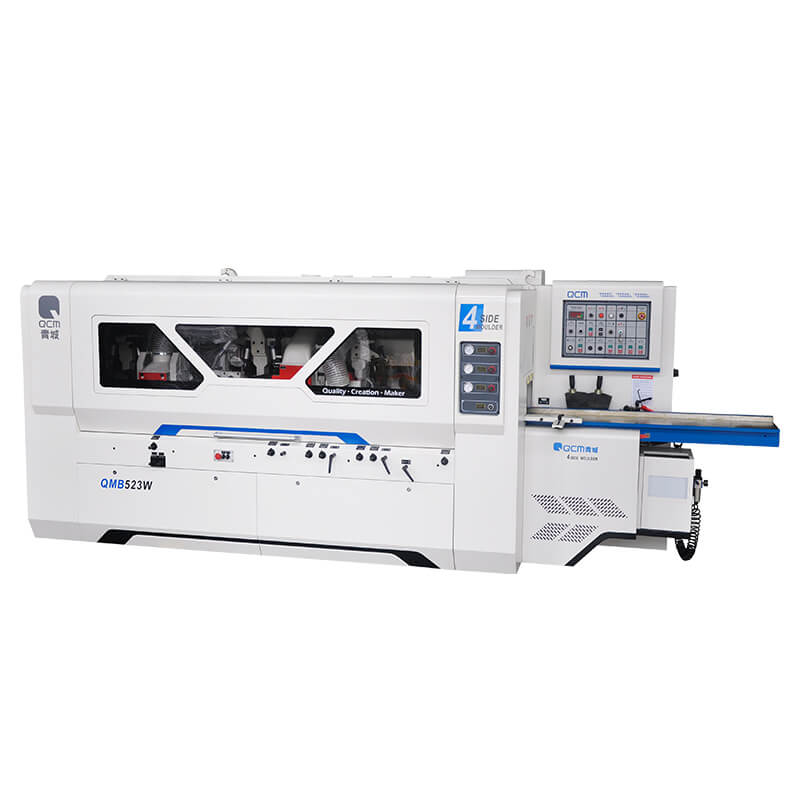

QMB520GH, QMB620GH high speed 4 sided moulder planer machine are perfect solution for mass production of timber or finger joint board manufacturer, maximum working width 200mm.

A lot of finger joint board manufacturer combine QMB620GH 4 sided moulder, and other finger jointing machines together to make an automatic production line, which can save a lot of labor cost, and get much higher productivity.

As a professional 4 sided moulder planer manufacturer, we have 5 spindles, 6 spindles high speed 4 side moulder. They are equipped with a centrifugal feeder or a vertical and horizontal feeder connection to realize automatic feeding four-sided planing processing. In particular, the intermediate worktable of this product adopts a groove positioning and guiding structure, which can overcome the occurrence of material running and jams in the processing of ordinary four-sided planing short materials.

The maximum processing width is 200mm, the maximum processing thickness is 125mm, the shortest processing length is 150mm (continuous), and the feeding speed is 10-60m/min. It has the advantages of high production efficiency and good processing quality. It is the ideal equipment for upgrading and upgrading of the vast solid wood processing finger-joint panel industry.

- The middle worktable adopts a groove positioning structure. After special heat treatment and hard chrome plating, it can reduce the heat of the worktable and ensure the smooth feeding when the shortest processing length is 150mm.

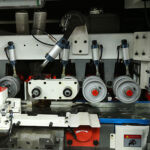

- The movable worktable adopts a cylinder floating active feeding roller structure, which improves the smoothness of the feeding of bent and deformed materials, and realizes high-speed and strong feeding.

- The feeding system is equipped with a high-speed worm gear reducer, universal coupling transmission and imported frequency converter, which realizes variable frequency speed regulation, and the feeding speed can reach 10-60 m/min. Its performance is stable, and the operation is convenient and quick.

- The CLSJ900 side chain conveyor is standard on the outside of the movable table of the main machine to ensure the smoothness of high-speed feeding.

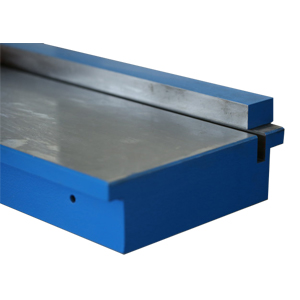

in-feeding table

The in-feeding table of our 4 sided moulder can be lengthened, customized length according to your requirements.

Motor power

In our technical parameter table of planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

in & out feeding

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

casting machine body

4 sided planer has extra heavy one-piece casting iron machine body. It’s specially heat treated for maximum stability and rigidity by standard configuration.

SIEMENS ELECTRICAL

Our 4 sided planer moulders use Siemens and Schneider electrical products and appliances insure the whole machine run well with a suitable performance

airtac cylinder

Pneumatic pressure of the feed rollers can be easily setted to provide an outstanding feeding effect for our 4 sided planer.

SAFETY ENCLOSURE

The full heavy gauge steel sound insulated safety enclosure serves as a chip guard and helps 4 sided planer moulder to reduce noise and has strobe free lighting.

high precision

All spindles are precision constructed and specially heat treated to provide 4 sided moulder maximum cutting stability and permanent accuracy.

heavy duty gearbox

The feed rollers of 4 sided planer are driven through a combination of extra heavy universal shafts and gearbox, ensure no loss of power transmission. A smooth feeding effect is assured.

outstanding feeding

Our planer moulder has more top and bottom powered rollers than most competitor’s four side moulder. And this is an important reason for outstanding feeding performance.

heard-chromed

The entire cast iron chromed in-feed table is heat treated for maximum stability. In-feed table & fence adjustment of 4 sided moulder is quickly accomplished by means of a quick-setting levers.