50+ years experience

3 years warranty

tech support 7*12H

standard and unified

| Specifications | MS3113B | |

|---|---|---|

| Max. length of mortise | mm | 130 |

| Max. depth of mortise | mm | 60 |

| Max. width of mortise | mm | 16 |

| Spindle speed | r/min | 15200 |

| Total power | kW/HP | 2.2/3 |

| Hunting frequency | times/min | 170-230 |

| Air pressure | MPa | 0.4-0.6 |

| Overall dimensions | mm | 1480*1150*1250 |

| Weight | kg | 550 |

1. The fuselage is made of high-quality steel plates welded and processed, and the performance is stable.

2. The spindle adopts high-precision heavy cutting structure, and the spindle speed reaches 15000r/min, with high efficiency.

3. The tenon and groove swinging mechanism adopts the structure of precision cylindrical guide rail sliding bearing, and is equipped with a hand pressure lubricating pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

4. The tongue and groove width adjustment adopts digital display, manual adjustment, simple operation and more accurate processing.

5. The adjustment of the spindle swing speed adopts the friction wheel tensioning speed adjustment structure to adjust the speed to meet the processing needs of various materials.

6. The tenon and groove operation adopts double worktables alternately, and the worktable can process the inclined tenon and groove at an inclined angle.

This product is mainly to meet the needs of tongue and groove processing of solid wood doors, tables and chairs.

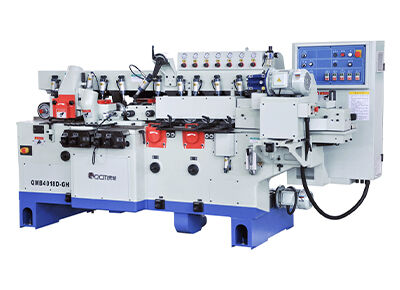

This mortising machine is an economical and practical horizontal double-end slotting machine. The maximum tongue groove width is 130mm, the maximum groove depth is 60mm, and the maximum deep groove width is 16mm. The product has stable performance, simple operation, convenient maintenance and high cost performance. It is an economical and applicable equipment for groove processing in the solid wood processing industry.

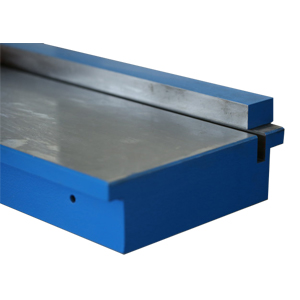

customized table

The in-feeding table of our 4 side planer moulder can be lengthened, customized length according to your requirements.

customized Motor

In our technical parameter table of 4 sided planer moulder, you can see our standard configuration. If you need, we can upgrade motor power for you.

Conveyor system

In order to save labor cost and improve the productivity for you, we can combine 4 sided planer for you with in-feeding and out-feeding system.

Cutting tools

Most of our woodworking machinery has no cutting tools when export, because different woodworking mills need different type of cutters. To improve our service, we can help you buy cutting tools.

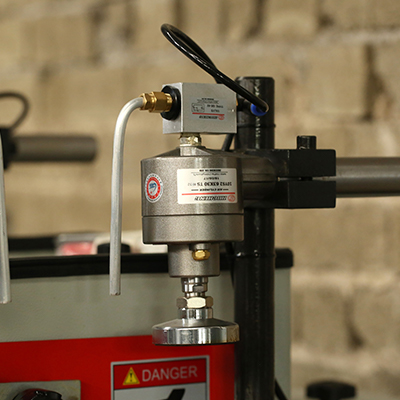

HIGH PRECISION SPINDLE

The spindle adopts a high-precision heavy-cutting structure, and the spindle speed reaches 15000r/min, which meets the needs of high efficiency in mortising processing.

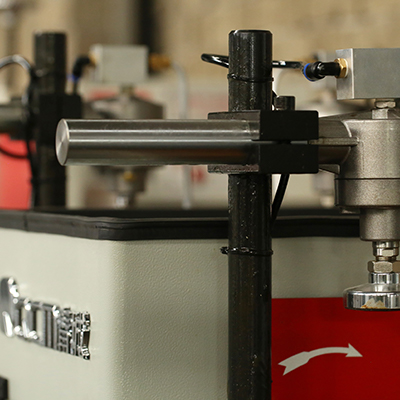

GUIDE RAIL

The mortising mechanism adopts a precision cylindrical guide rail sliding bearing structure, and is equipped with a hand pressure lubrication pump to lubricate the guide rail on time. The mechanism has high swing frequency, high processing efficiency and good quality.

CONVENIENT ADJUSTMENT

The width of the mortising adopts digital display, manual adjustment, simple operation, convenient adjustment and more accurate processing.

SPINDLE SPEED ADJUSTMENT

The adjustment of the spindle swing speed adopts the friction wheel tension adjustment speed structure to adjust the speed to meet the processing needs of various materials.

DOUBLE WORKBENCHES

The mortising operation adopts double workbenches to work alternately, and the workbench can be inclined to process the oblique mortise.